Toothed Drive Belt Tensioning Mechanism with Hydraulic Damping

FROM SERVICE INFO TECH BULLETIN 1983, page 13-14.

The different amounts of drive torque during a revolution of the camshafts

produce oscillation in the toothed drive belt, which could cause belt flatter

and in exceptional cases, when belt tightness is not sufficient, even a jumping

out of the belt.

The new toothed belt tensioner has been designed to hydraulically dampen this oscillation in the toothed drive belt.

Description of Function

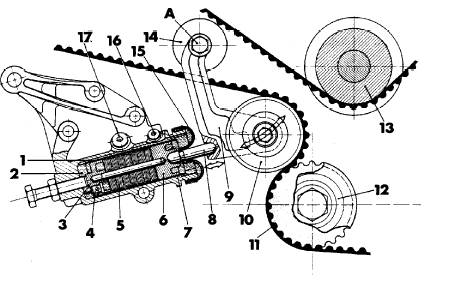

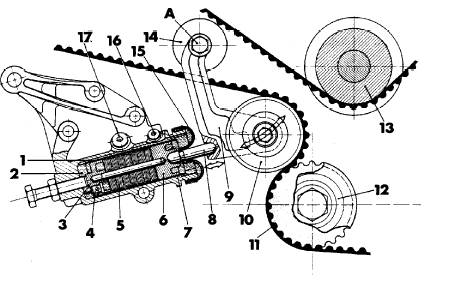

The toothed belt tensioning roller (10) is mounted to turn on the tensioning roller carrier (9).

The tensioning roller carrier pivots around axis A, which is also the pivot

point for contact roller

(14).

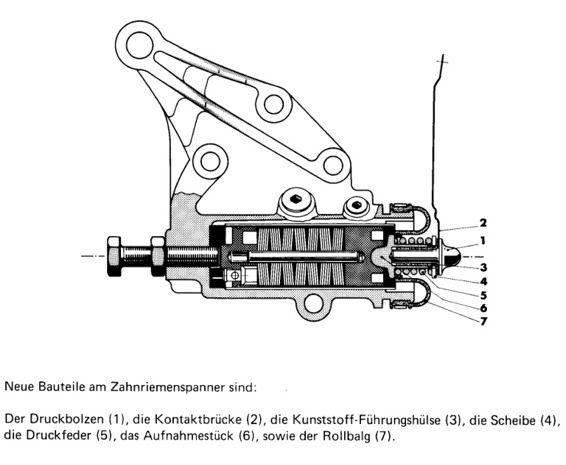

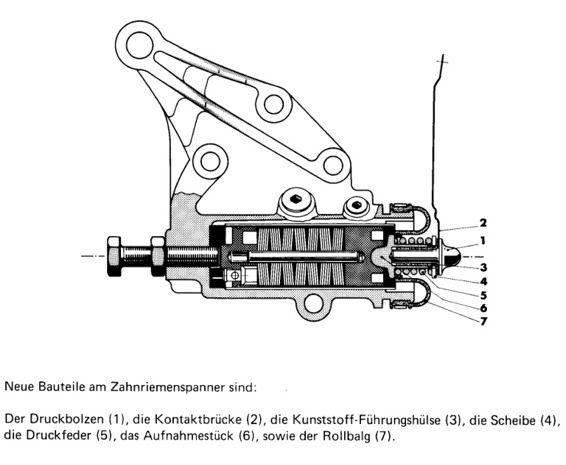

The tensioning roller carrier is supported against pull of the toothed belt (11) via push rod (8) and piston (6) on bimetal diaphragm spring set (5). The entire tensioning roller housing (2) is filled with engine oil.

When toothed belt oscillation causes reaction on tensioning roller (10) and consequently tensioning roller carrier (9), e. g. oscillation in direction of the diaphragm spring set, the push rod (8) and Piston (6) will move in direction of the spring set. The piston now presses against the oil polster and attempts to compress it and the diaphragm springs.

The bimetal diaphragm springs rest on valve carrier (3) and the oil attempts to flow through the bottom valve (4). However, the oil flow also carries the valve along and the chamber is closed completely. Leak oil can still only escape between piston (6) and guide (7).

Three relief bores (1) deliver the leak oil outside along the guide behind the valve carrier (3) again.

In opposite direction, when the push rod moves away from the tensioning

roller housing, the bottom valve opens and allows undamped oil to flow through

the valve carrier.

MAINTENANCE INSTRUCTIONS

The new toothed drive belt tensioning mechanism is filled with engine oil.

The pockets in the engine block and tension roller housing are used as oil

chambers. This improves the heat transfer between the engine block and tension

roller housing and activates the bimetal diaphragm springs.

This requires that the sealing surfaces of both parts be in perfect

condition.

The sealing surface of the tensioning roller housing must be treated with

Loctite No. 574 during assembly.

Tensioning roller housings are supplied as replacement parts without the oil

filling.

The oil can only be added after installation on the engine block.

To guarantee complete filling of the damping chamber, it is necessary that air

be pumped out of the damping chamber by pumping action of the tensioning roller

carrier (9) with a loosely installed toothed drive belt and an open oil filler

bolt (17) and bleeder (16).

This procedure can be supported by tilting the engine on an assembly stand until the cylinder chamber of the tensioning roller housing is horizontal. A small air trap behind the rubber cap (15) is not dangerous, but in fact desired as a compressible pressure compensation.

The oil level must be checked at 20,000 kilometer intervals during inspection

work.

Oil does not have to be added, if oil can be seen after unscrewing the filler

bolt (17).

However, if oil does have to be added, also unscrew the bleeder screw (16) in

addition to the oil filler bolt.

If the hydraulic damping fails because of insufficient oil, the toothed belt tensioning mechanism will function as the former system without damping.

Note:

The new toothed drive belt tensioning system can also be applied in older

models, if the pertinent sealing surfaces of the engine block are not damaged.

Note: the tensioner to block surfaces now use a gasket for sealing and engine oil rather than the

90 wt gear oil used prior to 1983.

-----

Thanks to Tony Harkin for the great work or art, and sharing it....

=====

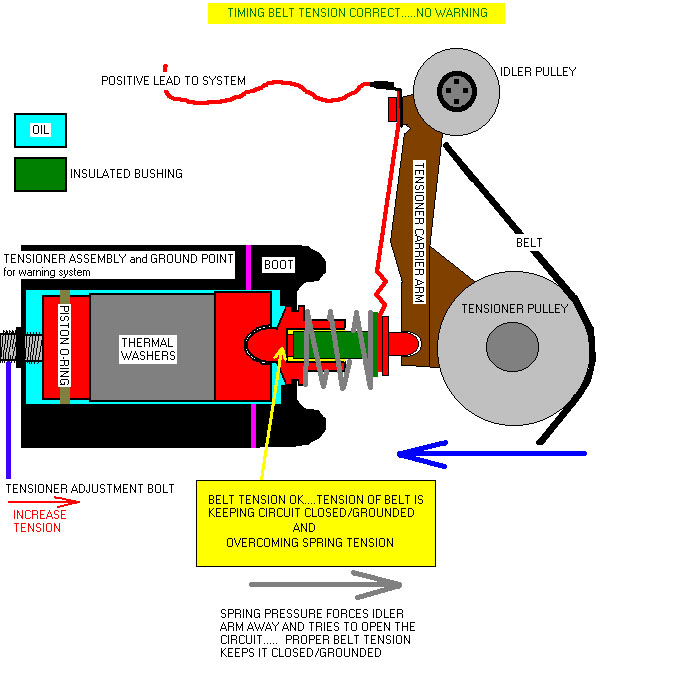

The primary function of the tensioner is to compensate for the thermal growth

of the aluminum engine block and cylinder heads - the block grows more than the

belt, which would cause too much tension when the engine was hot, or too little

tension when the engine was cold.

The bimetallic washers flatten slightly with increasing temperature, and Porsche

found that the later cars needed more compensation, so more washers were added.

At that time, they also arranged for the oil to flow into a blind recess in the

block to increase heat transfer, and added seals and check valves to increase

the dampening effect to reduce belt flutter as the oil is pumped around. It is,

according to Porsche, a dynamic device.

The tensioner used on the earlier cars should have 90 wt gear oil poured in when

it is installed. The later tensioners should have engine oil pumped in through

the bleed nipples. The oil furnishes heat transfer, dampening, and lubrication.

The tensioner should be rebuilt every time that the belt is changed.

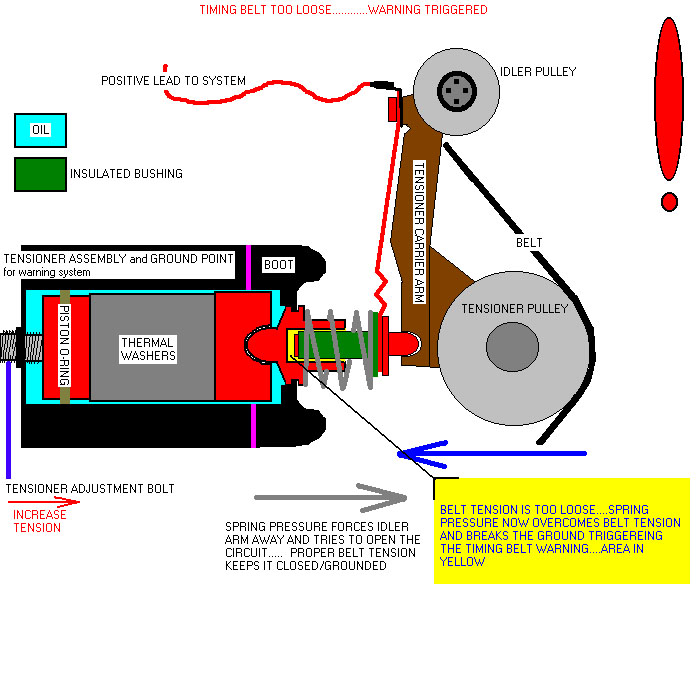

I know of no way to calibrate the tension warning system. The trigger mechanism

consists of a short, heavy coil spring on the plunger that pushes the tensioner

arm. As long as there is adequate tension, the spring is compressed and the wire

from the warning computer is grounded.

When tension is inadequate, the spring expands enough to push the wire

connection away, and the wire is no longer grounded.

Wally Plumley

928 Specialists

www.928gt.com