|

|

|

Wheels and Rims

Measuring a 5-bolt pattern: A 5-bolt pattern is very difficult to measure without using a bolt pattern gauge. Basically, you would measure the diameter of a circle that crosses through the center of the lug holes. This method is not recommended to confirm wheel fitment.

|

Items required to measure wheel backspace:

|

||

| The easiest way to measure backspace is to lay the wheel face down onto the ground so the backside of the wheel is facing up. Take a straight edge and lay it diagonally across the inboard flange of the wheel. Take a tape measure and measure the distance from where the straight edge contacts the inboard flange to the hub mounting pad of the wheel. This measurement is backspace. The above photo shows three wheels with 2",3", & 4" backspace. | |||

|

Measuring Wheel OffsetTo calculate offset you'll need the following measurements:

Subtract:

Tip:

|

||

|

Backspace to Offset Conversion Chart

The table on the right is q quick reference for finding offset, pick the rim width and follow the row over to the backspace of your wheel. |

||

| Fitting a wheel and tire package is different

for each vehicle, but by following these guidelines your chances for

success will be much greater. In most cases you'll have to use the

physical dimensions of the current wheel/tire package to determine the

dimensions of the new wheel/tire package.

Items which are potential trouble spots:

|

|||

|

In the drawing on the left, we've made two

measurements

These measurements when used with:

Help determine if wheel/tire clearance is adequate for the new wheel/tire package you've selected |

||

| Suggestion: Start your search for new wheels by picking the tires first. Get the tire manufacturer's rim width recommendations and physical dimensions for the tires you want. Pay close attention to Section Width and Measured Rims specs., these are important numbers to be used when selecting rims and determining vehicle fitment. | |||

| Ensuring proper caliper clearance inside the wheel is important. The following chart should enable you to have the dimensions required by most wheel manufactures. | |||

|

|

||

|

|

||||||||||||||||

| IMPORTANT NOTICE: As with all types of wheels retorque lug nuts after the first 25 miles & at 100 mile intervals until lug torque is maintained. | |||||||||||||||||

| Note: Always refer to Owner's Manual for proper factory specifications that take precedence over the listed recommendations. | |||||||||||||||||

|

|||

|

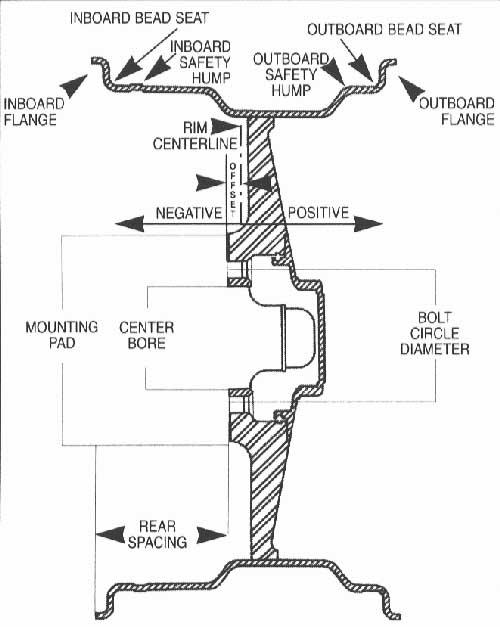

Bolt pattern or lug pattern or bolt circle is determined by the number of bolt holes and the bolt circle diameter. Hub Diameter or center bore is the hole at the center of the wheel. Rear spacing or back spacing is the distance from the backside of the wheel mounting pad to the outside of the rim flange. Offset: The distance from the centerline of the wheel to the mounting surface of the wheel. Negative offset: When the back of the bolt pad is closer to the inside of the wheel; when mounting surface is inboard of the rim centerline. Positive offset: When the back of the bolt pad is closer to the street side of the wheel; when the mounting surface is outboard of the rim centerline. | |||

| Bead-Loc A device which captures the tire bead between it's flanges, usually secured by bolts to keep tire bead from dismounting. Usually used in dirt circle track or off road applications where low tire pressures are used and hitting ruts or other vehicles are common. Left: An example of a Bead-Loc wheel |

|

||

Two & Three piece modular wheels require

periodic maintenance. You'll want to work out your own maintenance

schedule, but here's an example of what the manufacturer recommends.

|

|||

| Below is an example of cracking which can occur on wheels which don't support the back rim half with the center. This wheel happens to be a Dura-lite wheel. |

|

||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| |

|

|

| |

|

|

||

|

|

||

|

|

||