Porsche patent for the 1987 S4 crankcase breather system

Crankcase ventilation system for motor vehicles

US 4753214 A

ABSTRACT

A crankcase ventilation system for motor vehicles comprises a main ventilation

system and a safety ventilation system, in which at an air guiding housing of

the intake system, connecting pieces are arranged to which the lines of the two

systems are connected. So that the connection between the lines of the two

systems and the air guiding housing is simplified with respect to construction

and also requires little space, a joint connecting piece having connecting pipe

sections for the lines of both systems is provided at the air guiding housing.

Separate ducts lead away from the connecting pipe sections and extend to

remotely arranged outlet openings. The outlet openings of both ducts--seen in

flow direction--extend at a distance from one another.

CLAIMS(15)

What is claimed:

1. A crankcase ventilation system for motor vehicles, in which the crankcase

gases are returned from the cylinder block and crankcase into an air guiding

housing of an intake system of an internal-combustion engine via a main

ventilation system or a safety ventilation system for accommodating blockage of

the main ventilation system, comprising

a main intake line connected to the main ventilation system and the crankcase,

a safety intake line connected to the safety ventilation system and the

crankcase in by passing relation to the main intake line, and

a common connecting piece for connecting the air guiding housing with both the

main intake line and the safety intake line.

2. A crankcase ventilation system according to claim 1, wherein said common

connecting piece includes respective separate ducts which lead away from

connecting pipe sections for the main intake line and the safety intake line,

said separate ducts extending to remotely arranged outlet openings, and wherein

outlet openings of the ducts, seen in flow direction, extend at a distance to

one another and lead into the air guiding housing.

3. A crankcase ventilation system according to claim 2, wherein the connecting

piece is developed to be approximately Y-shaped.

4. A crankcase ventilation system according to claim 2, wherein a duct of the

safety ventilation system extends as a continuation of a pertaining connecting

pipe section and has a straight shape.

5. A crankcase ventilation system according to claim 2, wherein a duct of the

main ventilation system surrounds a duct of the safety ventilation system.

6. A crankcase ventilation system according to claim 5, wherein the two ducts of

the main ventilation system and the safety ventilation system are arranged

eccentrically with respect to one another.

7. A crankcase ventilation system according to claim 5, wherein wall sections of

the ducts of the main ventilation system and the safety ventilation system rest

against one another along portions thereof.

8. A crankcase ventilation system according to claim 2, wherein a outlet opening

of the main ventilation system, seen in flow direction, is arranged in front of

an outlet opening of the safety ventilation system.

9. A crankcase ventilation system according to claim 1, wherein a duct of the

main ventilation system and an assigned connecting pipe section are placed

against one another at an angle.

10. A crankcase ventilation system according to claim 2, wherein a duct of the

main ventilation system is developed to be closed at the side that is opposite

its outlet opening.

11. A crankcase ventilation system according to claim 2, wherein the connecting

piece is inserted into a pipe section of the air guiding housing and is

connected with it via a locking connection.

12. A crankcase ventilation system according to claim 2, wherein a duct of the

safety ventilation system, with its free end containing an outlet opening,

projects with portions thereof into the interior of the air guiding housing.

13. A crankcase ventilation system according to claim 2, wherein an end of the

duct containing an outlet opening is arranged outside an interior limiting wall

in the area of the pipe section.

14. A crankcase ventilation system according to claim 2, wherein the air guiding

housing is formed by an air guiding scoop arranged between an air mass meter and

a throttle valve pipe section.

15. A crankcase ventilation system according to claim 1, wherein said common

connecting piece is a unitary one-piece molded part that includes respective

main intake and safety intake ducts connecting the main intake line and the

safety intake line to different outlet openings in the air guiding housing.

DESCRIPTION

BACKGROUND AND SUMMARY OF THE INVENTION

The invention relates to a crankcase ventilation system for motor vehicles, in

which the crankcase gases are returned from the cylinder block and crankcase

into an intake system of an internal-combustion engine via a main ventilation

system or a safety ventilation system. Connecting pieces are arranged at an air

guiding housing of the intake system for connecting lines of the main

ventilation system and of the safety ventilation system.

In the case of a known crankcase ventilation system (Service Information 1985,

Porsche 928 S, USA, Pages 30 and 31) of the initially mentioned type, two

connecting pieces arranged at a spacing from one another are provided at the air

guiding housing of the intake system, one connecting piece being connected with

the line of the main ventilation system and the other connecting piece being

connected with the line of the safety ventilation system. This crankcase

ventilation system functions well, but the construction of the air guiding

housing with the two connecting pieces is costly. In addition, the two

connecting pieces require considerable space at the air guiding housing so that

the narrow space conditions that anyhow are present particularly in the area of

the intake system of a four-valve engine are limited even more.

It is an objective of the invention to take such measures at a crankcase

ventilation system that the connection between the lines of the two systems and

the air guiding housing is simplified with respect to construction and also

requires little space.

According to the invention, this objective is achieved by providing a common

connecting piece that connects both crankcase ventilation systems with the air

guide housing. In certain preferred embodiments, the common connecting piece has

outlet openings to the air guide housing that are spaced from one another in the

vented gas flow direction. The preferred embodiments of the invention have a

unitary connecting piece with a Y-shape, the arms of the y connecting

respectively to the two ventilation systems.

The main advantages achieved by means of the invention are that by the

arrangement of only one connecting piece for the lines of both systems, a simple

and space-saving connection is established between the lines and the air guiding

housing. By means of the separate ducts inside the connecting piece for the two

systems and the outlet openings that are offset with respect to one another, a

good functioning of the crankcase ventilation system is achieved. When the

outlet opening of the main ventilation system is, for example, closed by ice,

the safety ventilation system with the outlet opening that in sections projects

into the inside of the air guiding housing will take over the crankcase

ventilation until the closed connection of the main ventilation system in the

air guiding housing has become penetrable again after the engine operating

temperature or a sufficient engine compartment temperature has been reached. The

connecting piece can be constructed in an easy and cost-effective way. Because

of the locking connection between the connecting piece and the short pipe

section of the air guiding housing in certain preferred embodiments, a rapid and

easy mounting of the connecting piece is ensured.

Other objects, advantages and novel features of the present invention will

become apparent from the following detailed description of the invention when

considered in conjunction with the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

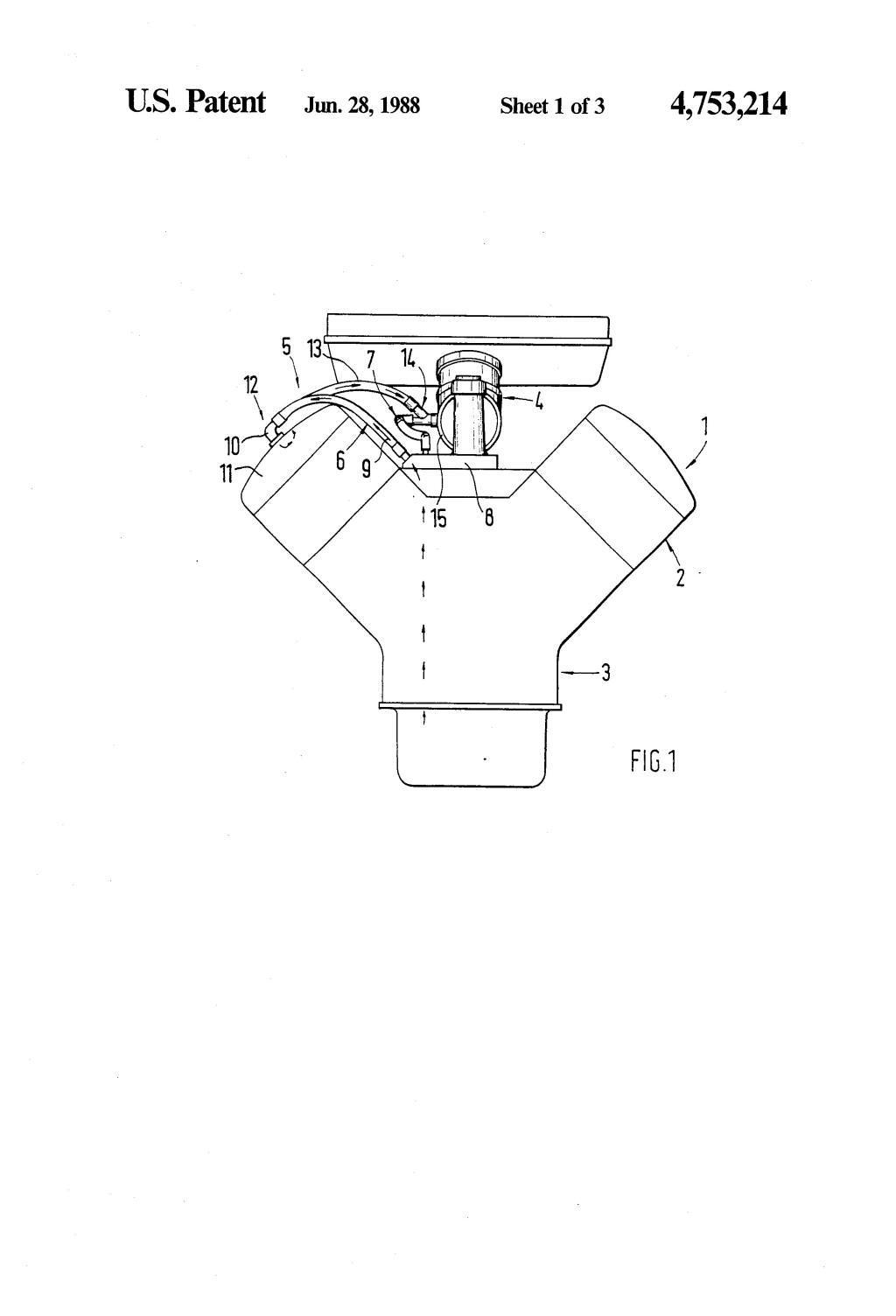

FIG. 1 is a frontal schematic view of an internal-combustion engine having a

crankcase ventilation system constructed in accordance with a preferred

embodiment of the invention;

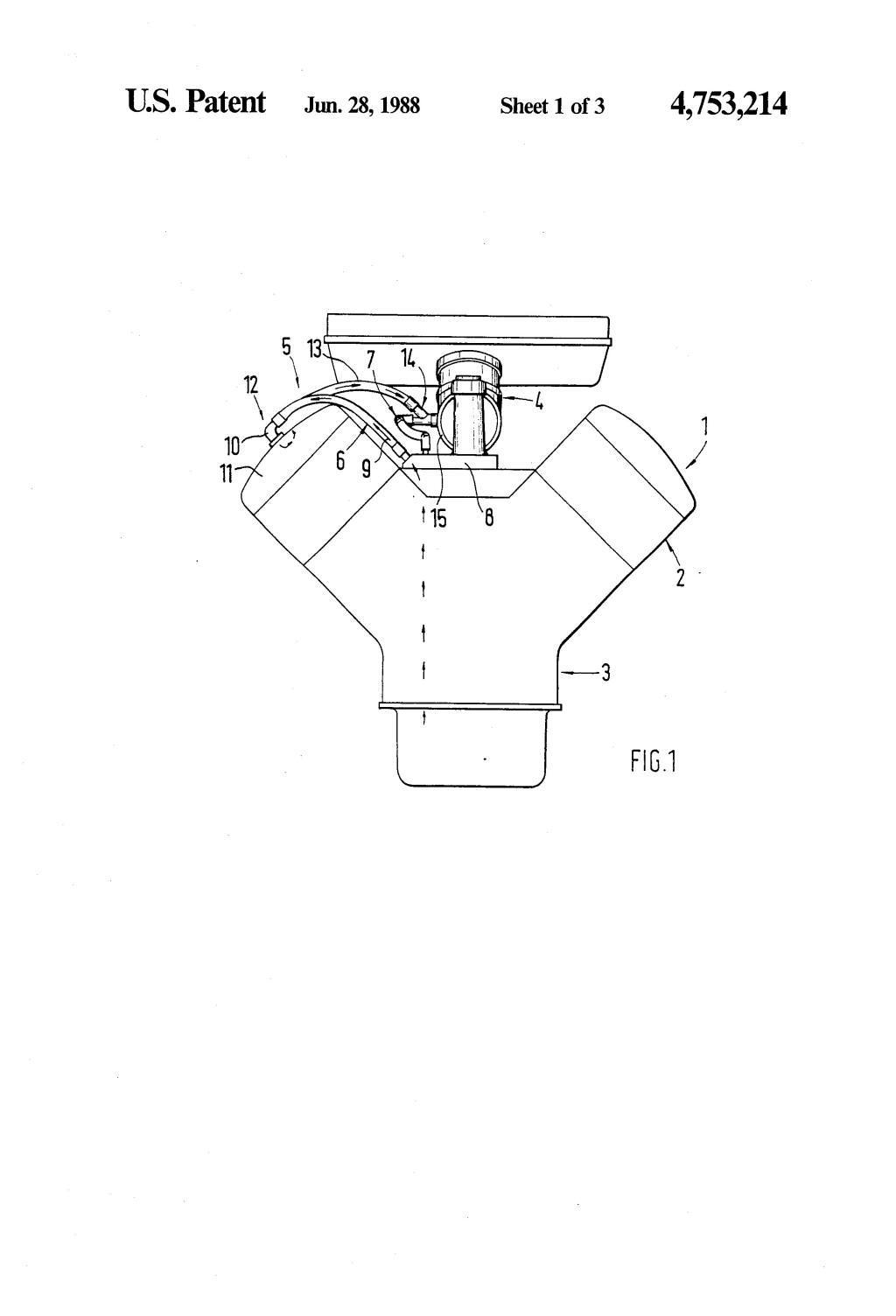

FIG. 2 is a diagrammatic view from above onto the crankcase ventilation system of FIG. 1;

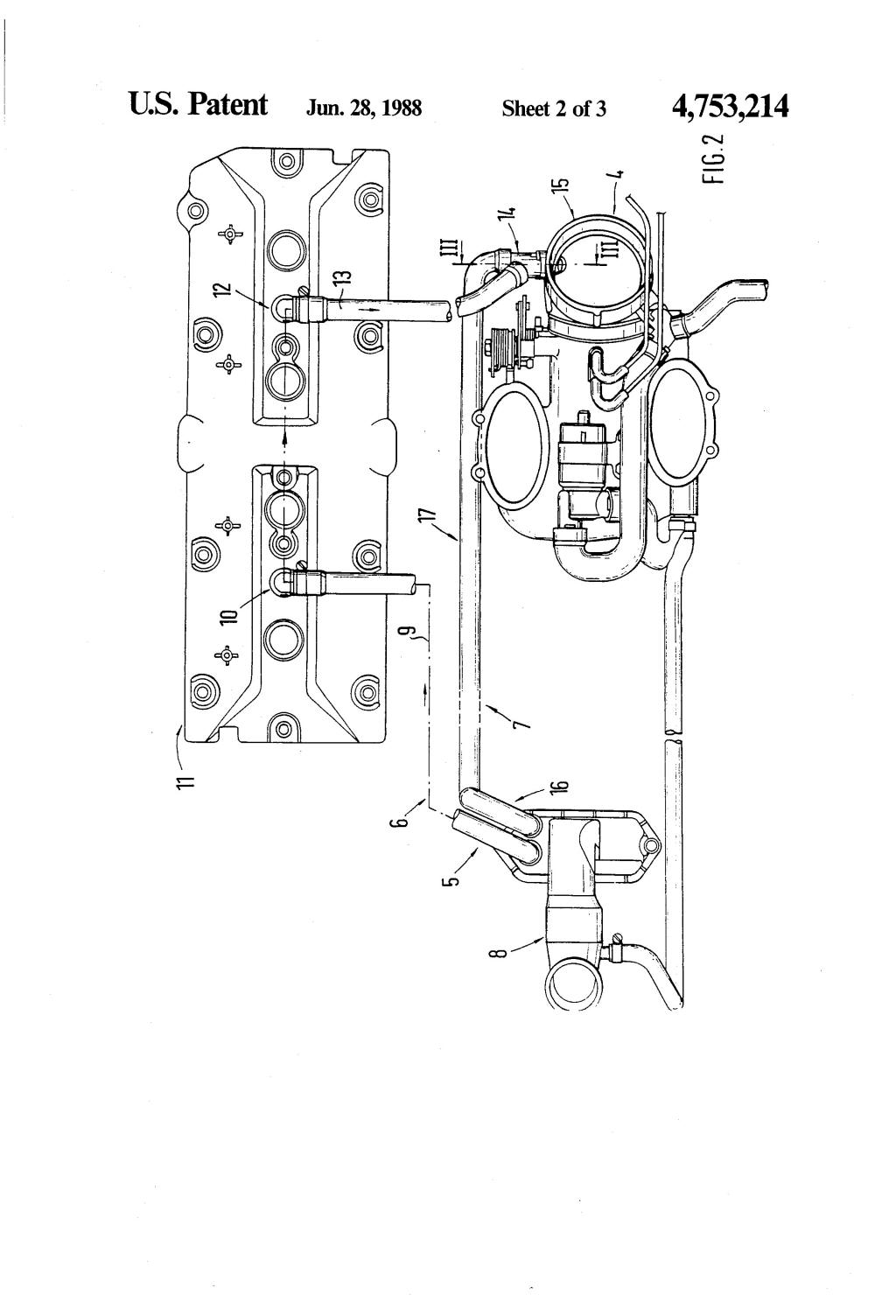

FIG. 3 is a sectional view taken along the Line III--III of FIG. 2; and

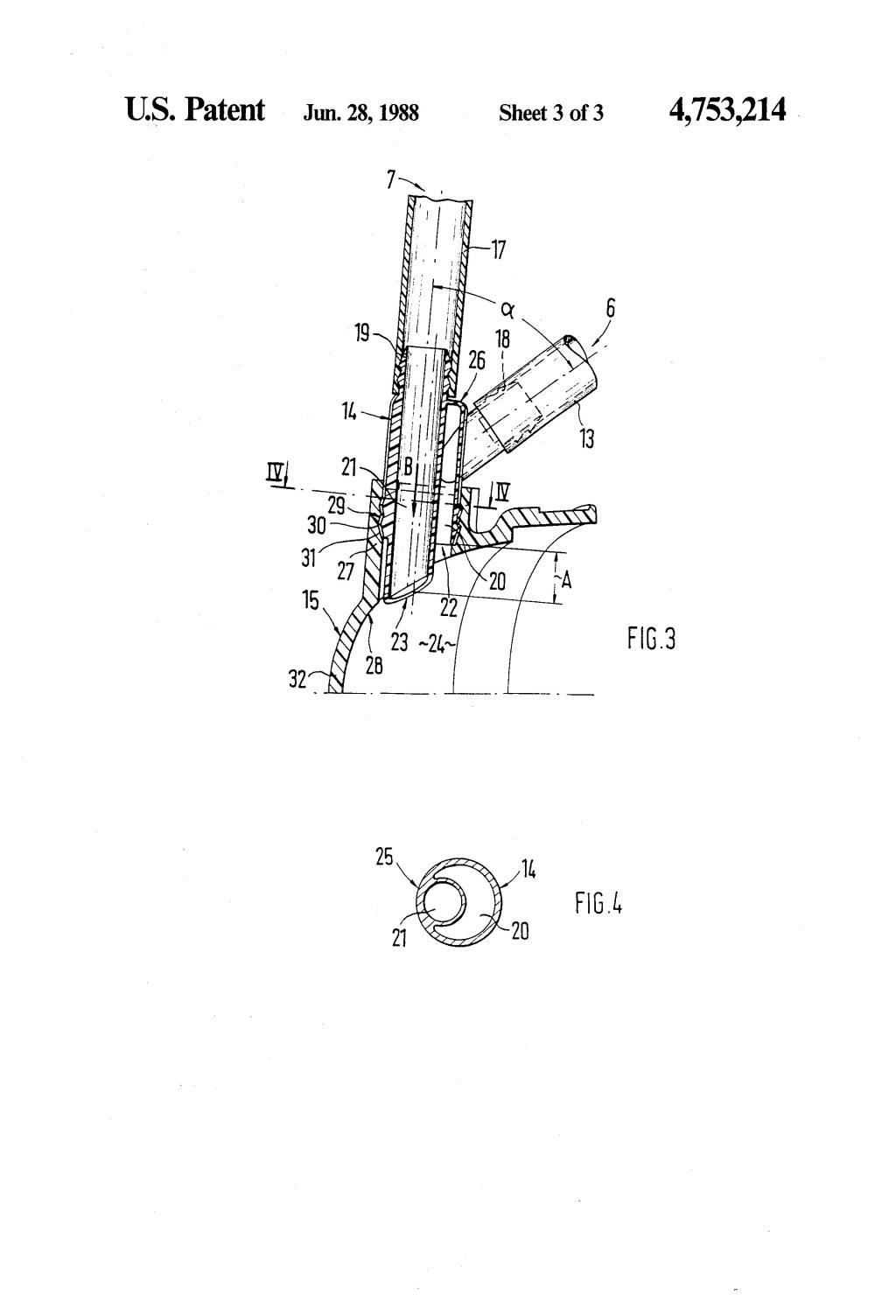

FIG. 4 is a sectional view taken along the Line IV--IV of FIG. 3.

DETAILED DESCRIPTION OF THE DRAWINGS

A multicylinder internal-combustion engine 1 for a motor vehicle comprises a

cylinder head 2 and a cylinder block and crankcase 3. For the return of the

crankcase gases from the cylinder block and crankcase 3 into an intake system 4

of the internal-combustion engine 1, a crankcase ventilation system is provided

that is composed of a main ventilation system 6 and a safety ventilation system

7.

In the case of the main ventilation system 6, the crankcase gases (blow-by

gases) move from the cylinder block and crankcase 3 into an oil filler neck 8.

Subsequently, they pass through a line 9 that is connected via an angle

connection 10 with a cylinder head cover 11 that penetrates it. Inside the

cylinder head cover 11, between the two central cylinders, an oil separator is

arranged that is not shown in detail. After flowing through the oil separator,

the crankcase gases, via another angle connection 12 and a line 13 arranged

outside the cylinder head cover, reach a connecting piece 14 that is arranged at

an air guiding housing 15 of the intake system 4. Inside the angle connection

12, a throttle is inserted that is not shown.

When the main ventilation system 6 fails, for example, caused by icing (=closing

of the throttle bore and/or of the outlet opening of the connecting piece), the

excessive pressure in the cylinder block and crankcase 3 will rise because of

lacking pressure balance and the safety ventilation system 7 will be actuated.

In the case of the safety ventilation system 7, the crankcase gases, via an

opening of the cylinder block and crankcase 3 that is not shown, will reach the

oil filler neck 8. At 16, a safety valve is inserted into a connection of the

oil filler neck 8 that opens at an excessive pressure of 80 to 100 mbar. When

the safety valve is open, the crankcase gases, via a line 17, flow directly to

the air guiding housing 15 (FIG. 2).

According to FIGS. 2 and 3, a joint connecting piece 14 having respective

connecting pipe sections 18, 19 for the lines 13, 17 of the two systems 6, 7

(main ventilation system and safety ventilation system) is provided at the air

guiding housing 15, in which case separate ducts 20, 21 lead away from the two

connecting pipe sections 18, 19 and extend to remotely arranged outlet openings

22, 23. The two connecting pipe sections 18, 19 extend at an angle to one

another. The outlet openings 22, 23 of the two ducts 20, 21, seen in flow

direction B, extend at a distance A to one another and lead into the air guiding

housing 15. Duct 21 of the safety ventilation system 7 that is shaped in a

straight line extends as a continuation of the connecting pipe section 19 and

with its free end containing the opening 23, in sections, projects into the

interior space 24 of the air guiding housing 15. The cross-section of the duct

21, seen over its whole longitudinal course, is constant. The duct 20 of the

main ventilation system 6 surrounds the duct 21 of the safety ventilation system

7 in sections, in which case the two ducts 20, 21 are arranged eccentrically

with respect to one another. Wall sections of the interior duct 21 and of the

exterior duct 20 are merged together at 25. The exterior duct 20 has an

approximately crescent-shaped cross-section (FIG. 4).

The connecting pipe section 18 of the main ventilation system 6 extends at an

angle to the connecting duct 20, the side 26 of the duct 20 that is opposite the

outlet opening 22 being developed to be closed. The outlet opening 22 of the

main ventilation system 6, seen in flow direction B, is arranged in front of the

outlet opening 23 of the safety ventilation system 7, in such a way that the

outlet opening 22 of the main ventilation system 6 extends in the area of a

connecting pipe section 27 of the air guiding housing 15. The outlet opening 23

of the safety ventilation system 7 extends approximately in parallel to an

interior limiting wall 28 of the air guiding housing 15.

The approximately Y-shaped connecting piece 14 is inserted into the molded-on

connecting pipe section 27 of the air guiding housing 15 and connected with it

via a locking connection 29. The locking connection 29 comprises groove-shaped

molded-on parts 30 at the connecting piece 14 that engage in corresponding

recesses 31 of the connecting pipe section 27. The air guiding housing 15 is

formed by an air guiding scoop 32 developed in the shape of a pipe section

connection that is arranged between an air mass meter and a throttle valve

connection piece, namely below a throttle valve that is not shown.

Although the present invention has been described and illustrated in detail, it

is to be clearly understood that the same is by way of illustration and example

only, and is not to be taken by way of limitation. The spirit and scope of the

present invention are to be limited only by the terms of the appended claims.

PATENT CITATIONS

Cited Patent Filing date Publication date Applicant Title

US2311036 * 27 May 1940 16 Feb 1943 Dick Wills Engine breather and ventilating

system

US3059628 * 13 Dec 1960 23 Oct 1962 William J Linn Gas and fume disposal system

for internal combustion engines

US3372685 * 5 Dec 1966 12 Mar 1968 Ardell T. Bestland Excessive crankcase

pressure warning system and relief valve

US4011846 * 24 Mar 1975 15 Mar 1977 Did-Mor Engineering And Manufacturing Co.

Anti-pollution device

DE3627376A1 * 12 Aug 1986 18 Feb 1988 Unilever Nv Bundle of a plurality of

individual packs, and method for its manufacture

* Cited by examiner

NON-PATENT CITATIONS

Reference

1 * Porsche, Information Service 1985, 928S USA, Jun. 1985, pp. 30 & 31.

* Cited by examiner

REFERENCED BY

Citing Patent Filing date Publication date Applicant Title

US5140968 * 14 Feb 1992 25 Aug 1992 Navistar International Transportation Corp.

Closed loop breather system for engine crankcase

US8151777 29 Oct 2008 10 Apr 2012 Toyota Jidosha Kabushiki Kaisha Intake pipe

structure of internal combustion engine

CN1298968C * 15 Apr 2004 7 Feb 2007 日产自动车株式会社 Internal-combustion engine with

cylinder mixing air recycle system

CN101230792B 22 Jan 2008 29 Dec 2010 通用汽车环球科技运作公司 Engine PCV system with venturi

nozzle for flow regulation

CN101539044B 18 Mar 2009 30 Nov 2011 丰田自动车株式会社 用于内燃发动机的电控窜缸混合气返回装置

EP0874141A1 * 9 Apr 1998 28 Oct 1998 Daimler-Benz Aktiengesellschaft Venting

device for the pipe connected to the intake manifold of a combustion engine

EP1469171A2 * 14 Apr 2004 20 Oct 2004 Nissan Motor Company, Limited Internal

combustion engine with blow-by gas recirculation system

WO2009084144A1 * 29 Oct 2008 9 Jul 2009 Toyota Motor Co Ltd Intake pipe

structure of internal combustion engine

* Cited by examiner

CLASSIFICATIONS

U.S. Classification 123/572

International Classification F02F7/00, F01M13/00, F02B75/22, F01M13/02

Cooperative Classification F02F7/006, F01M13/00, F02B75/22, F01M13/025

European Classification F01M13/00

LEGAL EVENTS

Date Code Event Description

10 Sep 1996 FP Expired due to failure to pay maintenance fee

Effective date: 19960703

30 Jun 1996 LAPS Lapse for failure to pay maintenance fees

6 Feb 1996 REMI Maintenance fee reminder mailed

30 Sep 1991 FPAY Fee payment

Year of fee payment: 4

12 Jun 1987 AS Assignment

Owner name: DR. ING. H.C.F. PORSCHE AKTIENGESELLSCHAFT, PORSCH

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNORS:LANGLOIS,

KARL;BATZILL, MANFRED;REEL/FRAME:004725/0879

Effective date: 19870604

=====

There are a number of important features in this original concept. The rear

passenger valve cover breather (patent figure 12) has a volume separator inside

the valve cover (not displayed in the drawing) and approximately 6mm metering

orifice in the elbow. The connection (patent figure 16, 7, 17) has a check valve

with approximately 1-1.5 psi cracking pressure. The from passenger valve cover

breather (patent figure 10, 9, 6, 5) has no separator and no metering orifice.

The connection from the oil filler neck to the intake manifold plenum has an

approximately 2mm metering orifice.

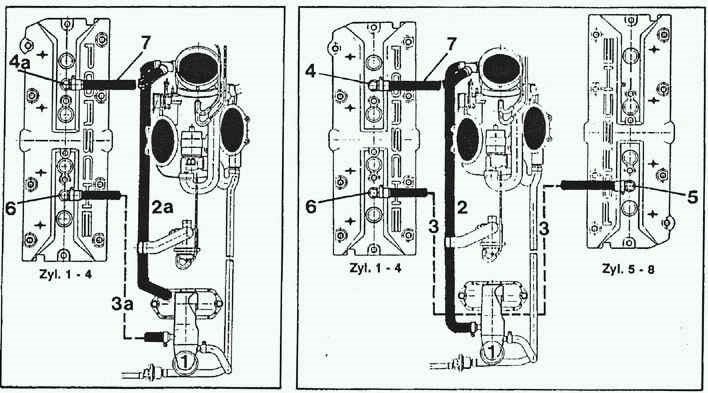

Subsequently, multiple different variations of this system were produced. The

two later ones are describes in the below figure from the workshop manual:

While the implementation in the early GTS engines on the left is more faithful to the original concept, the implementation on the righ

t for the later GTS engines deviated significantly from the original concept.

A connection between valve covers is added, a check valve is eliminated, etc.

The GTS engine breather system is broadly considered a failure, but it is not

clear whether this is because of the external breather system per se or some

other, more fundamental problems with the engine design.

The early S4 crankcase breather system that closely corresponds to the system

originally described in the patent documents works somewhat adequately if the

engine, including the engine redline, is stock and if the car is run on stock

tires at moderate lateral accelerations. If the engine rpm is increased or other

changes made, problems often appear. Subsequent GT models had more serious

problems in even their stock form.

The lateral accelerations are relevant for the following reasons. In a 90-degree

V8 engine, the oil drains from the cylinder heads are in approximately 45-degree

angle relative to the vertical plane. In a 1g lateral acceleration, from the oil

drain perspective the engine is effectively turned sideways with the oil drains

horizontal on the outside turn bank of the engine. In this situation, there is

no gravity drain, and the pressure differential between the crankcase and the

head mostly determines in which direction the oil flows. If the crankcase

pressurizes and the heads are relieved, it is logical to assume that the oil

will flow into the heads instead of the sump.

In addition, the piston pumping pulses create havoc in the oil drains. It is

possible that if blow by gasses increase the pressure and density of the

crankcase and high rpms then increase the energy delivered by the piston pumping

pulses, the oil may be ejected from the oil drains into the heads. The

combination of high blow by rates, high engine speeds, and relatively low

pressure in the heads compared to the crankcase may lead to oil drain problems

so significant that the oil pump pickup in the sump will be starved of oil,

resulting in engine failure.

I believe that the GT and S4 modelsí crankcase breathing problems can be mostly

resolved by redesigning the external crankcase breather system. Higher the

operating rpms and higher the lateral accelerations, more extensive the required

internal engine modifications. However, the engine internals of GT and S4 models

are adequate for most uses, while improvement are of course possible.

The GTS engine has many issues relating to oil consumption and crankcase

breathing, and I believe those aren't caused mainly by the breather system and

in any case can't be cured with minor tweaks of the stock breather system. I

believe that one problem in the GTS engine is the crankshaft. First, the

increased stroke increases the pumping pulse energy by about 18.5% based on a

crude back of the envelope formula. Second, the GTS crankshaft counterweights

are very poorly designed. They not only cause high bearing loads but also block

the crankcase gas flow with the addition of the center counterweights and the

large fan angles of the counterweights. Finally, at least some GTS pistons do

not have sensible oil drain provisions, leading to poor oil control on the bore

walls and significant blow by that may be impossible to resolve with an external

breather system. This combination leads to a situation in which crankcase is

pressurized by blow by, oil is ejected to the intake manifold, the ejected oil

will cause detonation, detonation will cause increased blow by, etc.

===

Reading the patent is illuminating. What they described in the patent was

implemented in the '87 S4.

The factory intent was to primarily vent from the filler neck to the valve cover

and then from the valve cover to the MAF elbow. For this to work, they must have

assumed that the oil filler neck always has a higher pressure than the valve

cover. We should verify that assumption. If the assumption is not true, then

there is trouble with the air flowing the wrong way in oil drain channels.

The connection from the oil filler neck to the MAF elbow Y was thought of as a

secondary, backup, "safety" venting channel. For that to work, all that was

needed the static pressure at the MAF elbow being lower than at oil filler neck.

It is not necessary for the valve covers to have a lower pressure than the oil

filler neck.

Inexplicably, in the GTS model they eliminated the path that was described as

the main breather channel in the patent. They connected the passenger valve

cover to the driver valve cover. I can only think of one logical explanation of

why they did this. They intended the crankcase to vent to the valve covers thru

the head oil drains. The two valve covers were connected, because under lateral

g-forces one side of oil drains, but not both, could be blocked by oil. They

counted on at least some of the eight large oil drains to flow enough blowby gas

to the valve covers that they could then be routed to the passenger side and

then to the MAF elbow. The safety vent directly from the oil filler neck to the

MAF elbow remains there.

What could have motivated the change? The components aren't any cheaper in the

GTS version, in fact there's one more metal valve cover elbow fitting needed

which is expensive. They must have thought that the connection that they

eliminated, from the oil filler neck to the passenger side valve cover was

counterproductive. The only way that I can think of it being counterproductive

is if they came to the conclusion that air was flowing in the wrong direction

from the front of the passenger side valve cover to the oil filler neck and that

air being replaced by air flowing up the drain channel. Why else would they

eliminated that connection?

This leads to the interesting question why would air flow from the valve cover

to the oil filler neck? The only reasons I can come up with are the following:

either it's the piston pumping pulses doing something unexpected, or the

crankshaft rotation pulling a low pressure to the oil filler neck at high rpms.

Anyone else with any hypotheses why they moved away from the scheme of the

patent?

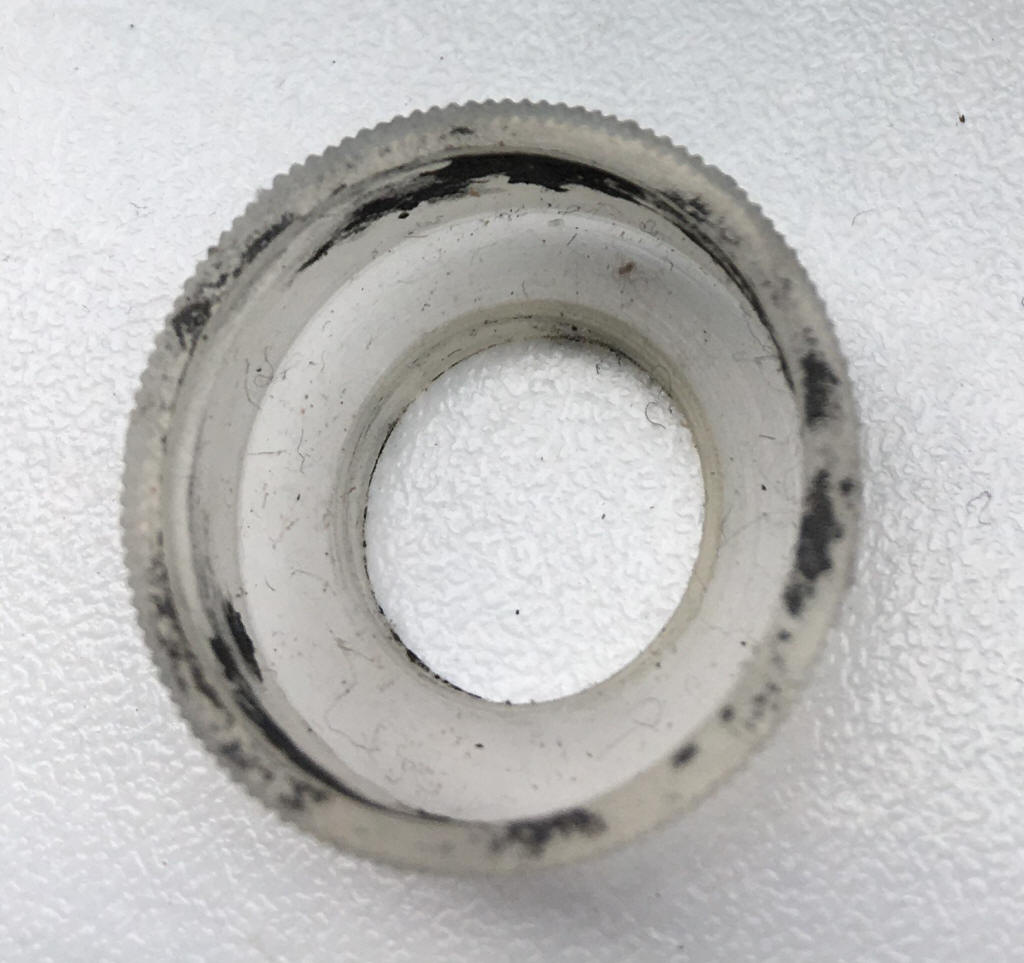

Also, what's up with the check valve in the y? Here's Mike Schmidt writing about

the system:

Mike

Schmidt has figured out how the 928 S4 crankcase breather is supposed to perform

it's functions and offers this explanation

Quote:

The air can't go through the smaller diameter angle cut section of the plastic

"Y" piece because of the check valve.

Mike mentions that there' a check valve in the y-piece. The patent doesn't

mention it and neither of the two y-pieces I have have a check valve. Unless the

check valve is the 100 millibar valve they mention. That's it I am guessing. 100

millibars is a lot, though, like 1.5 psi. It really is only a safety valve then

if calibrated as the patent prescribes, and the filler neck to will only vent

directly to the filler neck when the situation is pretty dire in terms of

excessive crankcase pressure.

Edit: mystery solved, my spare 87 engine has a check valve in the oil filler

neck. Haven't measured the cracking pressure, though.

Ok, so the mystery deepens. The factory seems to have eliminated the check valve

from the GTS oil filler neck when they moved the port higher. Is this true? If

it is true then, isn't the throttle closed breather flush function simply going

to draw the air from MAF elbow and the crankcase doesn't get flushed with fresh

air? I think I understand the factory's intent with the S4 breather system, but

now the GTS system doesn't look very well though out to me. Maybe they thought

that by connecting the valve covers they would get enough crank rotation induced

flow in the heads and crankcase, and wanted to eliminate the check valve simply

to increase the flow capacity of the system?

taken from updates by "ptuomov"

===

If there is no check valve in the oil filler neck, like with the GTS, what's

to prevent the closed throttle circuit from drawing the air directly from the

hose that connects the oil filler neck and the MAF elbow? As far as I see

nothing. If so, there's not fresh air circulating in the crankcase, removing

water and fuel vapors.

The early GTS, based on hearsay, has a 6mm restrictor in the valve cover elbow

and a 5mm restrictor in the oil filler neck. That arrangement flows about the

same as the S4 system at high crankcase pressures, assuming that the 5mm orifice

and the safety check valve flow about the same.

According to hearsay, some GTS engines have no 6mm restrictor in the valve cover

elbow. This will increase the flow capacity of the system, but now the gas

velocity in the air-oil separator tube in the valve cover may become too high

and the elbow will spew out oil. It would in my opinion be a preferable solution

to increasing flow capacity to add an additional breather to the other side and

retain the 6 mm restrictor on both sides.

ptumov

=====Interesting discussion about this: https://rennlist.com/forums/928-forum/776080-how-to-do-the-boosted-car-crankcase-breathing-right-7.html

and more here: https://rennlist.com/forums/928-forum/560928-twin-turbo-928-fixed-and-back-out-there-terrorizing-the-streets-77.html#post13127650