For a while I have felt there was some kind of problem on the rear axle,a

kind of snatching feeling as though the diff was fully locked. During today's

event the rear axle was making all kinds of strange noises but I did not see or

notice the PSD lamp coming on. Upon completion of my run the Porsche chaps

visiting from Europe, although pleased to see the 928 performing well, commented

on how they felt my diff as locked, possibly all the time.

This made me wonder what may be happening- my first thought was whether the PSD

slave cylinder was sticking in the locked position. tomorrow I will jack the car

up and try rotating one wheel- as I am aware the other wheel should turn in the

other direction. If it turns in the same direction that would suggest lock up.

Given I was not seeing the PSD lam illuminating I am assuming that the issue is

not being caused by hydraulic pressure being falsely applied.

Much appreciate thoughts/suggestions regarding similar experiences.

__________________

Fred R

====

Hi Fred , we have seen several 928S4/GT/GTS ( 1990-1995 year models ) where the

PSD has leaked the PSD fluid ( brake fluid ) into the diff itself , this "brake

fluid " will cause issues with the LSD friction plates , the early " minor "

issues is a shuddering of the LSD , if its attended to quickly ( Diff apart )

and cleaning out what looks like a black goo in-between the plates ( that's the

remains of the old brake fluid ) and once'd cleaned and reassembled with a new

PSD slave cylinder and the important 928 332 051 05 protective boot ( this helps

to stop the PSD fluid getting into the diff ) it will be fine

Now onto the ones that we worked on where the owner of the said 928 ( 1990-1995

year models ) where the PSD / brake fluid was allowed to stay in the diff for a

longer period of time , now this is where it gets interesting , the PSD / brake

fluid effects the friction plates and the friction material de-laminates and the

LSD "friction pack " literally swells up and the diff locks up & with

de-laminated friction plates , well its all too late & it will need new plates (

if you can get them ? ) or a 2nd hand 928S4/GT/GTS PSD diff center that has not

suffered that fate

Note } You may not have what I described above, it may be something else ? , but

if you do have what i described , then , get it apart as soon as possible

Note 2 } the 928 332 051 05 boot I mentioned , when old , there will be little

remaining of the old one , once you see a new one you will know what I mean (

its not just a simple boot )

Regards

Bruce & Sean Buchanan

Buchanan Automotive

====

So I just jacked the car up and put it on my home brew liftbars and upon

rotating driver side wheel forwards the other wheel revolves in the same

direction so diff system definitely screwed at the moment.

I changed the dif oil a couple of years ago with a high spec Mobil diff oil but

it was not one formulated for PSD. There was nothing I could find in the

documentation I have to specify any other PSD specific diff lube but we had some

discussion about this. Whether this is a relevant factor opinions appreciated.

If hydraulic fluid has migrated into the diff then I would expect to see a level

issue in the reservoir although how much has to leak to cause an issue remains

to be seen. One also wonders if the rear seal on the tranny has failed allowing

ATF to get into the diff but there is seemingly no "pressure differential"

driver between the two cavities?

The only other test I can think of at the moment is to open the slave cylinder

bleed nipple to test for hydraulic lock up however unlikely that may seem.

_________________

Fred R

=====

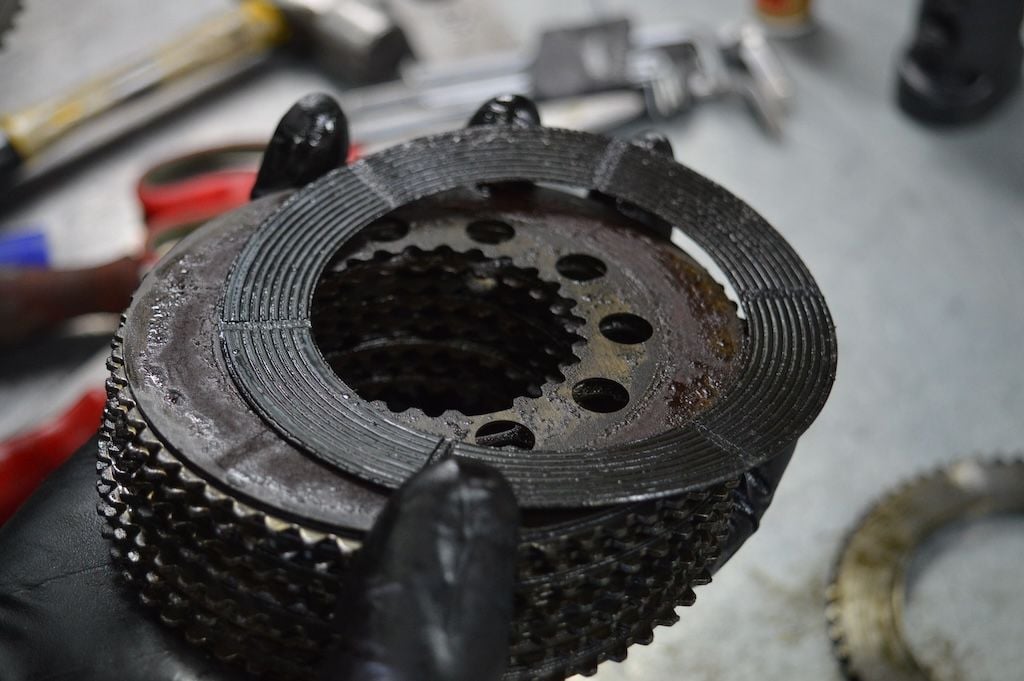

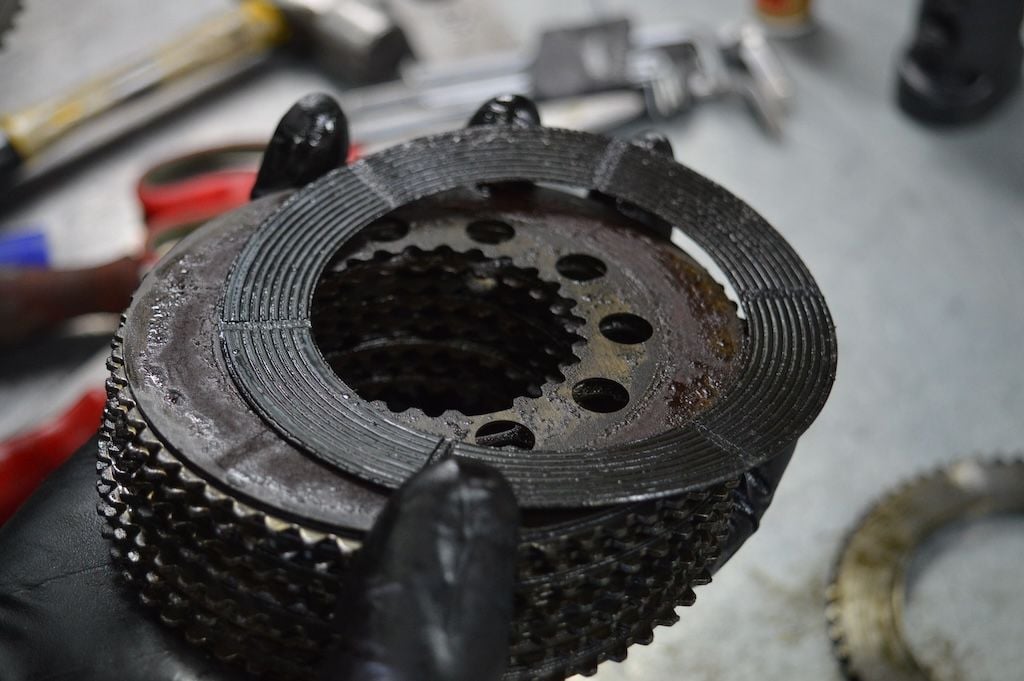

Unfortunately there is no adjuster to release the tension of the clutch packs

when they swell per se as once they go that way they increase in size quite

considerably and are have too much tension in the clutch basket area. We had one

recently that had brake fluid entering via the PSD slave for some time and you

can see by the pictures below that it also caused quite a bit of corrosion

inside the diff housing, It was quite difficult to get the differential side

bearing carriers off. Preload on a correctly measured clutch pack in set via the

pressure plate finger housing (Pic 5)

On the differential below we were able to remove one friction material and one

steel plate so that the car was still operational and without the lockup noise

(with the PSD disconnected) while we waited for a good 2nd hand PSD unit to

arrive.

You can see in pic 1 and 2, the delimitation of the friction material. pic 3 and

4 is the corrosion. Pic 6 was a second diff that we used good plates from to

make a working unit

Regards

Sean

====

Hi Sean,

Much appreciate the photos. Today I released the slave cylinder bleed nipple and

nothing came out so "trapped pressure" goes out of the window. I suppose it is

possible that the cylinder is jammed in the locked position but it is so

cluttered in that location I do not fancy trying to test for thrust due to

seized piston at the moment.

On a more amusing note I removed the slave cylinder from my spare transaxle unit

and as the thing came off the bolts there was a pile of white powder! I removed

the circlip and there was no sign whatsoever of the aluminum piston- it had

completely corroded away- why I know not- it is not as though it was exposed to

brake fluid. On the positive side the inner walls of the body were spotless and

it should be viable if a new piston is available!

I then took a look at the PSD unit and the fluid level was just above the

minimum mark. I cannot remember where the level was after I changed it out-

probably at the full mark line so possible I have some fugitive brake fluid but

the maximum it can be would not amount to much at all- circa 20cm3 there or

thereabouts I suspect. I was impressed by the bellows and the escape path for

any brake fluid that escapes the piston.

To do any meaningful work in-situ on the diff I concluded that the exhaust, the

half shafts and the fuel tank need to come out- tasks I have completed

previously albeit the fuel tank is nearly full at the moment!

For now I will be departing for the UK so time to study the WSM section 39

covering the PSD system. When I return I intend to disassemble the diff on the

spare unit to harvest clutch parts and get a feel for working on it. It does not

look too complicated as long as one does not screw up the shim packs.

====

A brief update of my findings to date as of Wednesday:

1. I opened the slave vale bleed nipple just in case there was trapped pressure

but nothing was found. So unless the slave cylinder piston has jammed/seized

then I am inclined to think the scenario described by Bruce is in play.

2. I removed the protective shield in the rear wheel well to expose the PSD

unit. The level was at low point of the acceptable range. I cannot remember

where the level was when I last flushed the hydraulics but knowing my modus

operandi it was probably at the maximum level so I am assuming a small amount of

fluid loss may have taken place that does not amount to an awful lot- whether is

has leaked into the diff housing I have no idea at the moment- needs further

investigation when I return back home. I did not see any signs of brake fluid

emanating from the pinhole that vents the chamber encapsulated by the bellows

for whatever that may be worth.

3. I removed the diff cover from my spare transaxle unit and everything in there

that I could see looked to be in excellent condition. Hopefully the clutch plate

set will be in stellar condition for potential re-deployment- but...?

4. I need to bone up on dismantling the unit once it is out of the diff housing.

Nice looking piece of kit I must say and that before considering it is 33 years

old. The clutch tensioning system is very simple even if the calibration

procedure is a bit "tricky". I understand clutch plates are NLA - doubtless

there will be facilities that can prepare such at a price if needs be.

5. Next step when i return will be to drop the exhaust and the half shaft to

create some working room and then to check what happens if the slave housing

bolts are loosened.

Fred

====

I returned home last week after spending 4 weeks in the dismal UK climate

with my daughters. Today I decided to take a look at the above problem once more

and my next step is to release the slave cylinder from its mount to see if that

shows any signs of unlocking the diff. A month ago I opened the bleed valve to

see if there was any trapped pressure but not the case.

Once one has access to the bolts on the slave cylinder getting them undone is

simple enough but it seemed to me that the passenger side exhaust needs to come

off followed by the half shaft to enable appropriate access. Before I do that I

will take another look to see if I can possibly avoid such. However i am now

planning for the worst case. Just wondered what others have found if and when

trying to get the PSD slave undone.

Whilst in the UK I picked up a neat looking electric impact wrench supposedly

rated for about 650 ft lbs. Not sure I believe that but am open minded. It had

the wheels nuts off in a flash and given that is its prime role was pleased with

the performance. With the wheel removed I wondered if it might get the stub axle

nut that is torqued to 340 ftlbs or whatever. I let it hammer away for about 10

seconds but no signs of movement. This made me wonder if and when attempting

something like this how long should it take to release the thing- any thoughts?

Fred

====

Removing the fuel tank makes access easier... Phil

====

Hi Phil,

It sure does and will be absolutely necessary if i have to remove the clutch

pack as seems likely.

The trouble is both my other vehicles have full tanks of fuel at the moment and

so does the 928 that has about 80 litres on board at the moment given I filled

it just before this problem became apparent. Even my 20 litre jerry can is full

just to add insult to injury.

Fred

====

Just had another look at the task at hand and maybe I can undo the half shaft bolts and lower it out of the way with the stub axle still connected- thoughts?

My query was aimed at resolving whether with the flange bolts undone and the

shaft lowered [but still retained], it would generate enough access to get at

the slave cylinder. Either way I will probably remove the half shaft completely,

drain the fuel tank and remove that completely. Then I can drain the diff and

remove the cover plate to take a look at the insides and see if there are any

signs of clutch plate material fragments.

Was not feeling too clever yesterday so read up section D39 of the WSM in more

detail. The amount of lock up applied is controlled by the applied pressure in

the slave cylinder and it seems this is achieved by applying a specific number

of release pulses on the hydraulic unit to achieve the computed degree of lock

up. The break torque is plotted as a function of hydraulic pressure. The test

procedure seemingly requires a special kind of torque wrench and when with the

hand brake applied, the left hand hub starts to move as the wrench clicks that

defines the break away torque when they coincide.

If as I suspect the clutch pack has swelled [as Bruce defined earlier in the

thread], I should be able to "unlock" the diff if I release the pivot bolt used

for setting the system. Needless to say I will release this in increments of 1

full turn until I detect the unit slipping at the specified torque [less than 50

ft lbs]. If this proves to be the case then I will know for sure what I am

dealing with and if nothing else I can at least run the thing until I implement

a solution. I will also know how many turns are required to set it back to where

it current is. Anyone see a problem with this?

I also intend to remove the diff pack from my spare transaxle unit to get a feel

for the removal process. This should enable me to harvest a viable clutch pack

all being well given this unit had only covered some 120k km at the time I lost

my late 90S4. Seems there is some spec difference in the clutch pack deployed in

the GTS compared to that in the 90S4 - whether that is of any real world

significance remains to be seen. Porsche generally do not change things just for

the sake of it [or so I tend to think]!

Fred

====