Contributed by Eric Dzubehor, Oct. 24, 2004

Introduction

To lower costs, Eric converted his 1990 Range Rover to a more generic Bosch alternator used on a wide range of VW models. Details of his conversion are on the Bosch alternator conversion page. Below, he details the procedure he followed to rebuild his VW-derived Bosch 120 amp alternator. The procedure should be similar for other Bosch alternators found on Range Rovers.

Eric offers the following caveat about alternator rebuilding if you attempt this yourself:

"This worked for me, but that doesn't mean it will work for you.

Do this at your own risk! I will not be held liable for your own actions. If you hook-up a wrong wire, and burn your home or car down, that's your fault! If you feel you don't have the skills to do this, ask someone who does."

Voltage Regulator Details

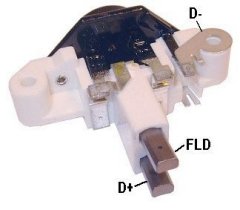

Voltage Regulator

VW part #: 028 903 803D (replaces many Bosch #s).

Transpo #: IB388

WAI #: 35-9108

Step By Step Rebuild Procedure

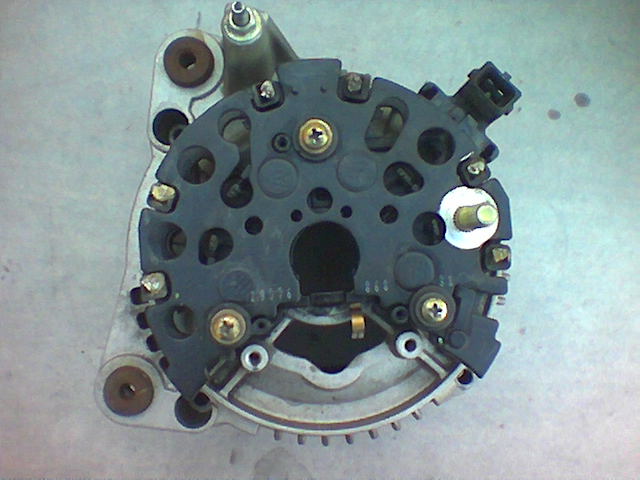

To replace a voltage regulator, remove the black cover (3 phillips screws, and disengage the 3 pry tabs on the side of the cover).

Carefully lift and remove the cover, set it aside.

You'll see that the voltage regulator is secured by 2 phillips screws.

Remove them and set aside, and carefully lift up the old regulator and place it someplace secure (if you will reuse it).

NOTE

Now would be a good time to replace or repack your bearings (details below). Also I would suggest you clean up the slip rings and remove any oxidation of the voltage regulator contacts (on the alternator case, and the rectifier assembly tab).

Use 600 fine grit wet or dry Silicon Carbide sandpaper on the slip rings, then wipe clean with a rag when finished. Use the same sandpaper to clean up any oxidation as noted above.

Carefully align the new voltage regulator, be careful not to damage the brushes.

Set the regulator in place and reinstall the 2 phillips screws. Give the alternator pulley a clock wise spin, check that the brushes are making proper contact with the slip rings.

NOTE

If your going to repack or replace the rear bearing, remove the 4 phillips bolt head screws located around the outer perimeter of the rear case. They are 8mm, you will need to use a socket and 1 closed end wrench (the wrench is needed due to the limited space as its under the W and D+ plug).

Remove the voltage regulator before attempting the following.

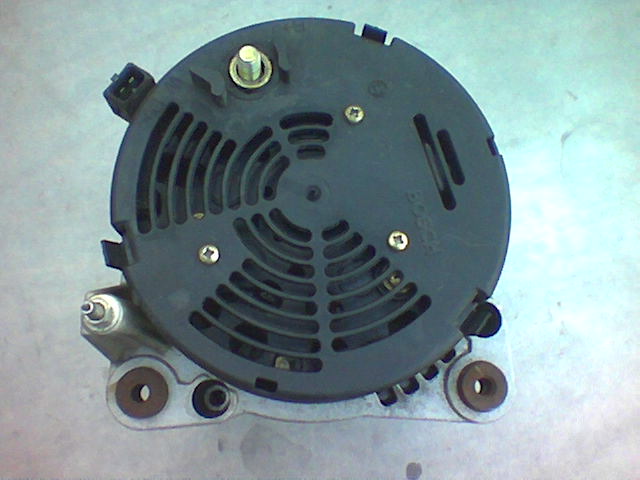

Using a flat head screwdriver, carefully pry the case at all four sides as shown in the pic. The two halves will come apart, some may be a bit stubborn.

The rotor will stay with the front pulley half, the stator will come off with the rear rectifier assembly.

Now depending on the age of your alternator, the rear bearing may not be worth saving. It may have a hardened seal and prying it off may damage it, rendering it useless. The only solution would be to replace it with a new one.

NOTE

Please take the time to repack the new bearing with synthetic grease. Failing to do so will result in premature failure of the bearing.

There just isn't enough grease in it from the factory.

Don't loose this bearing housing AKA the tolerance ring

If you suspect the front bearing needs attention, the pulley needs to be removed. The use of an impact gun makes quick work of this.

Not having one handy, your in for a lot of knuckle busting. I would advise to find a friend with an air compressor or take your alternator to friendly mechanic.

With the pulley off, you'll see 4 phillips screws, these secure the front bearing to the front case. You may need to use an impact screwdriver to remove these stubborn screws.

Pulley and screws removed.

Here is the thrust washer. Note that it is tapered on the inside, facing the bearing.

Before the bearing can be removed, the thrust washer must be removed first.

The following were removed:

Thrust washer, bearing and bearing retaining plate.

This picture shows the orientation of the parts.

Make sure the bearing retaining plate and the thrust washer are installed correctly.

The bearing plate threaded holes will face the rotor assembly.

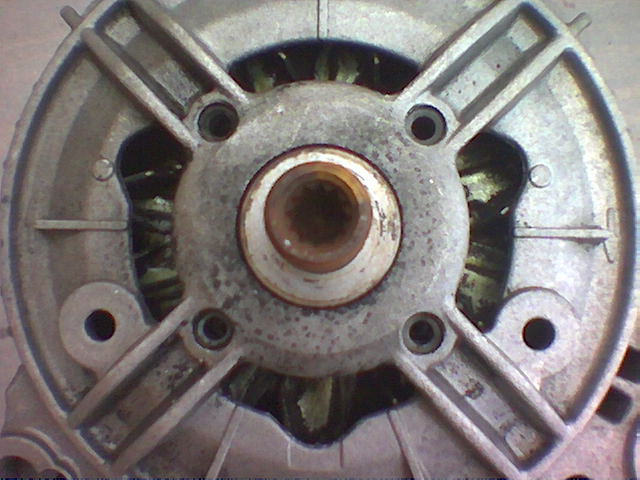

Rotor with slip rings.

Old Bearings

Rear-small: 6203 RS or 6203 2RS (rubber seal) 17mm ID x 40mm OD x 12mm W

Front-large: 6303 RS or 6303 2RS (rubber seal) 17mm ID x 47mm OD x 14mm W

Seals: Labyrinth closure system that keeps the dirt out and the grease in.

NOTE

Do Not use 6203 ZZ or 6303 ZZ bearings, these are metal shielded bearings, but are not sealed.

Grease will quickly fly out of it, and you'll have a noisy alternator in no time.

Notice the rear bearings inner lip seals are damaged, this is due to hardening.

Thank you Bosch for using cheap Chinese made bearings.

According to the Bosch web site, they use 100% new high quality bearings. Bosch web site.

Bearings come in many different varieties. The thing to keep in mind is cost and performance. The low end bearings are usually ABEC 1 rated.

ABEC stands for Annular Bearing Engineers' Committee. This committee works to determine the standards for bearings for the Anti-Friction Bearing Manufacturers Association (AFBMA).

The ABEC scale classifies different accuracy and tolerance ranges for bearings.

The higher the ABEC number the more precise the bearing specs are.

Just pick a name brand such as the following, and you can't go wrong. Most will have a Hi-temp, Hi-speed bearing.

BCA, FAG, KOYO, NTN, SKF, TIMKEN

NOTE

The Following is just some info on replacing your rectifier assembly

Remove the 3 phillips screws and set aside. Assuming you already removed your voltage regulator, de-solder the 6 terminals where the stator wires go. This is easier said than done, but having a 140 watt soldering gun and a solder sucker helps. You may need to use a tiny pick or jewelers screwdrivers to pry apart the rectifier assemblies solder terminals.