Well my maintenance work progresses and today I was ready to remove the

in-tank pump I have written about in an earlier thread. It is not long since I

removed it previously when I had a failure of the internal pipe and had to

solder new wires and fit new hose- about three years ago I suspect.

Many of our listers myself included know full well about the insert problem and

I figured that since it came out last time and was torqued to spec upon

insertion, it should come out OK today- well I got that one well and truly

wrong!

First of all I decided it would be best to remove the tank - took a look at the

WSM- nothing special about the job and set about it. Supported the underside of

the tank whilst removing the cradle, cut the tank vent and return hoses that I

planned to replace and removed the delivery line that routes under the tank.

Removed the spill collar and the fill port and then undid the top support bolt.

figured the tank should now come out - wrong!- it just seemed to be hung there-

what the heck! Scratched my head a bit had a coffee and took another look and

spotted the problem- there is a vent line from the top side of the main body

with a silly big hose that crosses tightly through a bulk head and then fastens

at the top of the fill neck [to act as a vent] via a tee fitting with the fuel

return line- the WSM mentioned nothing about this . The connection on the tank

body is inaccessible, fastened by a clip and not immediately visible- WTF? I

then had to wrestle the tank out and everything seemed to get in the way- had to

displace the passenger side mid exhaust section some but not too difficult.

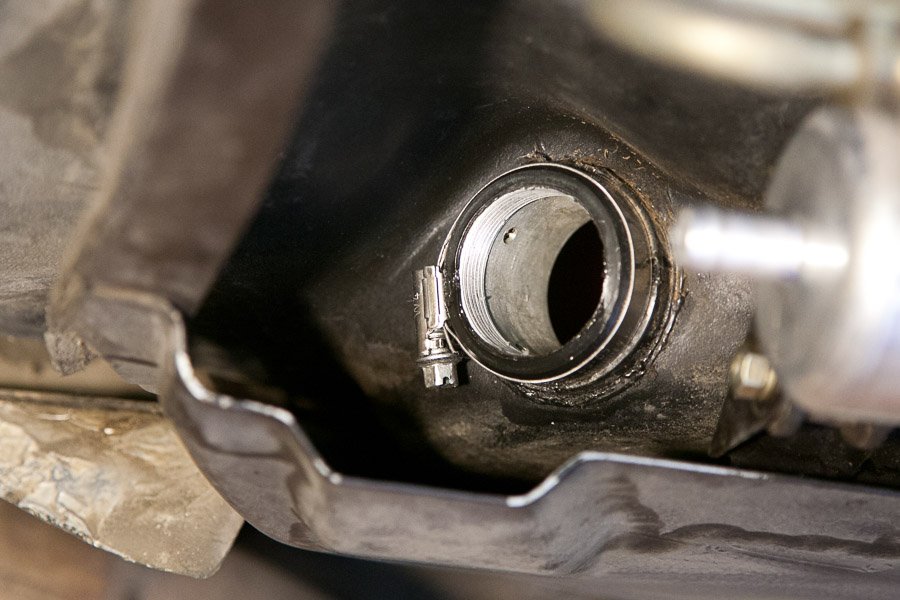

So with the tank out and on my work bench I then took a look at the thing and

the the first problem was how to undo the pump from the insert- I figured the

easy way would be to fit a jubilee clip around the collar as I probably should

have done earlier but will come to that a bit later. I cleaned off the 4 nubs

that stick out a bit but that was probably a waste of time as the clamp I had

was wider than the recess it sits over. Anyway to my delight the thing came

undone nigh on effortlessly. Tried to remove the pump once the flange was fully

unscrewed but it did not seem to want to come out so I undid the clamp and out

it came- cannot explain that one- maybe I was just a bit too tentative.

Upon inspection it was clear that the insert had been pulled out about 1mm or

so- see pic below.

Insert proud of the boss.

So my next line of thought was "what to do next"? As I started to think about

what happened an interesting thought sprung to mind-as I tried to remove the

thing the applied force must have pulled the sleeve into the sealing ring thus

lifting it to the point where it no longer sealed - I also noticed that after

the first drops of residual fuel appeared as I tried to undo it more fuel

leaked- this suggested to me that the seal entirely depends on the ability of

the pump to pull on the threads and seat on the outer ring of the tank boss.

Thus if the clamp enabled me to remove the pump maybe I could push the insert

back where it came from and if I did, maybe the external clamp holding the once

more correctly positioned insert will enable the seal to pull down on the boss

and seal it once more with no other modifications.

I measured the outer diameter of the insert and found that a 34mm socket had

more or less the same outer diameter- after careful placement of the socket and

a few blows with a rubber mallet the insert popped back. Even more

interestingly, it looks as though the boss has a slight overlap of the insert.

The pic below shows what it looked like after reseating the insert.

Insert pushed back in

So, considering the above and the fact that the sealing surface of the hub looks

pristine, I am now inclined to think that given it locked the insert to get the

pump out, maybe with a new seal and the jubilee clip fitted just maybe it will

seal once more.

Tomorrow I will test it but in the meanwhile any thoughts appreciated.

Now just kicking myself for not figuring this logic out earlier even though I

previously knew about the clamp- just figured that if it was degraded probably

better to find out - however, if the hydraulic seal only depends on the insert

being held tight then for sure everyone working on their tank should do this mod

immediately before touching whatever is fitted inside the boss - ironic that I

thought about such before going in and decided against it- lesson learnt on that

one!

__________________

Fred R

===

When my insert migrated, I pulled it out and whipped up some Marine JB Weld.

I coated the insert and pressed it back in place.

__________________

Kevin

===

Logical thing to do and on my list of possibilities but I am wondering if

anyone has thought about the issue laterally and simply tried to lock the thing

back in position but this time using the obvious clamping force applied when

externally clamped.

Logic tells me if I could release the in-tank pump normally after what happened

then maybe it will also permit the seal ring to work once more. It is a bit

counter intuitive but stranger things have happened.

__________________

Fred R

===

Fred at this point I would suggest you get some aviation fuel tank sealant

sealant..

pull the ring out , mark it first. Then put the sealant into the tank grid, then

install your insert then add on a proper size Norma clamp to hold the outer edge

of the tank tight against the insert.

https://www.145.aero/Flamemaster-CS-3204B1-2-AMS-S-8802B1-2-Sealant-p/cs3204b1-2.htm

MrMerlin

===

Or use this solution: https://928srus.com/products/fuel-tank-repair-sleeve-boss-all-928-fuel-tanks-78-to-95

Roger

===

Thread:

https://rennlist.com/forums/928-forum/831473-fuel-strainer-assembly-loose-from-tank-928-a.html#post11611596

The seal is on the outer lip as noted, JB weld or whatever might help

mechanically but not needed for sealing.

The insert wants to go in from the inside, because the sealing surface has a small lip-- it will pull out, but it is very hard to push it back in. So I removed the tank-sender and sent the insert down that hole on a piece of wire as a guide.

Here is the special tool for pulling it in place, from the inside (made from

1/2" plastic electrical conduit IIRC) and a simple slide hammer to pull it in.

__________________

Jim & Sue Corenman