Porsche pull-down procedure, if the car is raised before the alignment.

Obtain actual vehicle height as follows:

- After the vehicle has been raised, starting at the influenced vehicle

height, pull the front axle down by 60 - 70 mm and hold for 1 minute. Use

special tool 10 - 222 A for this. Keep to the specified time.

- After releasing the vehicle, bounce the front and rear axles - approx. 25

mm - a few times.

(WSM 44-2 - Printed in Germany - XXI,

1989)

[10-222 A is an engine lift bar

spanning the lift rack and pulling down on the swaybar or the front transport

lugs]

Bill Ball

====

OK, just a bit of my primitive understanding of caster setting to clear up which

way to adjust the eccentric, the question I asked above.

As Jim indicated, we have positive caster, wherein the upper balljoint is

positioned behind the plane of the lower balljoint as shown here. Positive

caster provides straight-line stability and self-centering of the steering wheel

at the expense of some extra steering effort.

The spec for caster in the 928 is 4° +1 (so, max 5). A common observation is

that on many cars it is difficult to get caster down to the 4° spec. So, a

common solution is to set caster to the lowest value available common to both

sides. Make sure both sides are as close as possible to each other to prevent

pulling to one side. So, if one side will go down to 3.5° but the other will

only go down to 4.8°, set them both at 4.8°. Caster is measured indirectly by

calculating from camber at +20 and -20° turn-in, as described in Captain Earl's

guide and Jim M's detailed post above.

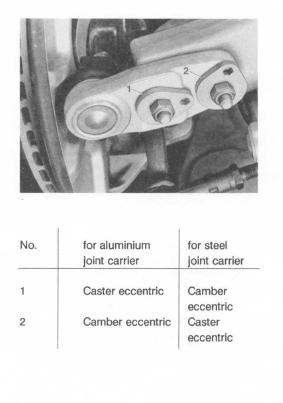

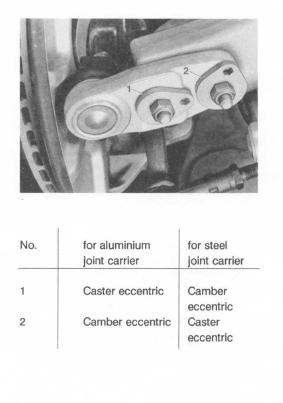

The caster adjuster in the inner (closer to the car centerline) of the 2

eccentrics on the lower ball joint carrier (unless you have an OB that happens

to still have the recalled aluminum balljoint carriers), as shown here:

To get caster to its minimum, you would turn that eccentric so that the lower

balljoint moves as far rearward as possible. Note that changing caster will

affect toe, but not vice versa. So, if you make an adjustment to caster, go back

and redo toe.

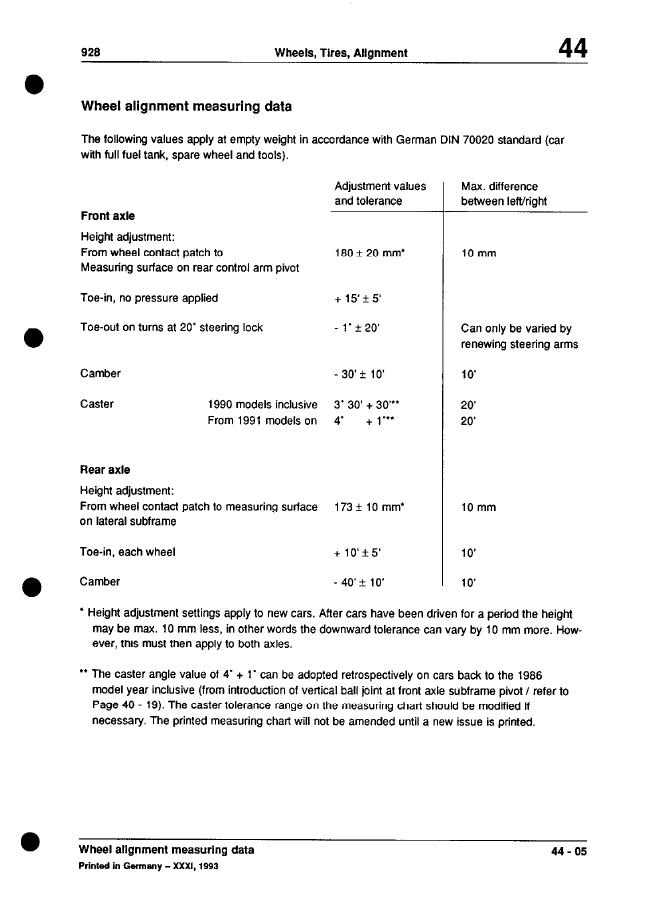

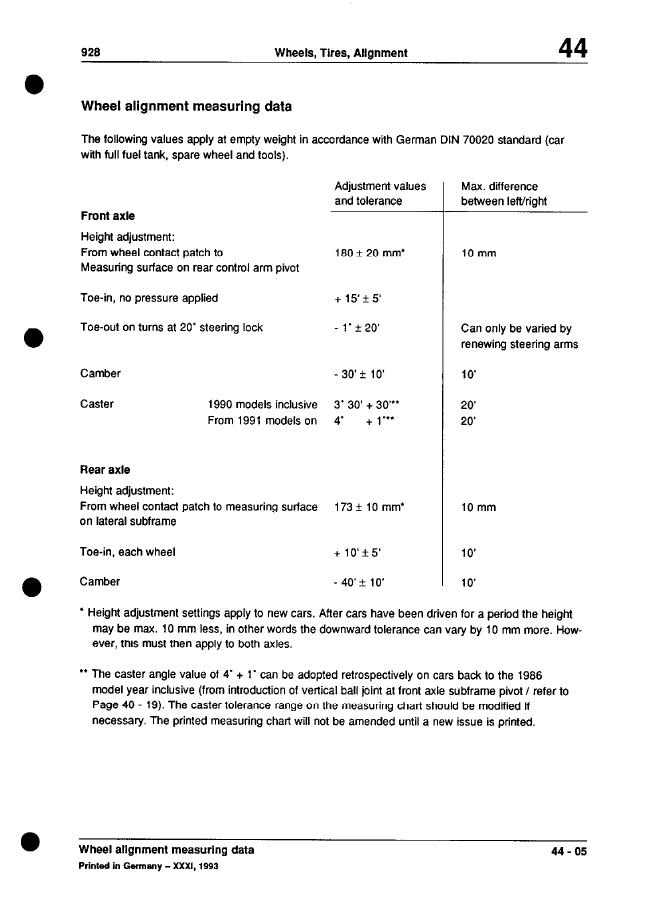

Since this is a master thread, here are the standard alignment specs from the

WSM. You should align as closely as possible to the exact center spec if there

is a range and minimize side-to-side variations. That is not to say there might

not be special settings that differ from this, such as toe out for quicker

turn-in on the track, but it is very rare that these are desirable.

Bill Ball

====

I agree with the midrange recommendation where the spec shows a +/- range. For

caster, they give a target number and suggest a + variation only from that

target. FWIW, a larger amount of caster makes the car a little more sensitive to

road camber, but seems to reduce tramlining some, especially when combined with

correct and even camber adjustments.

The specs that alignment techs use seem to allow side-to-side variation between

the wheels, and that can easily lead to pull to one side or uneven tire wear. To

keep the car going straight and to minimize tire wear, it's very important to

have the right and left sides identical. For example, the WSM camber settings

would seem to allow one wheel to be at -20' and the other at -40' (one-third of

a degree negative on one side, two-thirds of a degree negative on the other.) To

get the car to track perfectly with the steering centered would require an

offsetting difference in caster; that would cause problems at steering angles

other than centered though. The conclusion is that you can adjust the wheels

within the factory tolerances, so long as they are both the same.

Dr Bob

=====

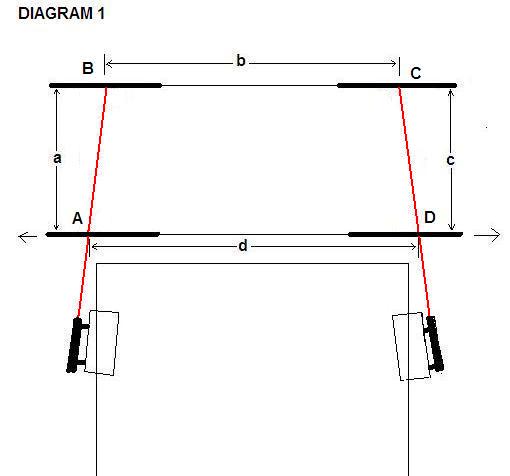

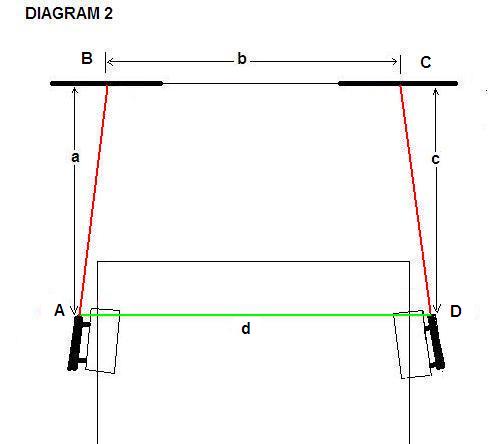

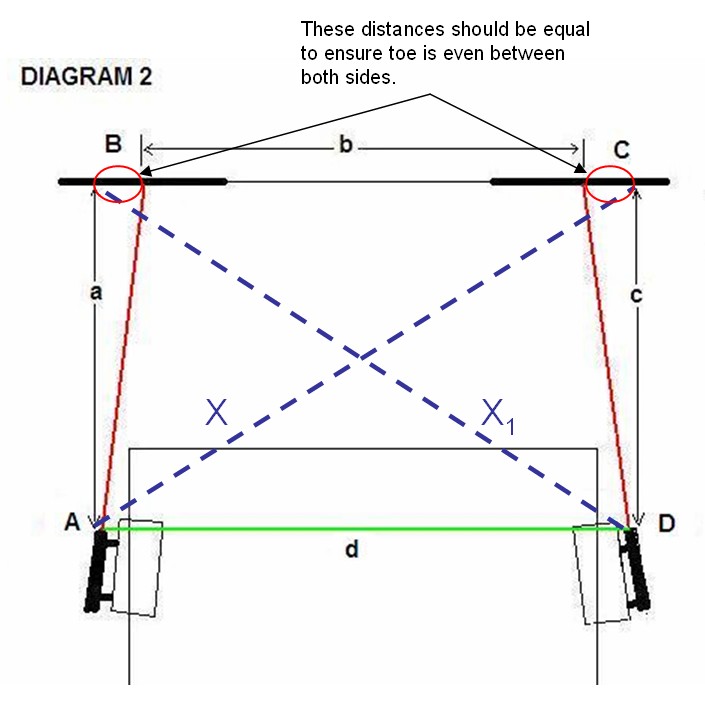

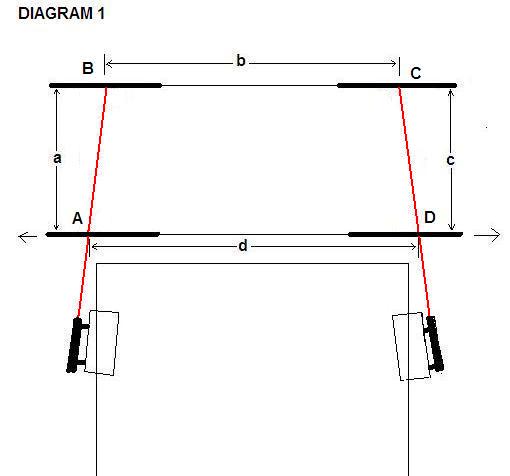

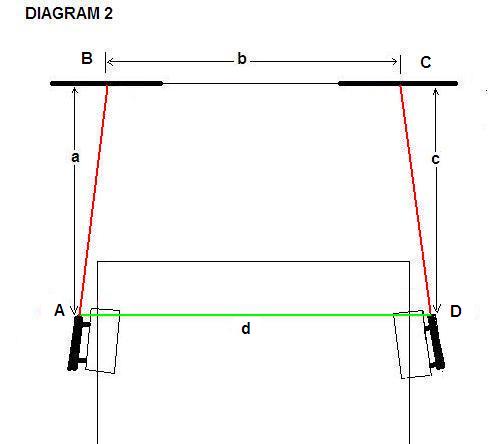

Here's a schematic diagram showing the lasers mounted on the front rims shooting

forward at two pairs of targets. The near targets are moved out of the way to

shoot the far targets. You measure the distance between the right and left dots

on the rear and the front target pairs. If you are toed-in, the laser dots on

far targets should be closer than on the rear targets. Diagram 2 shows dr. bobs

method.

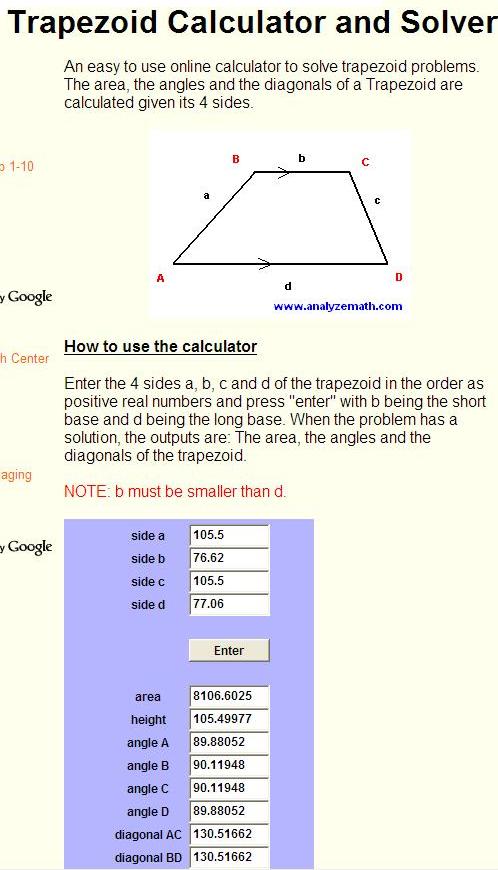

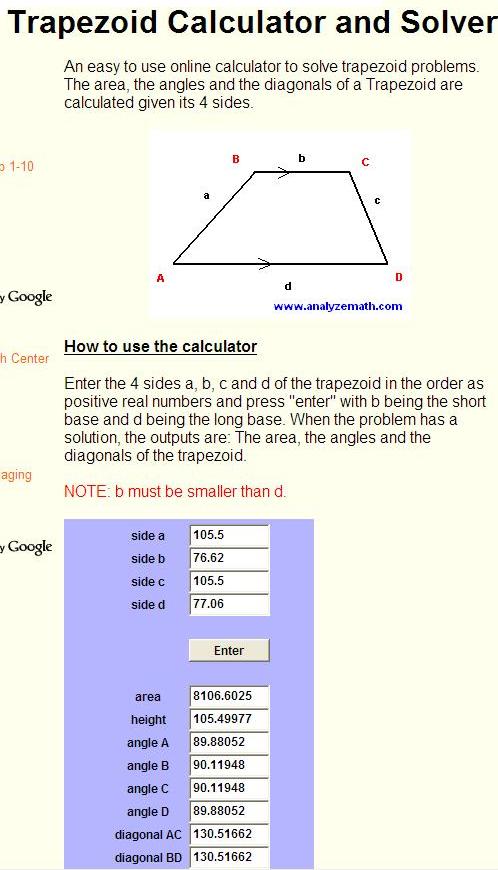

You can plop the numbers into this on-line trapezoid calculator.

https://www.analyzemath.com/Geometry_calculators/trapezoid_calculator.html

I've labeled the diagrams above to correspond to the on-line calculator. Here is

a screen capture with some hypothetical numbers that happen to hit the spec.

Note that I theoretically introduce a small error by measuring the distance

between the far and near target boards (sides a and c of the trapezoid)

perpendicularly rather than precisely from dot to dot. You could not measure a

difference between those two dimensions if you used a micrometer. It's just much

easier this way and the error is below miniscule (less than 0.001º).

The adjustment itself is pretty simple.

- Roll the car up onto the turntables (and board for rear tires) or slip plates.

If you have neither, you will have to roll the car after each adjustment.

- Pull the lock pins on the turntables.

- Take your initial measurements.

- If adjustment is needed, loosen the 22mm lock nuts on the tie-rod outer ends,

near the ball-joint, counter-holding the tie-rod adjustment flat with a 15mm

wrench.

- To move toe from positive to more negative, the rear of the front wheel must

move outward. So, turn the tie-rod tube by the adjustment flat so as to expose

more threads and lengthen the arm. From behind the tie-rod, this would be DOWN

on the driver (left side) and UP on the passenger (right side). Be very careful

not to lose your bearings and turn the wrong direction.

The adjustment is pretty sensitive. If you are way off, as with the two cars I

mentioned, a full turn may be a good start. But after that, 1/4 then then 1/8

and 1/16 will be needed to get the toe on the money.

This is a simple approach that ignores some fine points, such as the effect of

driver load. You can account for those by weighting the front seat. For some

driving situations, you may not want factory spec toe-in, but that is an

exception.

Toe has the most profound affect on driveability, handling and tire wear of any

of the alignment adjustments. As was the case with the two cars, it is OFTEN way

out of spec due to improper previous alignments, from raising the car prior to

alignment. Make sure the suspension is settled and do any ride height adjustment

days before adjusting toe. If need be, apply the WSM procedure for drawing down

the front suspension, as mentioned in the first post in this thread. although

it's best to just avoid it.

__________________

Bill

======

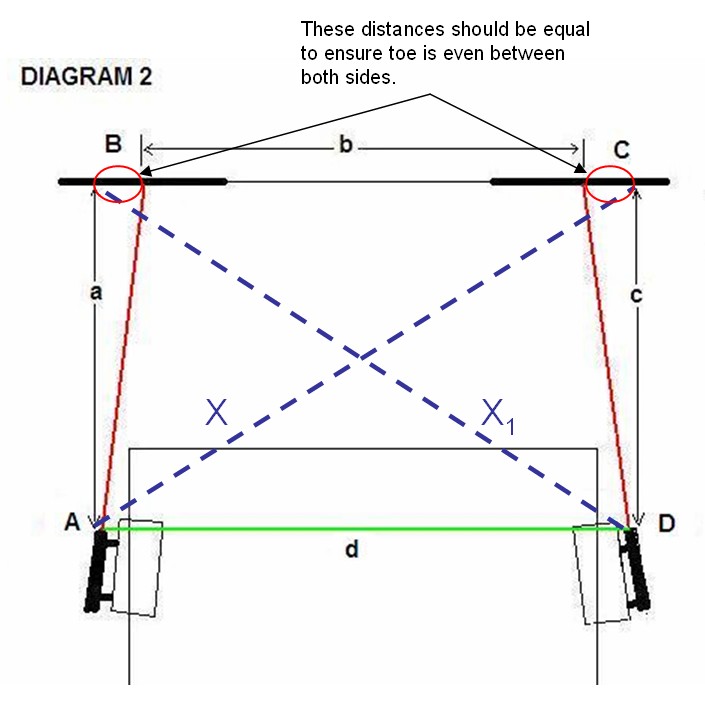

Using Bill's Diagram 2:

You would measure from point A to point C to come up with distance X. You then

compare this to distance D-B or as I call it X1. If X = X1, then you've got 90*

angles at ABCD.

Then to make sure you have equal toe on each side you would center distance

"little b" between points B and C.

Andrew Olson

===

Let's start off with the zero toe

idea. The reason that toe-in is specified is so that the wheels will be

perfectly straight when all the wear and play in the front suspension and

steering is preloaded while actually driving. If you have rigid pivots,

non-deforming bushings and perfectly tight ball joints and tie rods, zero might

be an OK static setting. You decide.

On to the geometry--

If the rack is centered (with the centering bolt is most desirable) and/or the

steering wheel is centered, a "toe in" on one side and an equal "toe out" on the

other side will make the car go straight down the road with the steering wheel

not centered.

The method that I shared early in the process uses a pre-calculated trapezoid to

help you set toe in. With your targets 84" apart, each 5 mins of toe is 1/8"

difference in width between the beams. For instance, I measured 30" forward from

the center of each wheel, and put a tape mark on the floor. Measured out 84"

from there, and put another mark on the floor in front of each front wheel. So

now there are marks at 30" from wheel center and 114" from wheel center, in

front of each front wheel. 4 Masking-tape tabs, in a rectangle, on the floor in

front of the car.

Now turn the lasers on facing directly forward (level, not down at the

ground...), and make a mark on each tape directly below where the beam passes

overthe tape. I used a carpenter's square, but you can easily use a plumb bob or

whatever you want, just so the mark on the tape is directly below the beam. Now

you have four marks. Measure the distance between the marks 30" away, and

between the marks 114" away. When you have the toe set correctly, the marks at

114" out will be 3/8" closer together than the marks on the 30" tape tabs.

That's for the spec 15 minutes (one quarter of one degree) of toe-in. If you

really want to start off with zero toe-in, the inner and outer measurements

would be identical.

If your steering wheel is straight ahead now when driving on a road that has no

camber/tilt to it, you can be fairly comfortable making exactly the same

adjustments to both tie rods as you get your toe where you want it. Borrowing a

little from the Earl Gillstrom bible, you can then turn the lasers towards the

rear of the car, and verify that the beams are equal distances from the centers

of the rear wheels on both sides. This assures you that the front wheels are in

fact equally adjusted and the front of the car will track with the axis of the

car going down the road. If they two distances are close but different, figure

out the average of the two distances there, and adjust the two tie-rods until

both distances match the average number you came up with. RECORD THAT NUMBER!!

If you can use the same fixture to check toe in the future, all you'll need to

do is verify that the beam distance at the rear wheels meets your recorded

average number, and your toe will be exactly the same every time.

I had a great phone conversation with Earl Gillstrom a while back, an finally

had a few minutes at home to implement his recommendations. The Biggest Change

is to the caster adjustments. Previously I had recommended that one should max

the caster adjustment, while Earl recommends that you start from the minimum

setting on both sides. I did a little research in the WSM, looking at the

pictures actually, and saw that the eccentric adjustment is not lined up with

the 'tab' that has the hex hole in it. The eccentric is 135 degrees away from

the tab. So my previous adjustment that seemed to work OK was really about

mid-ranged.

Yesterday's activity was to crawl under and adjust the caster to Earl's

recommendation for minimum. This means that the adjustment tab on the little cam

is towards the rear of the bolt 45 degrees towards the left side of the car. If

the car is pointing north, the tab will be pointing south-west if that helps.

Adjusting caster of course requires toe-in to be readjusted. I was a little

surprised to see that it was toe-out by 20 minutes after just that caster

adjustment. Using the laser fixtures it was very easy to get the toe back where

it's supposed to be. A short test drive suggests that the car is a lot less

sensitive to road camber (a Good Thing), but it still need just a very slight

adjustment to get it to track dead neutral. Just a little bit of caster adjust

on the left front will do that, along with another toe-in setting afterwards.

I may get over to the metal store this weekend for materials for laser fixtures

for those who have expressed interest. I did notice that the local Harber

Freight stores are no longer stocking the laser levels, so I may need to get the

store manager to order half a dozen for me. If it's not one thing it's another!

Dr Bob.

====