The reverse (B3) clutches in the GTS models are prone to wear, long before

the rest of the clutches/bands in the transmissions are worn out. This occurs

anywhere from 60,000 miles onward, depending on how much reverse was used during

the life of the car.

I've always assumed that Porsche/Mercedes used a softer clutch material, in the

GTS models) to soften the shift into reverse. (When these transmissions are

rebuilt with the latest version of clutches, they shift harder into reverse.)

The wear on the reverse clutches is a cumulative process and imminent failure

can be detected ahead of the failure by the vehicle taking several seconds for

reverse to engage once the vehicle is shifted into reverse. Sometimes, slippage

in reverse will occur, just before complete failure.

The complete failure can be manifested in two distinctly different ways, which

differ only by the way the transmission was originally assembled.

1. The most common failure:

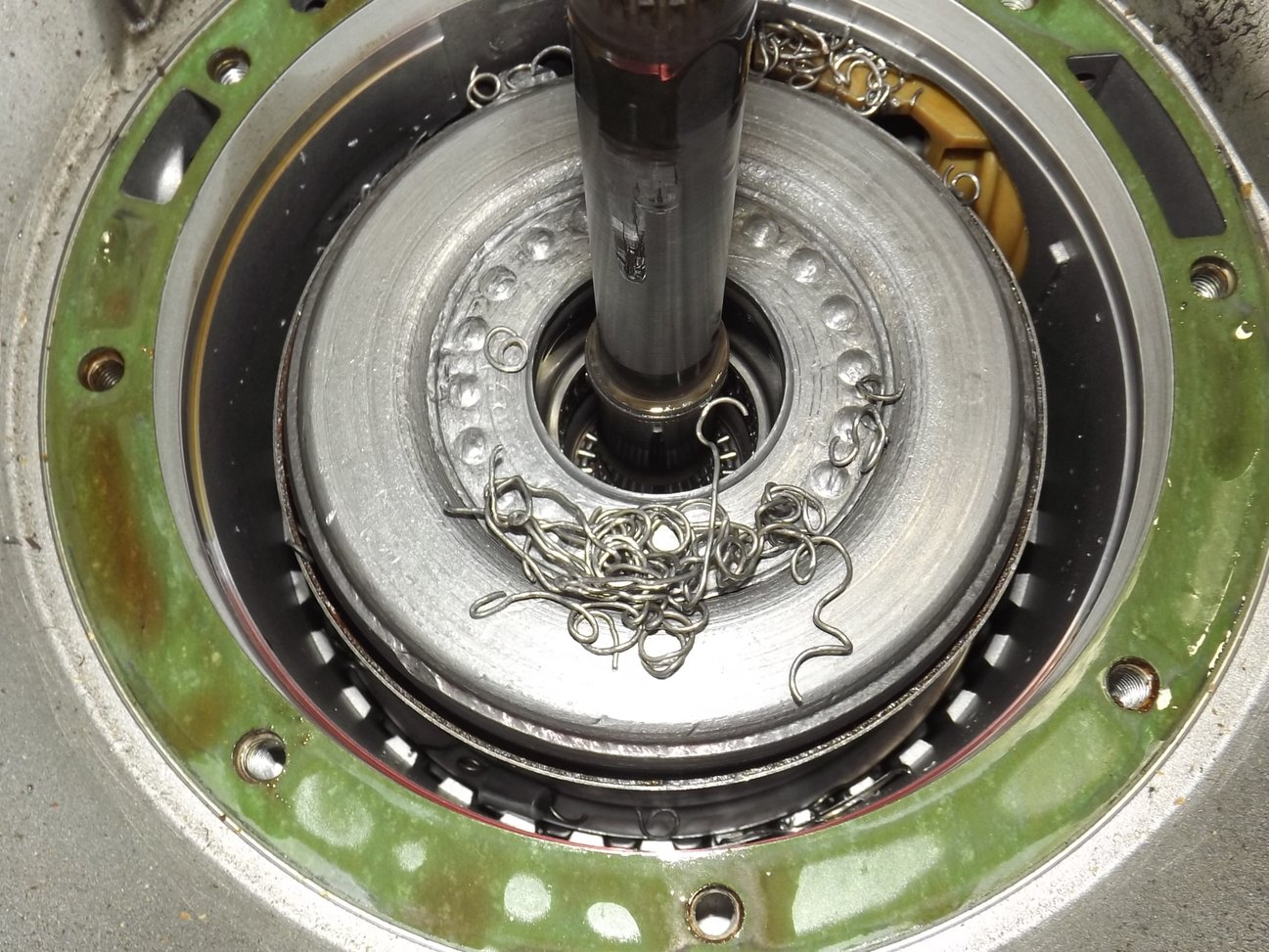

B3 piston travels towards the clutches with hydraulic pressure and is returned

with 20 small springs which are held captive by a retainer and a round clip that

fits onto the front oil pump support assembly.

Once the clutches are worn to a certain point, the piston return springs go into

"coil bind" and can no longer be compressed. The hydraulic force pushing on the

B3 piston is very high and those springs, which can no longer compress any

further, will not stop the pressure. The retainer for the springs is "blown"

over the round retaining ring. B3 piston keeps pushing until it blows past the

sealing limit of its seals. There is no longer any hydraulic force, as the fluid

simply flows uncontrolled past the seals/pistons.

Of course, the transmission is still spinning internally and the B3 piston, the

retainer, and the springs crash into the back of B1 drum, destroying all the

pieces, instantly. The front oil pump support and B1 drum is frequently

destroyed by the shrapnel.

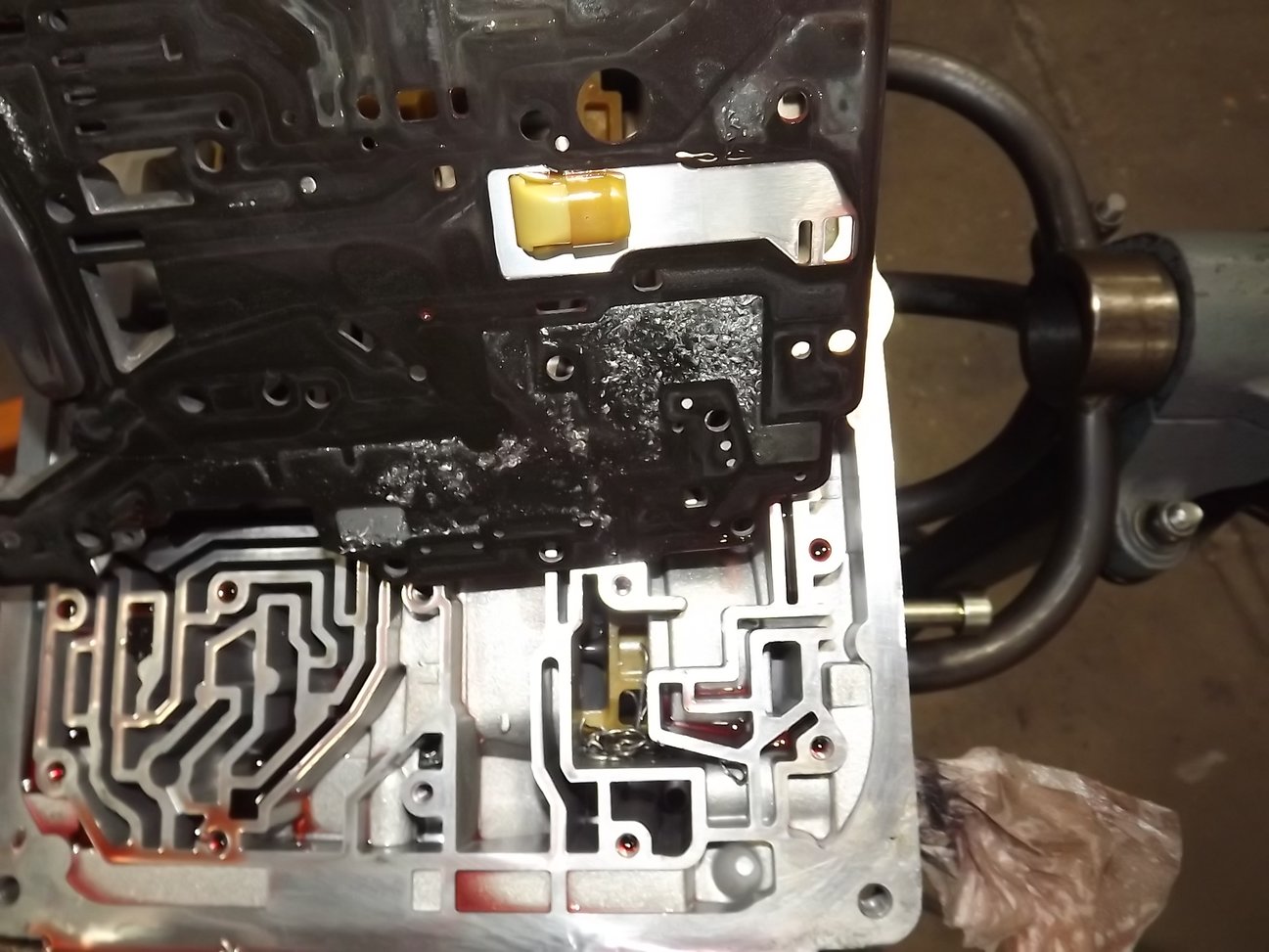

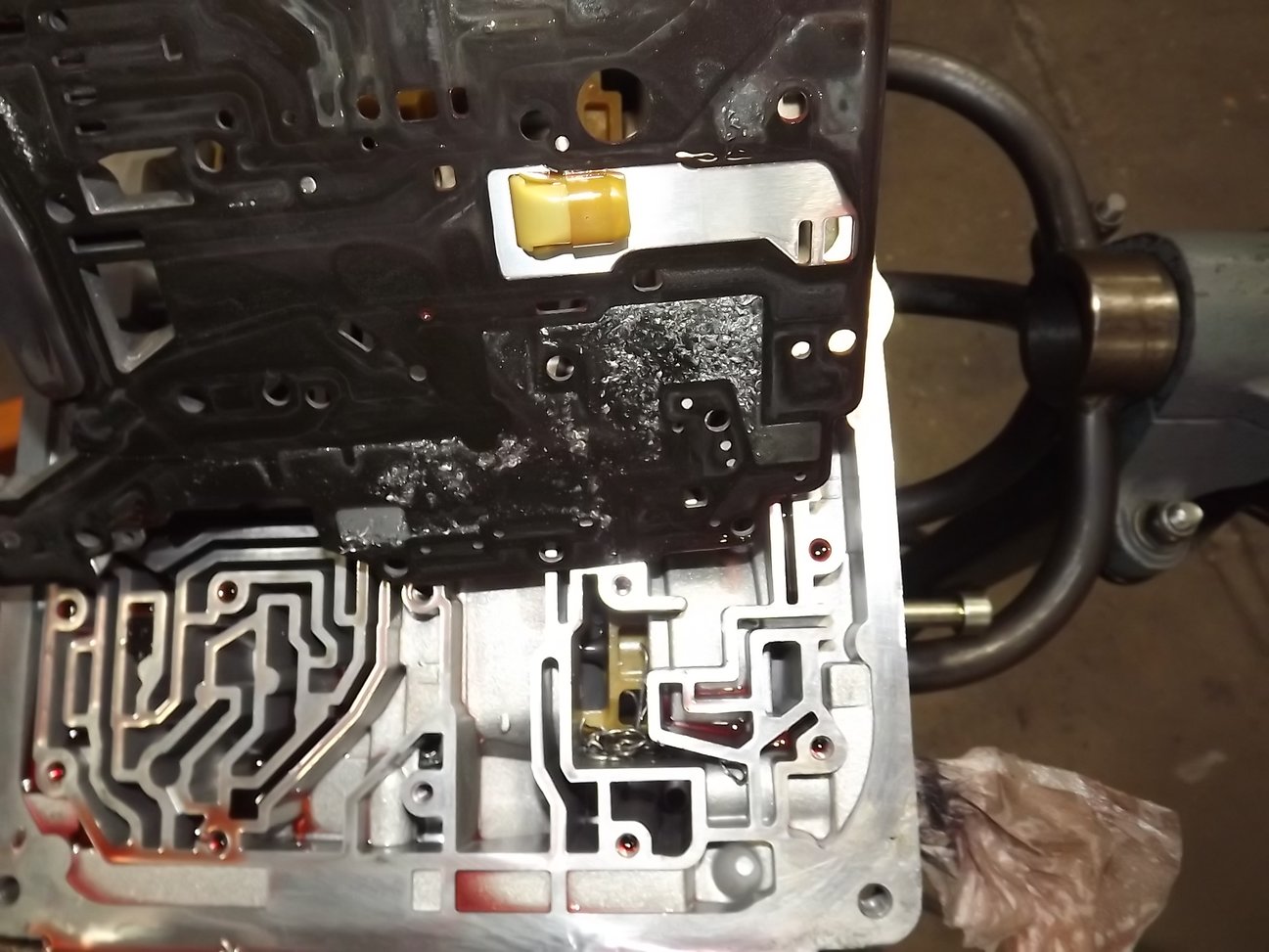

Removal of the oil pan will generally show lots of "magnetic debris", but most

of the big debris is held captive under the valve body separator plate.

(I literally finished rebuilding a GTS transmission, with this failure mode,

Thursday before Christmas....and I have some good pictures of the failure on my

computer at work, which I can post Monday, when I return.)

2. The second failure mode is more subtle and not nearly as common.

The B3 clutch disc will wear until there is no longer any clutch lining, just

the metal plate the clutch material is glued to. These transmissions very from

"Mode 1" failure in that the distance that the B3 piston needed to travel was

less than the distance in the "Mode 1" transmissions. (A distance difference

during initial assembly.)

B3 springs may still go into "coil bind", but there isn't enough travel to force

the spring retainer (bending it, however) over the round retaining ring.

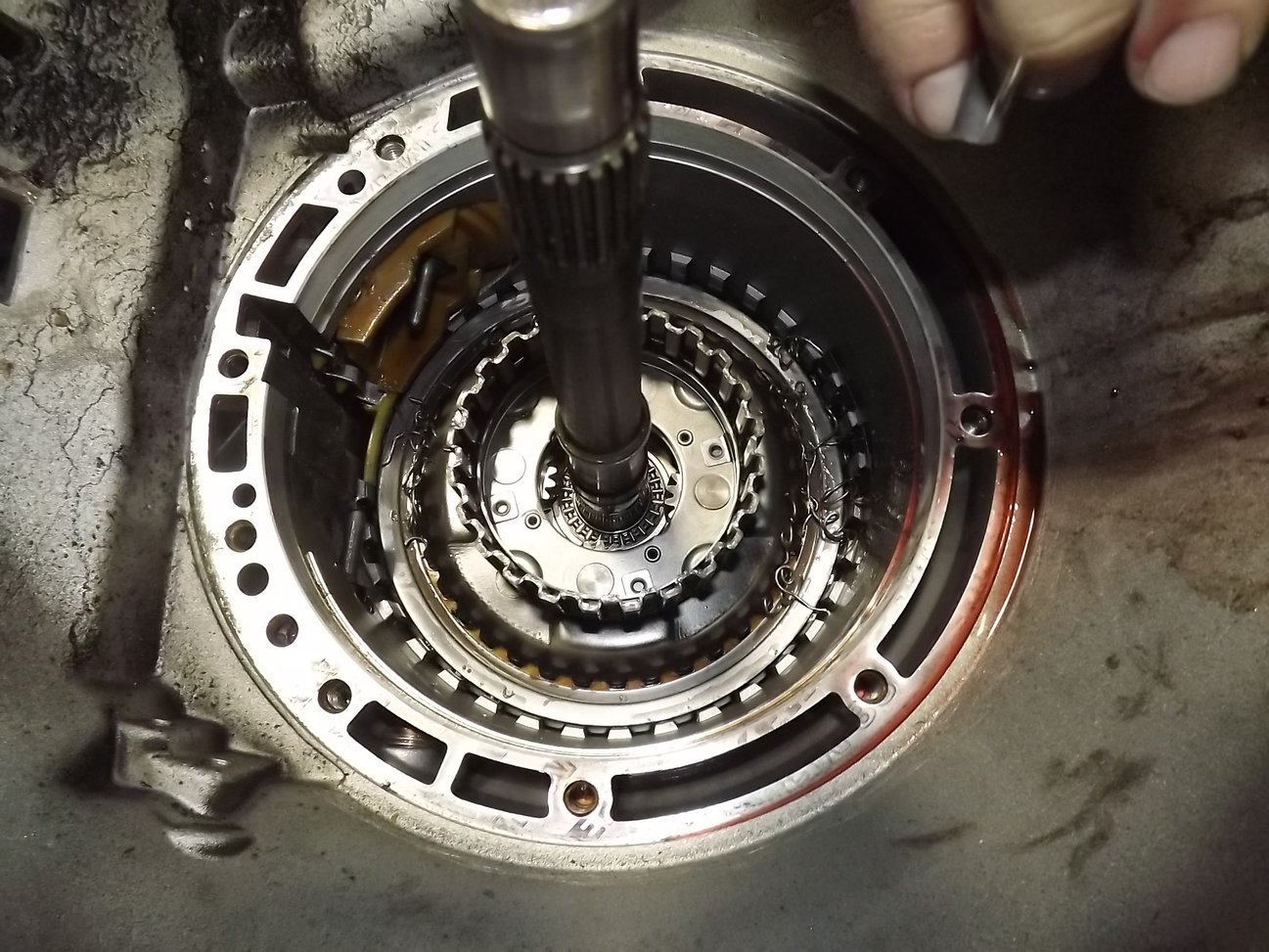

Instead, the clutch disc closest to the edge of the front planetary drive hub

gets thin enough to "slip off" the hub and then go under the hub, between the

hub and the planetary. Really bad things occur...resulting in the destruction of

the planetary.

(I have detailed pictures of this failure, also.)

So, is this the problem that the OP has?

I'm not sure, because either of the "Mode 1" or "Mode 2" failures result in the

loss as of reverse, initially,. The rear of the transmission, which has the B2

drum and clutches should still function....so 1st and 2nd gear should still be

functional.

I'm not convinced that there isn't a broken/detached axle or a broken torque

tube shaft, yet.

I'd continue with a test, with the rear wheels off the ground) where the

emergency brake is pulled and the rear wheels unable to rotate. I'd put the

transmission into 1st gear and gently have someone apply throttle while watching

the C/V flanges coming out of the transmission. If one spins, that is the side

with an axle problem. If neither flange spins, make sure the torque converter is

rotating under this same test. If the converter is spinning and neither flange

is rotating....shut the poor thing off, before more damage occurs, and pull the

pan.

BTW....A 100 quart Igloo ice chest (or its equivalent) makes a great shipping

container to get these automatics, complete with the converter to someone very

familiar with the transmission and the PSD differential (I rebuild many of these

transmissions.) The PSD which should always be measured for wear, be inspected,

have the initial pressure reset, and have all the differential seals replaced,

when the transmission is rebuilt. Most Mercedes transmission rebuilders won't

touch the differential section (and are not familiar with the "B3" clutch

failures.)

GregBBRD