----

Another factor is the leak down test, checking how much blow by there is at the pistons (rings and cylinder walls do wear). Using a tire pressure gauge on a compressor, but with a spark plug adapter fitted at the end of the hose, I identified rings as the culprit on a single cylinder ... and knew I had to pull the motor. All other cylinders would take about 6 - 7 seconds to leak down from 100 psi to 10 psi on the gauge .... the one with a broken compression ring lost pressure in 1.3 seconds, with enough blow by to spin the basket in the oil fill throat.

Dave

----

1986 model:

Compression Results:

1: 170/170

2: 174/174

3: 167/167

4: 160/160

5: 180/180

6: 175/180

7: 175/175

8: 175/175

I repeated each twice. I did a third one cylinder 4 and still got 160-161. Car was thoroughly warmed up. Not getting the power I'm used to from her. Still waiting on my leak down tester otherwise I'd have used my time while sitting in the garage.

As a general rule, 10% variance between the highest and lowest cylinder is considered acceptable, you are at 12.5%, and only one cylinder is that high. The other 6 are 9% or lower variance. Has the engine ever been opened up? If not probably getting close to needing a valve job.

----

I consistently got 185 psig when I last did mine [90 S4 motor]. I am advised a fresh build should give a bit higher number but 26 year old rings etc....

----

Ok, test done. Results not so good. 5-8 175-180psi, 1-4 145-150psi.

When the two banks don't match that could mean cam timing is off.

Re: I recently encountered one 928 with this kind of discrepancy and the timing belt was installed one tooth off on the lower side.

__________________

Bill

----

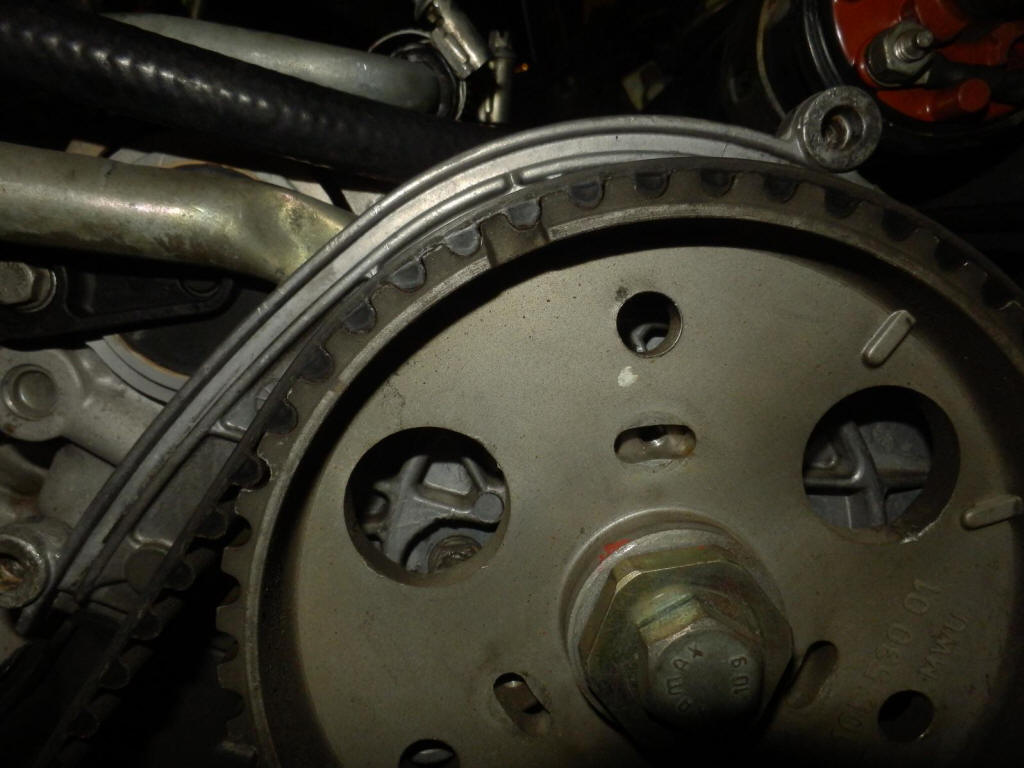

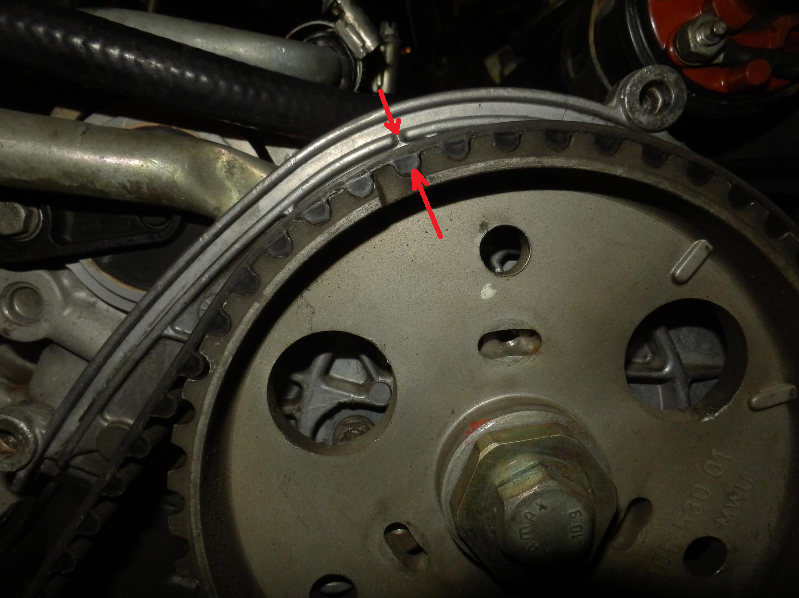

Your second picture (annotated below), cylinders 5-8, shows the belt position clearly with the trough of the gear tooth at the leading edge of the front slot lined up with the notch on the backing plate. PERFECT if the crank is at TDC. So, the belt is installed correctly for 5-8. Your first picture, cylinders 1-4, does not show the top of the gear, so we cannot see how the belt is installed on that gear. Show us that. The fact that the adjustment is skewed to one side leads me to suspect that someone tried to compensate for the belt being on the wrong tooth. Your goal is to have the belt within i/2 tooth of the trough of that tooth at the leading edge of the front slot (or better, the small notch on the back edge of the gear) lining up with the notch on the backing plate. Sometimes it is perfectly aligned, as you show for cylinders 5-8, but the goal is 1/2 tooth or less. The rest is taken care of with the cam adjustment slots.

__________________

Bill

----

At some time in the past, the belt was put on one tooth off and the cams were re-time in that position. During a subsequent belt replacement, the sprocket was re-aligned correctly but without re-timing the cams.

So me, being a bit slack at times, would do one of two things: re-jump the sprocket one tooth to the right or move the cam adjustment to the old bolt marks. Then I'd get the tools to align the cams and promise myself to do it soon and get to it in a year or two. Oh, and check the compression again and when it came up good smile and go for a drive.

This is the 1-4 cam-wheel: