|

|

|

|

Porsche 928 Tech: Check Your A/T Flex Plate By Richard Andrade |

|

Porscheís 928 was positioned as a grand touring car during its production life from 1978 to 1995. Given the V8 motorís high torque and the design focus to high speed comfortable travel, over 80% of the series production were equipped with automatic transmissions. This article addresses a service precaution for a high percentage of 928s on the road today. Porscheís 928 pioneered the use of a water cooled front engine and rear transaxle drive train. The engine and transaxle are connected by a solid torque tube with a driveshaft that runs at engine RPM. This design enabled the car to have a nearly 50% front - 50% rear weight displacement.

Figure 1. The 928 drivetrain layout.

The 928 automatic transmissions were produced by Mercedes Benz. The internals are basically the same as those in the "Mercedes S-Class" models of that time but with a sportier shifting profile. On the Rennlist internet forum, I had read about a problem with some automatictransmission equipped 928s where the drive shaft migrated forward and put enough pressure on the engine crankshaft to cause a failure in the engine thrust bearing. There is only one thrust bearing that controls "forward and rearward" driveshaft movement along the engine axis. Failure of the bearing allows the crankshaft to grind into the engine block which causes catastrophic damage. It wasnít until I was visiting Exotic Motorwerks that I realized the extent of the possible damage. Dan Warner, Exoticís owner, showed me an engine that was destroyed because of this problem.

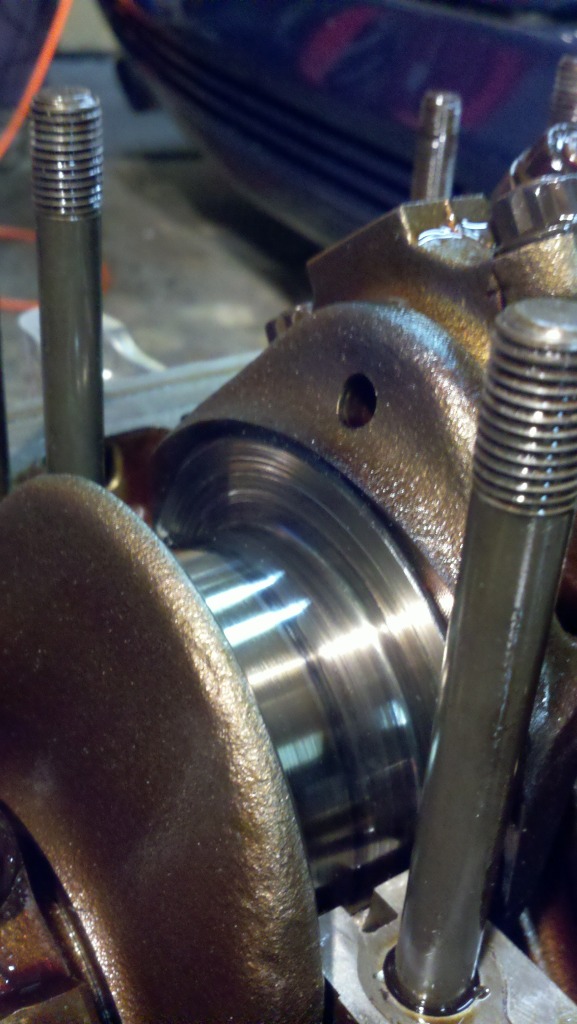

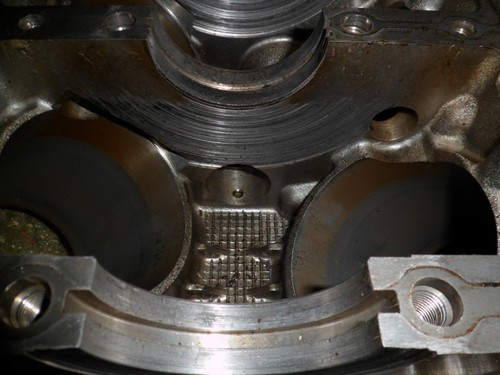

Figures 2 shows a new thrust bearing and the damaged block. Figure 3 shows the uneven crankshaft position as a result of the failure, and figure 4 shows the damage where the crankshaft contacted the engine block.

Figure 2. New Thrust Bearing and Damaged Block.

Figure 3. Failed Thrust Bearing and Resulting Uneven Crankshaft Position.

Figure 4. Block Damage.

Shortly after seeing the extent of the damage, I scheduled an appointment to have my 1993 928 GTS inspected. What I learned from Dan Warner was a simple one-hour procedure can reduce the odds of a thrust bearing failure. Iíll explain the procedure. To gain access to affected parts, the lower pan underneath the engine must first be removed. The exhaust pipes fit tight enough that they must be removed form the exhaust manifold. The exhaust pipes need to be supported as soon as the bolts are removed. By dropping the exhaust system the lower bell housing bolts can be removed and cover removed. Be sure that the oxygen sensor wires arenít stressed by the weight of the exhaust pipes. At the rear of the engine block is the bell housing. Inside the bell housing is the flywheel. The driveshaft connects to the flywheel via a coupler that is attached to the flex plate. Figure 5 illustrates my GTSí layout.

Figure 5. Flywheel, Flex Plate and Driveshaft.

If there is pressure from the driveshaft toward the flex plate, the flex plate bows in the direction of the flywheel. This distortion can be easily seen by placing a ruler across the flex plate. Figure 6 shows this distortion.

Figure 6. Bowed Flex Plate.

As illustrated in Figure 7, my 1993 928 GTSí initial reading was 8.1 mm of driveshaft spline showing.

Figure 7 Initial Spline Measurement.

To release the tension on the flex plate, the coupler bolt is loosened. The flex plate quickly snaps into an undistorted form. Dan made a precautionary one revolution hand crank of the engine to ensure all tension is released from the drivetrain. Figure 8 shows the flex plate as it should be, flat as the ruler.

Figure 8. Flex Plate with no Tension.

To illustrate the amount of tension on the system, Dan measured the driveshaft splines after the tension was release. As Figure 9 illustrated, there was 4.8 mm of remaining exposed splines. So the flex plate was distorted towards the engine by 3.3 mm (.13 inch).

Figure 9. Final Spline Measurement.

The factory torque specs for the coupler bolt is 60 lb-ft. Rennlist posters recommended cranking the bolt torque up to 66 lb-ft, so that torque was used. As soon as the coupler bolt is tightened, the system is ready to be buttoned up. While the exhaust system is loose consider replacing the oxygen sensor. Dan told me that the majority of S4 and newer 928s with automatic transmissions have had tension on the flex plate. Therefore, Dan recommends checking the flex plate tension at each major service. After all, if an additional one hour of labor saves the engine block, it is money very well spent! Rich Andrade |

|

|

|

|

|

|

|

| |

|

|

| |

|

|

||

|

|

||

|

|

||