hi,

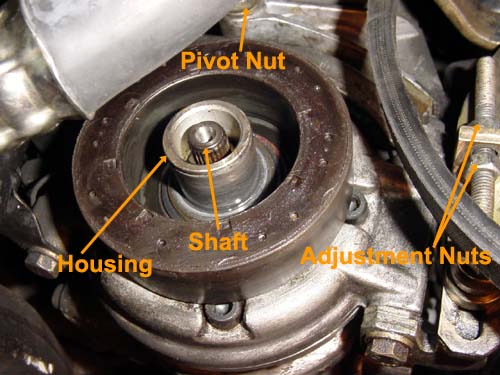

I had to replace the AC compressor clutch bearing of my 1992 GTS, a 10PA20C compressor. The clutch is basically a fixed rear coil unit that generates a magnetic field, an idler pulley that is belt driven and rotates freely when the clutch is not engaged, and a clutch plate that is pulled in by the magnetic field and thus couples the center shaft to the pulley and makes the compressor spin when the AC is turned on.

A bad clutch bearing is known as a grinding or humming sound when idling, which disappears with the clutch engaged.

Removing the clutch is not so hard, and no need to take the compressor off.

1. measure the air gap between clutch and face plate.

2. undo the 10mm bolt in the front. You may need a oil-filter clamp to counter-hold the front plate.

3. loosen the 13mm nuts and bolts that hold the compressor and keep the belt tensioned (one bolt at the front and rear, and two nuts on the tensioner bracket. Undo the belt.

4. pull the front plate off. It should slip off easily. Be careful, shims may fall out. You need them !!

5. you see a cir-clip that looks different. It is sort of a curly cir clip. It takes a normal cir-clip tool to undo the clip. A small screw driver may help to take it off.

6. the clutch part with the bearing in should slide off easily

7. the bearing goes out on one side, and you see some pressure points that were used to make sure the bearing does not slip out. (no reason to assume this would happen, and you need to crack through these 6 points by pressing the bearing from the other side,... see picture)

8. use a large socket and hammer to kick the old bearing out. The pressed bits will break and are not important. The bearing is a tight fit.

9. carefully position the new bearing and press it in using a vise or press. Do not hammer. Use the old bearing to press on top of the new bearing so that you do not damage the bearing race. The bearing is a A/C COMPRESSOR CLUTCH BEARING 30mm x 52mm x 22mm NIB AC. Model Koyo DAC3052-32RR9DS10Z. I used a NGK with same specs.

10. reassemble and check the air gap. Be very alert with that air gap. The shims are there for adjusting. As the new bearing might be seated differently, more or less shims may be required. In no case may the idler scratch the faceplate while not engaged. Check the compressor after reassembling and listen for sounds that may indicate not free running. Then engage and watch the face plate get locked in and make the compressor spin.

11. if all works, enjoy a test drive.

regards

Theo

1992 928GTS midnight blue

The Netherlands