It started off with

a question from Steve Davies about a high idle rpm. 1100 sometimes 900 rpm. 675

is the spec 25 and this is confirmed on my digital dash. The intake was taken

apart several times, swapped MAF, EZK and LH, checked every bit at least 3 times...

Somehow there is air getting into the engine which makes the idle control valve

unable to operate properly (idle valve closed but still too much air sneeking in

somehow). This is the summary of 13 pages of text...

Theo

http://928gts.jenniskens.eu

--------------

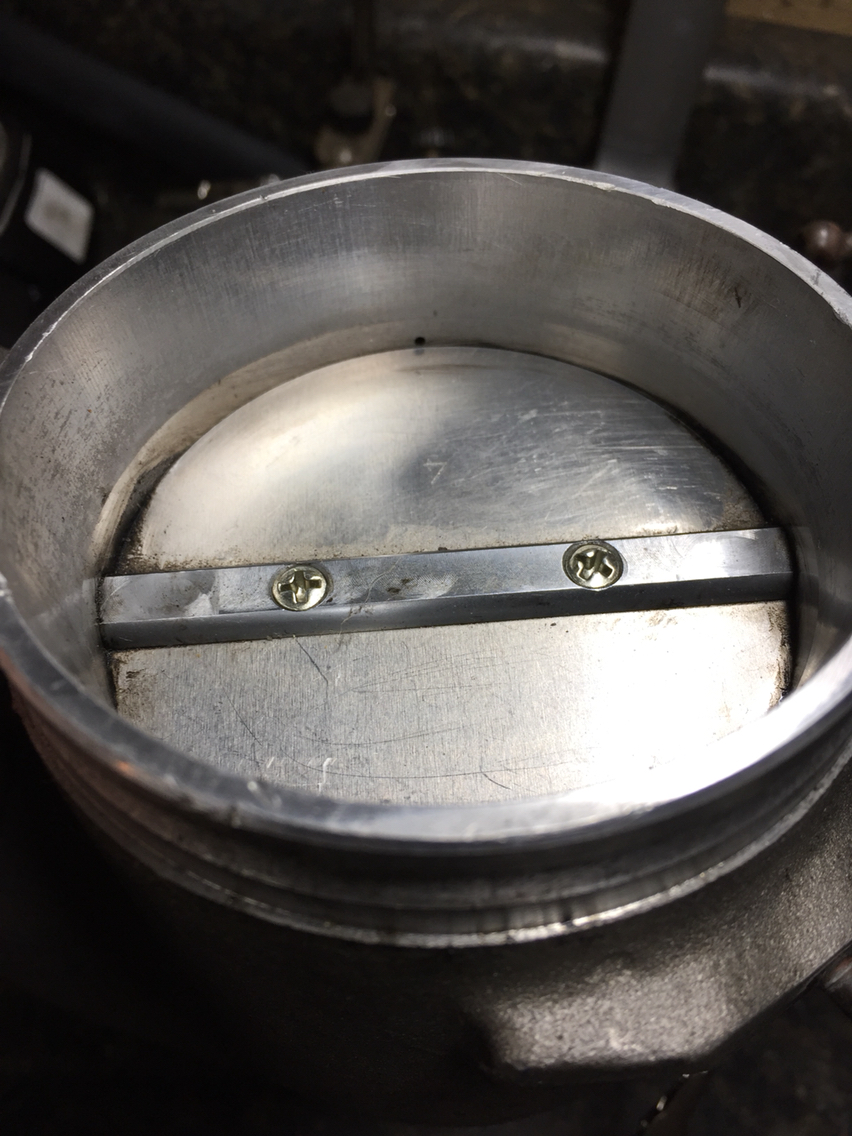

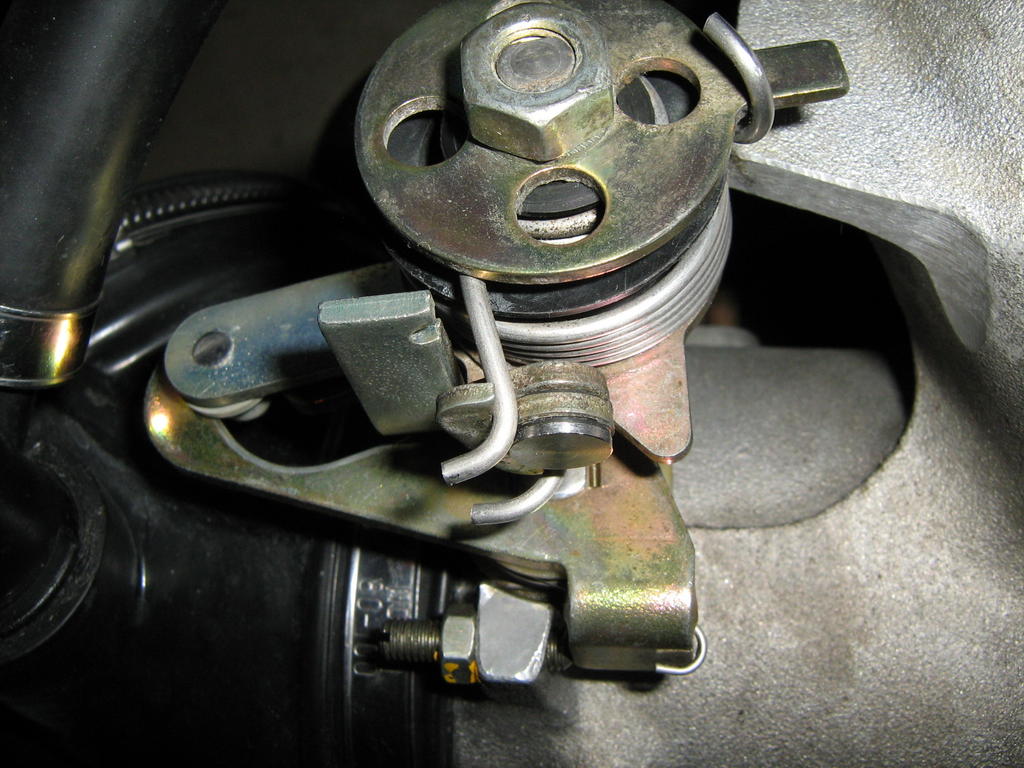

If I understand what you guys are looking for, I remember the throttle plate

being completely closed with almost no detectable gap. And here's how the stop

screw was positioned when I recently did my intake refresh. I didn't mess with

it.

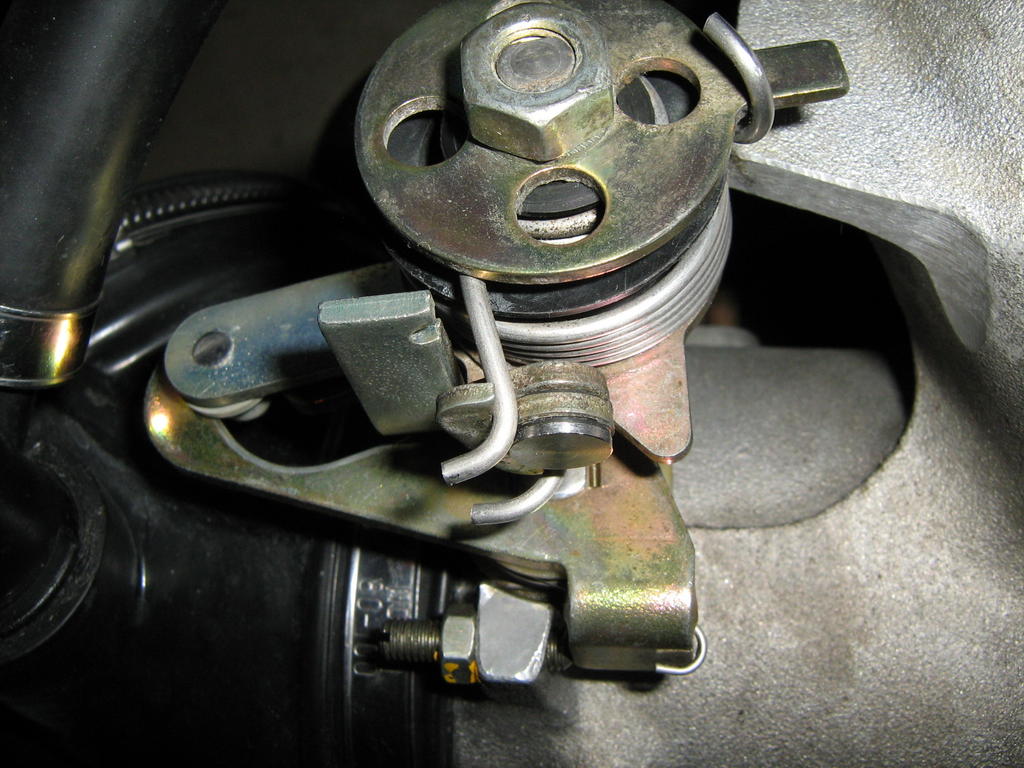

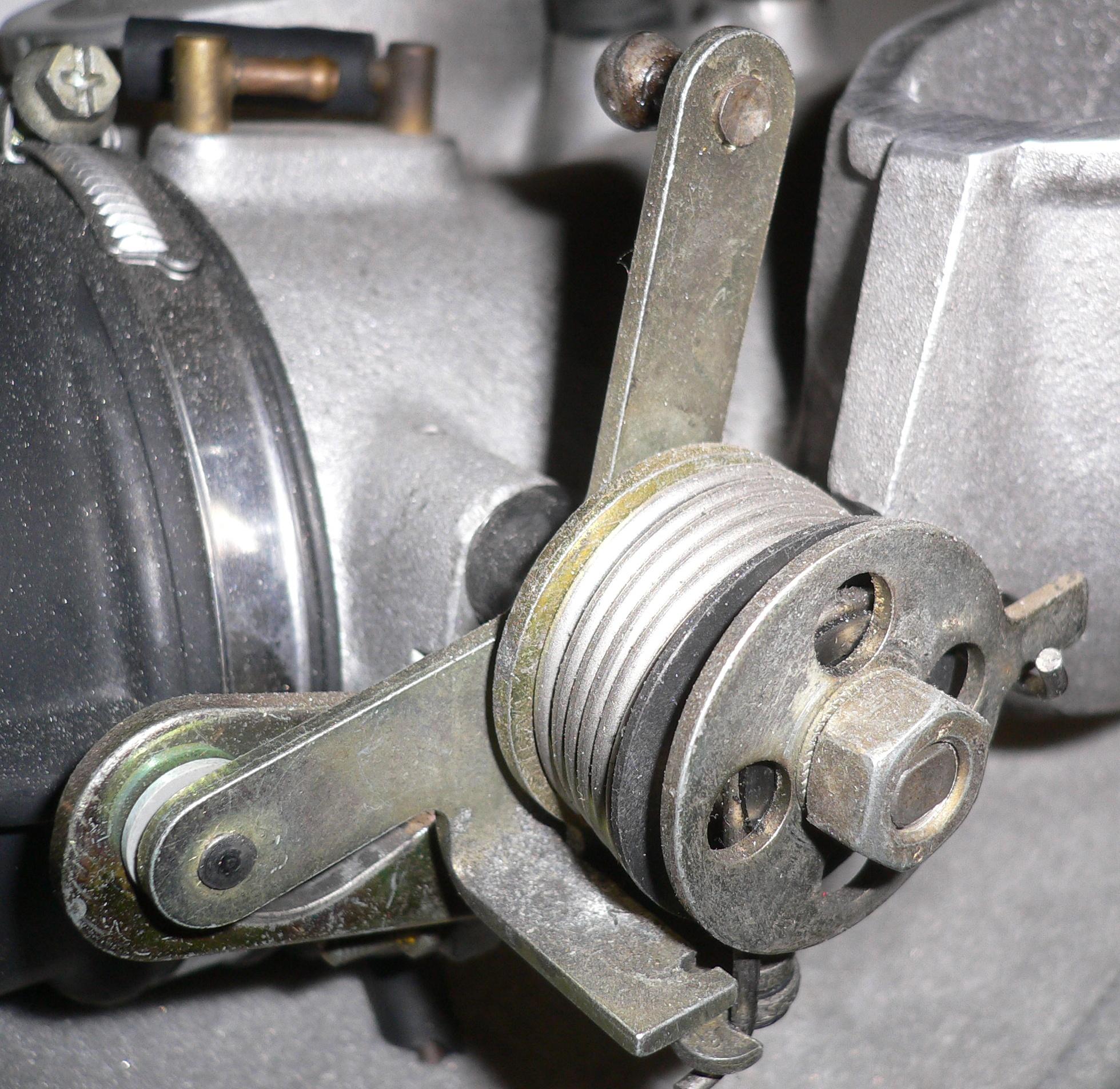

>>Do you recall if the throttle spring mechanism when closed hit the idle stop

screw or was there the smallest of gaps???

I'm pretty sure they were in contact. I used a feeler gauge there to adjust the

TPS position; I'm pretty sure I would have noticed if there was a gap there

before I started adjusting the TPS.

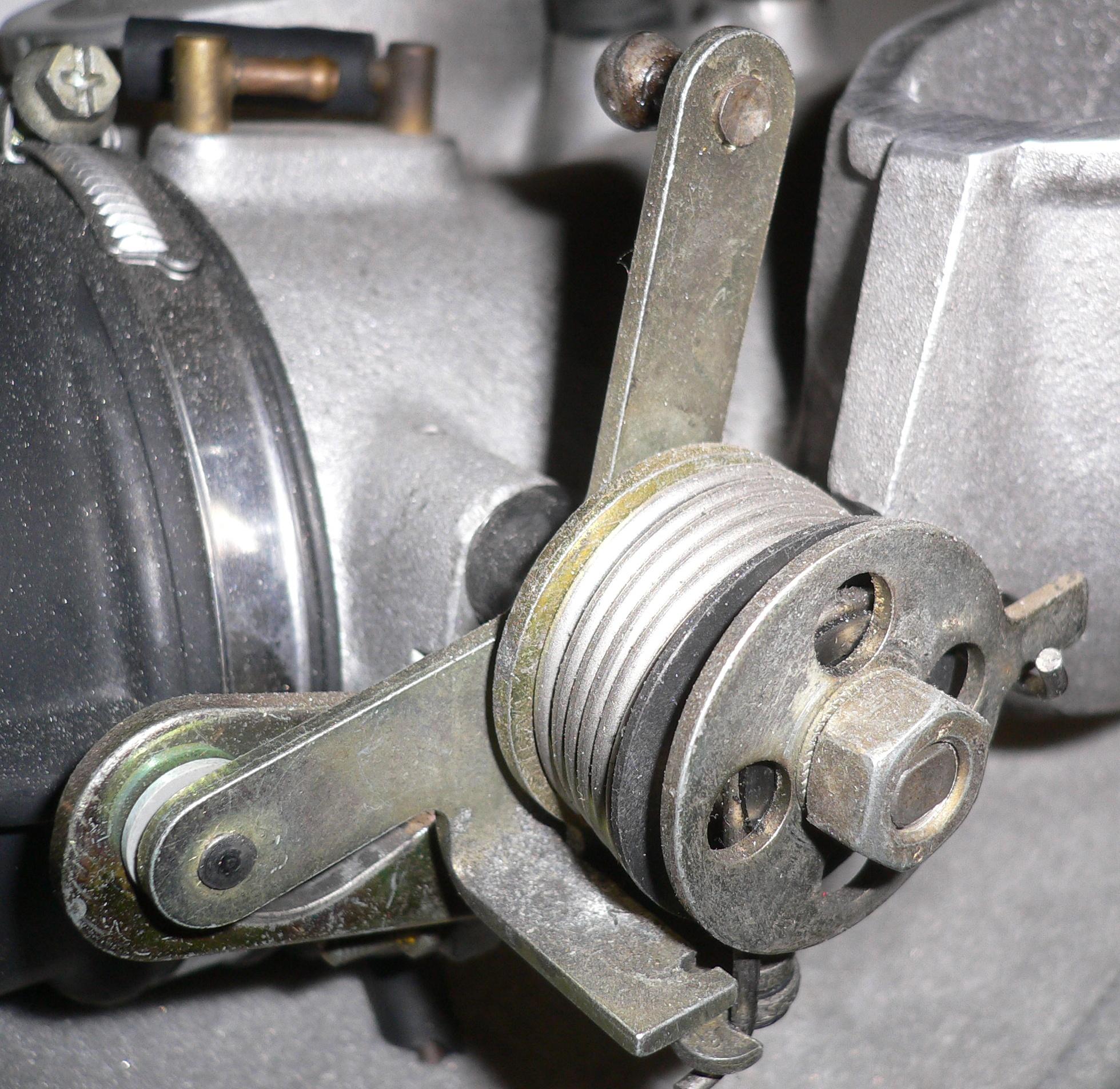

BTW, another thing (this is based on my not-always perfect memory; it'd be nice

if someone would confirm what I'm about to say): that tiny little hole on the

bottom of the throttle body (for the vacuum port that is connected to the air

pump air diverter valve) was just slightly inside the throttle plate when the

throttle was closed all the way. When the throttle plate is opened enough (just

barely) to trip the TPS idle switch, that little hole is the first location to

be exposed to the inrush of air due to the machined-out semicircle on the

throttle plate.

As I think about it more, if someone has a throttle body with a

known-to-be-properly-adjusted idle stop screw, that little hole might make a

good reference point. On the "reference" throttle body, you could stick a pin

through the vacuum port, providing a stop on the back side of the throttle plate.

Screwing in the idle stop screw (making damn sure to have the original position

marked!) and then measuring how far you had to turn it until the throttle plate

hits the pin would provide a repeatable procedure for setting the screw. I'm

guessing it'll be less than one turn of the screw. Then we'd be able to have

instructions like: insert pin (or wire?) into vacuum port. Tighten idle stop

screw enough that it stops at that pin/wire. Then back the screw off angle (whatever)

degrees. Remove pin/wire. Done.

Ed Scherer

-----------

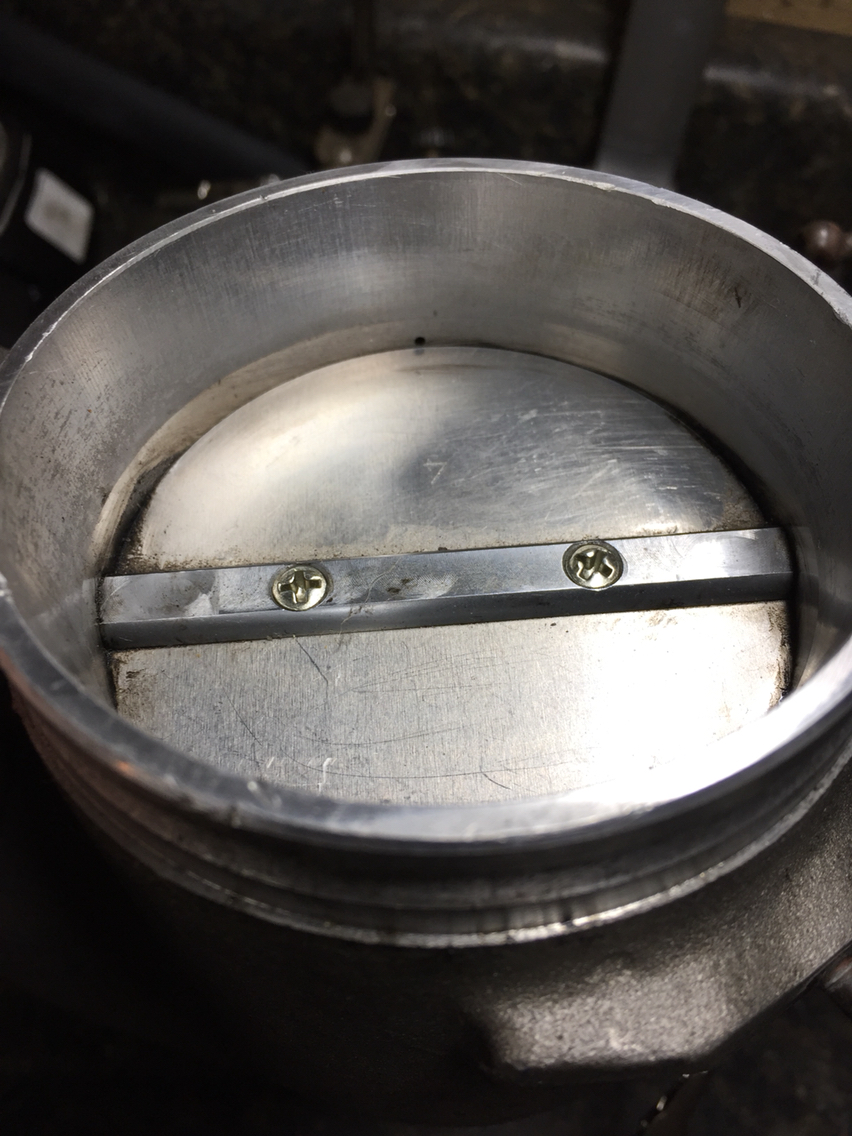

Maybe I can be of more help than my last post in this thread...my intake is off

now and I looked at it and the throttle plate has to move back about 5/32"

before the hole Ed mentioned shows. It appears in the pictures that maybe the

throttle stop isn't hitting the adjusting screw so I wonder if the throttle

plate is misadjusted and it didn't get set right after you rebuilt it.

__________________

Fred

1990 928 GT

-----------

Superb Fred..................thx so much.

Your pics confirm that when closed the t.plate blocks the lower vac hole but

when slightly open the hole is uncovered and totally verifies Eds post.

Also, the last pic is critical as it shows the upper vac hole open despite the

t.plate closed.

Steve.........with Ed and Freds input I believe you have enough information as

to how the t.plate should be set with the stop screw.

__________________

Malcolm

'88 928 S4 A/T

------------

I forgot about that fuel tank breather vacuum hole at the top, just outside of

the throttle plate when it's closed. That is a perfect reference point. Great

set of pictures there!

It's also interesting to think about why each of those vacuum ports is where it

is... all carefully designed to provide vacuum only under certain conditions.

That air diverter valve vacuum port hole at the bottom is amazingly small

diameter. Seems like that could get plugged up very easily.

-----------

Use the WSM to compare the 94' GTS

wiring diagram to the 93' GTS wiring diagram.

The plug pin numbers are indicated on both wiring diagrams. Sensor pin number

are only indicated for 94 GTS. Don't confuse plug and sensor pin numbers as they

are different.

Here's a table. Sensor pin numbers indicated:

94' GTS_____S4/GT/GTS -93'_____function

pin 4_______ pin 18____________ (ground)

pin 5_______ pin 3 ____________(wide open throttle)

pin 6_______ pin 2 ____________(idle)

Yes, pin 18 is correct and not a typo; just like is shown in the photo of WSM

Vol 2.

For my S4, I used a feeler gage and continuity meter to check the idle setting.

Under the manifold at the throttle valve, there is an adjustable stop for the

throttle. Placing the feeler gage between this stop, and measuring continuity

between pins 18 and 2, I found:

- with a 0.006" feeler gage, meter reads continuity,

- with a 0.007" feeler gage, meter reads open circuit.

For the throttle position sensor adjustment, I'd suggest adjusting the sensor

until you get the same result. Good luck.

Borland

--------------

Throttle valve wrong !!!!

==========

This is what the correctly set butterfly

valve should look like. A very minimum amount of air will pass the valve at

idle, the rest is managed by the ISV and controlled by the LH. The position

setting should not be tampered with.