there is often

confusion about the washers used on the spindle that holds the shocks to the

lower rear arm.

This is the way to do it:

Be sure to notice the orientation and location of the flat washer and 2 conical

"beveled" washers in the rear suspension Pin assembly. The conical washers will

go in the concave recesses on each side of the wheel hub where the pin goes thru

it. The flat washer goes between the rear of the shock mount and the rear of the

lower control arm.

If your doing rear suspension work remove the link pins

towards the rear, This will accomplish 2 things.

1. you get to clean and roll them on a flat surface to make sure they are true

(usually the right side is bent from the wheel hitting a curb or a bad tow truck

ride).

2. you get to lubricate them . If you have any thick grease this can be used to

hold the beveled washer in the hub carrier, use anti seize or grease on the link

pins when reinstalling them otherwise they will soon begin to bind and rust..

All of this is a lot easier including R N R ing the rear shocks if the lower

sway bar mount bolt is removed and then slid backwards a bit.

---------------

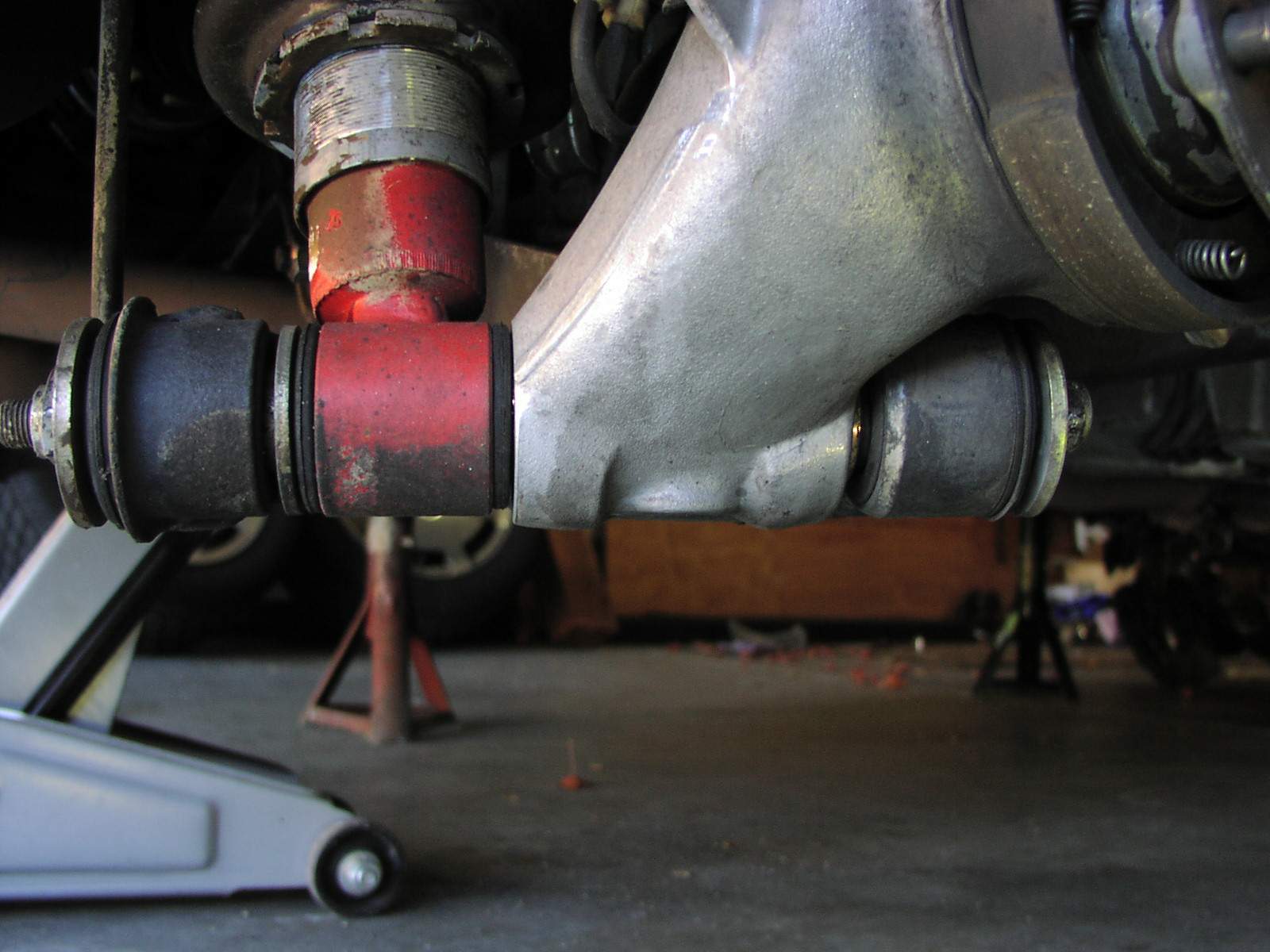

As others have already said, the conicals fit in recesses in

the sides of the hub carrier in the middle. There are only 3 flat washers, with

the ones on each end being larger and thicker than the 3rd one next to the

shock. As Dwayne indicated, there is no flat washer on the forward side of the

hub carrier. So, your driver side is wrong even though it looks right to you.

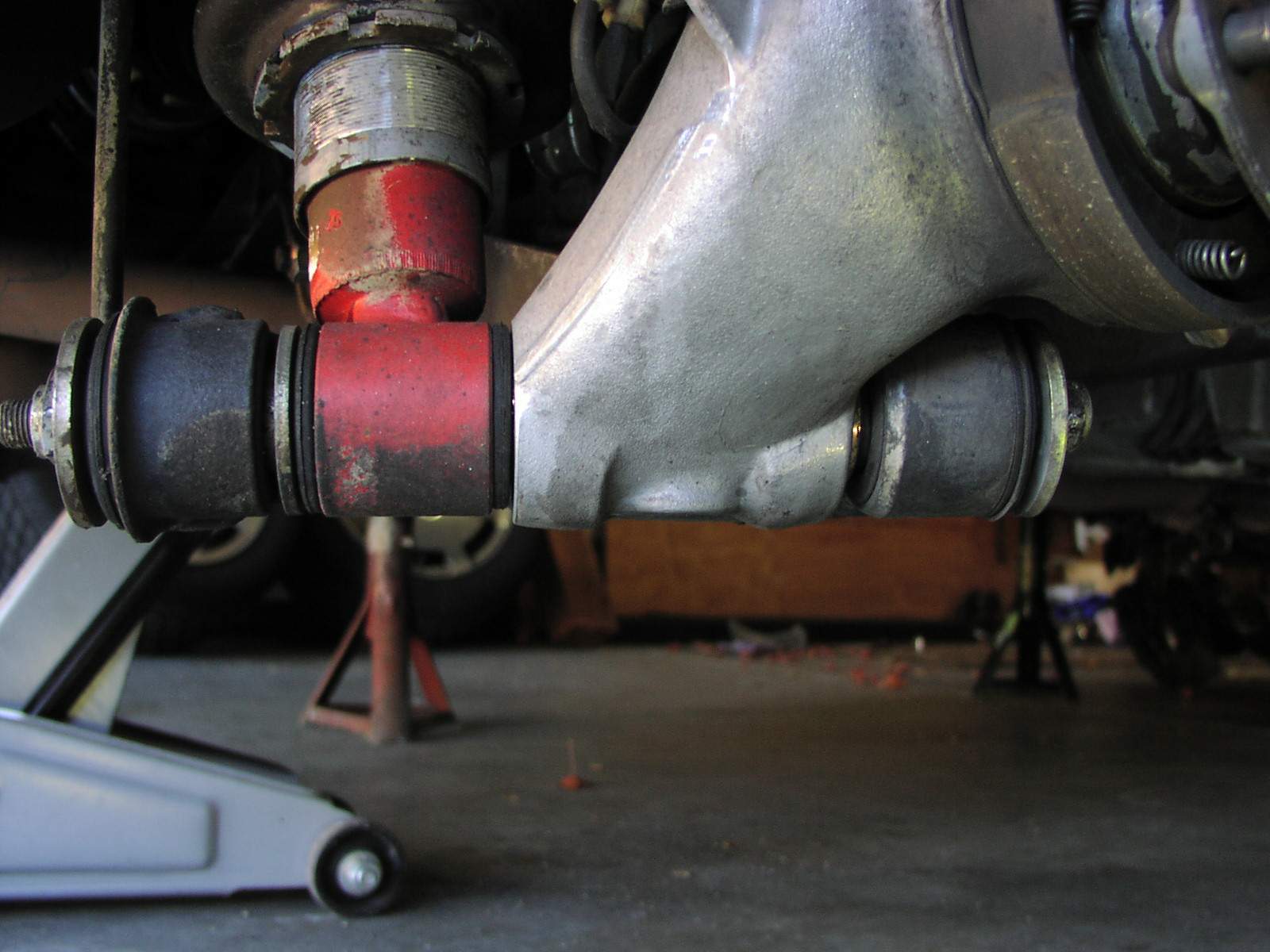

Here's the way it should look. There can be some "freespace" in the assembly not

filled snug with rubber bushing due to protruding metal centers in the bushings.

You can see some in my image, both on the forward side of the hub carrier and

between the shock mount flat washer and the control arm. The second image shows

the gap at rear due to the protruding metal spacer. Unfortunately, I don't have

a close-up shot of the front gap. Once the end nuts are torqued to 103 Ft-lbs,

there is no play.

The conical washers are missing or could be installed in the

wrong place. Seen it.

In this pic from the WSM, I labeled them "C" (for conical). When they are

installed correctly you cannot see them as they nestle inside the concave areas

of the hub carrier. Also, the nuts on the ends of the shaft need to be torqued

to 103 ft lbs. With the washers in correctly and the nuts tight, the carrier

should not move like this. Also, the other washer "F" needs to be on the other

side of the shock mount.

Bill Ball

-----

This is what the long pin (#11 in the above picture) looks like when it does not want to come out due to oxidation: