.jpg)

.jpg)

A different version from 928motorsports:

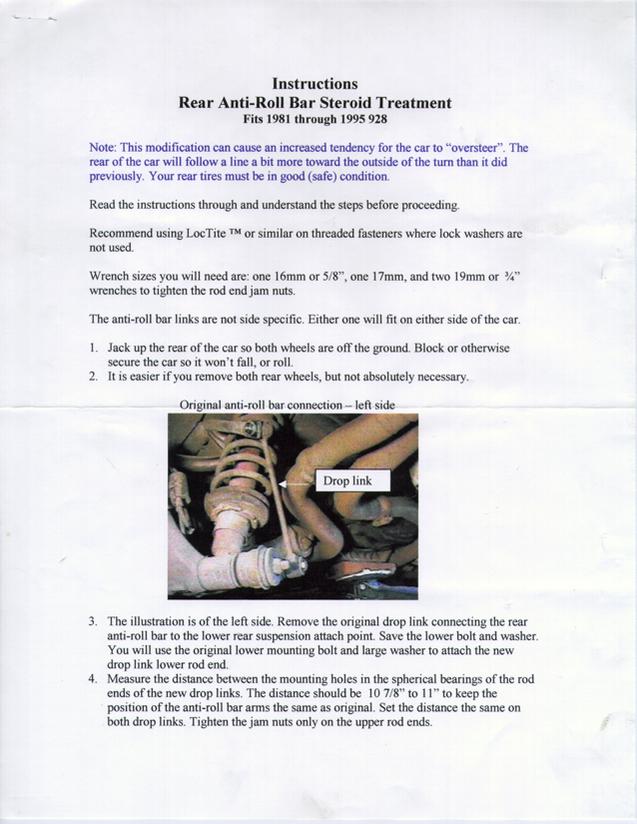

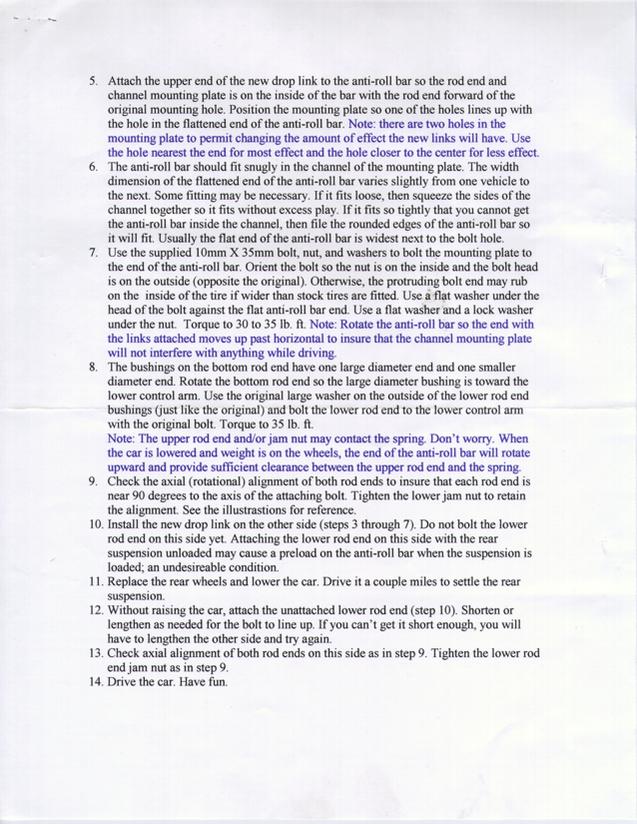

There is a serious design flaw in the original drop link. As the suspension axle turns a bit during compression of the shocks, and and since in the original design the nut is tightened against the new bracket which is locked against the suspension arm, you get the effect that the axle turns and un-screws the nut all the time. The result is a loose suspension and strange sounds when you drive over a bump.

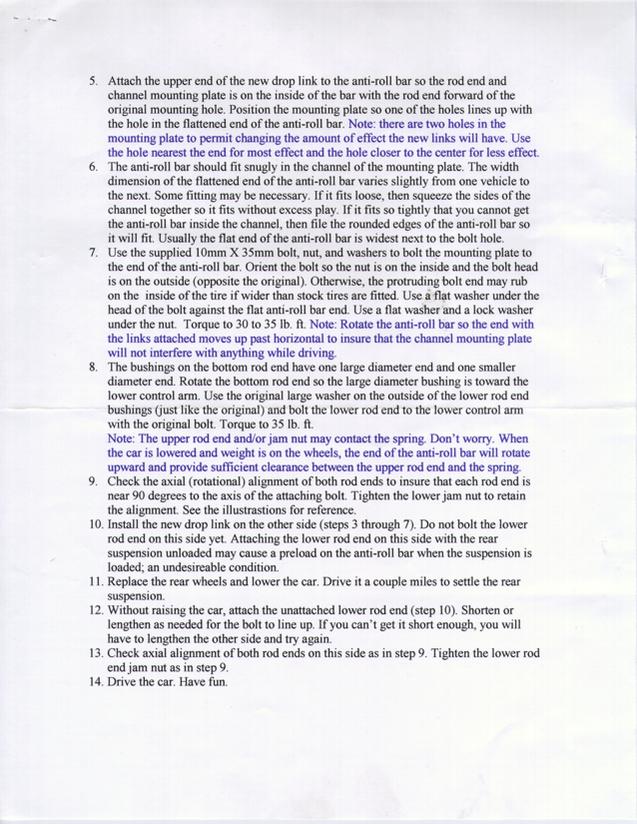

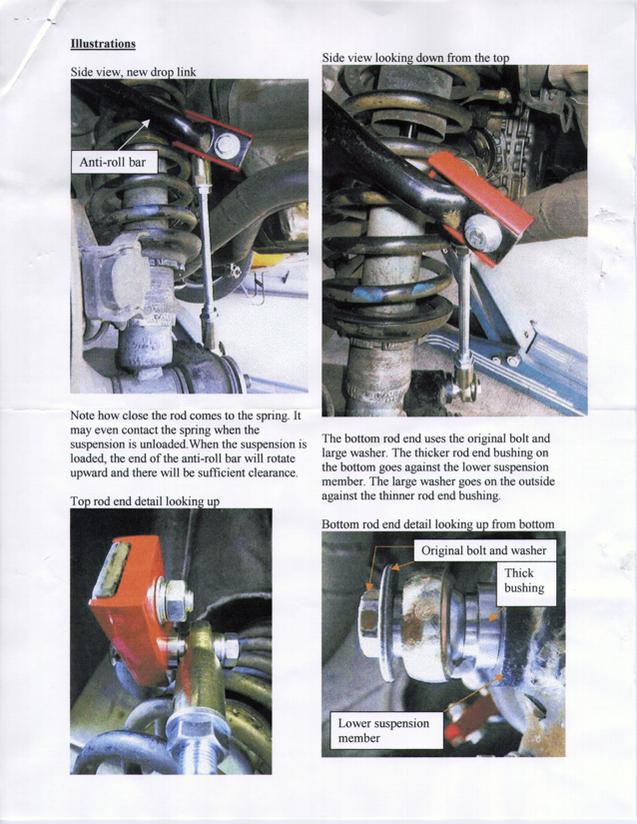

The solution (idea came from Rennlist) is this: tighten the nut against a big hat-style washer and make it remain flexible in the bracket using some grease. Here is my version and that works as a charm !!