On Sunday at the 928OC Spring Drive we

hosted, I shared my project which I have been working on for almost a year and a

half. The response was very positive and people are anxious to get it. So I have

decided to tell the world.

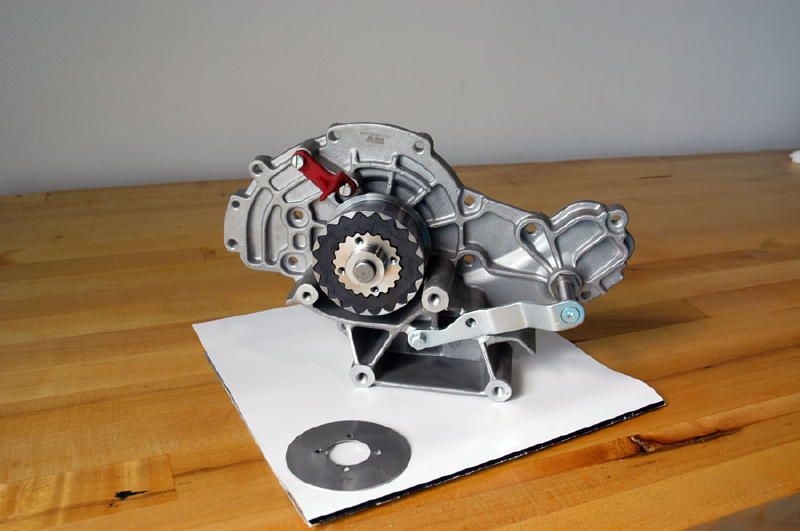

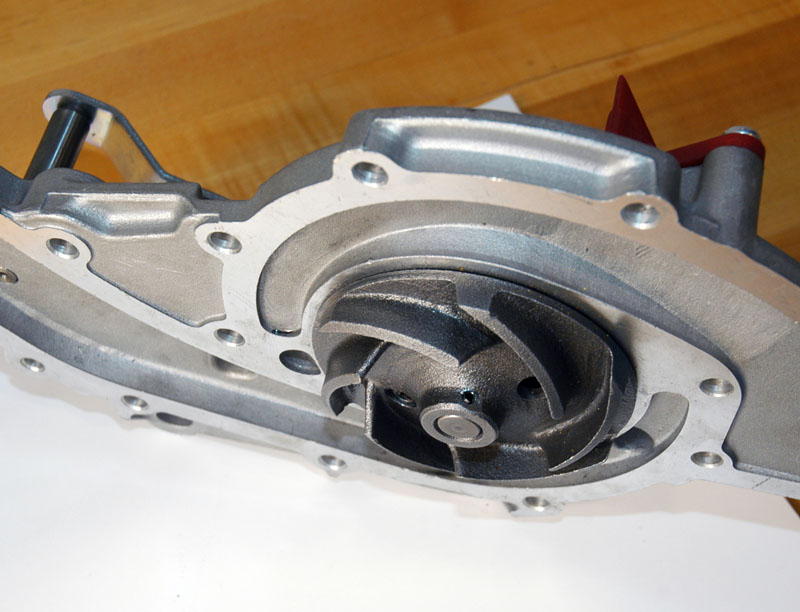

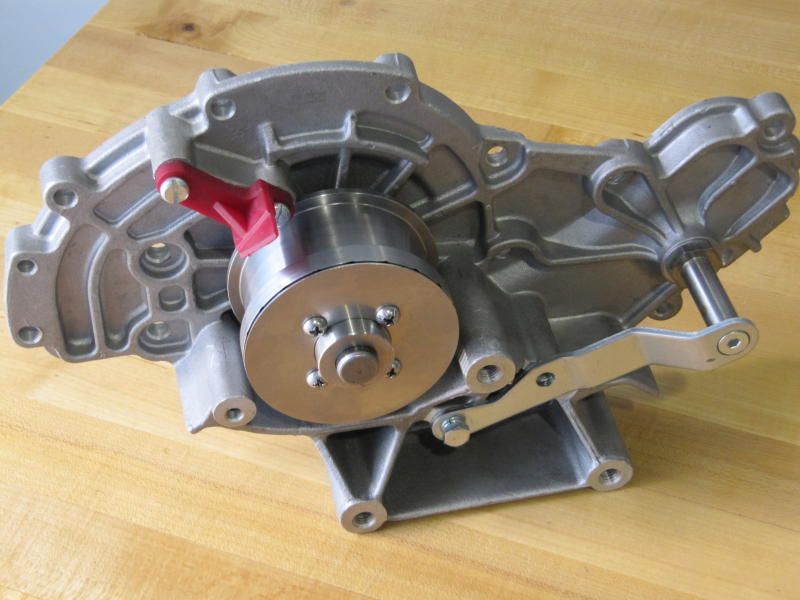

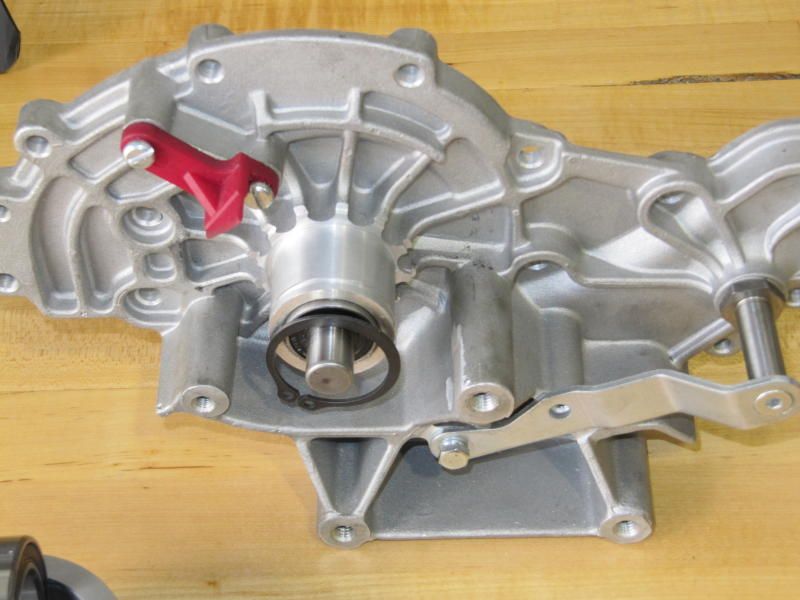

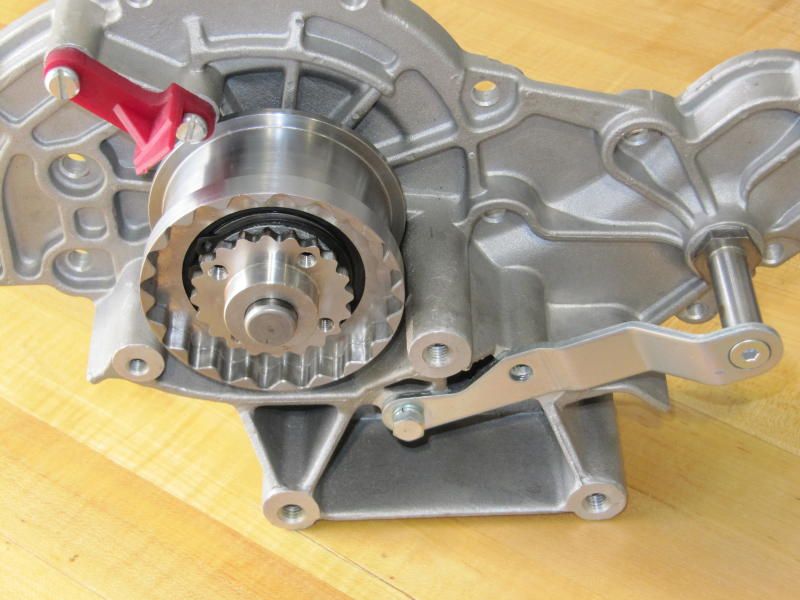

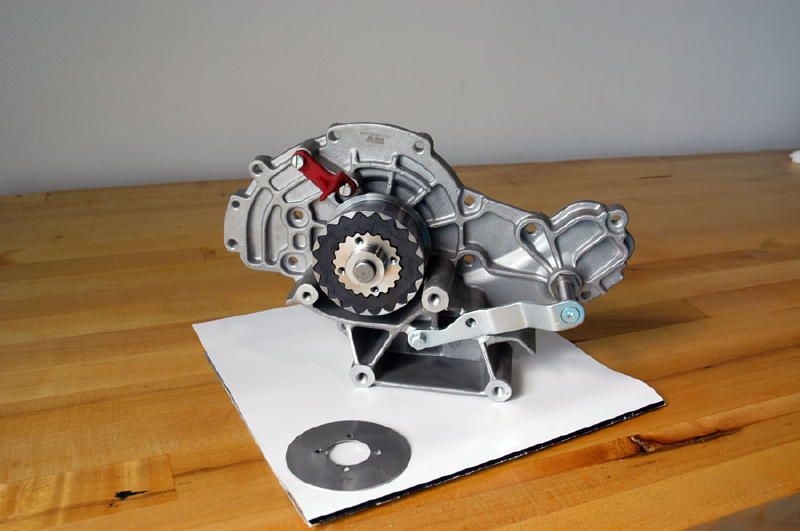

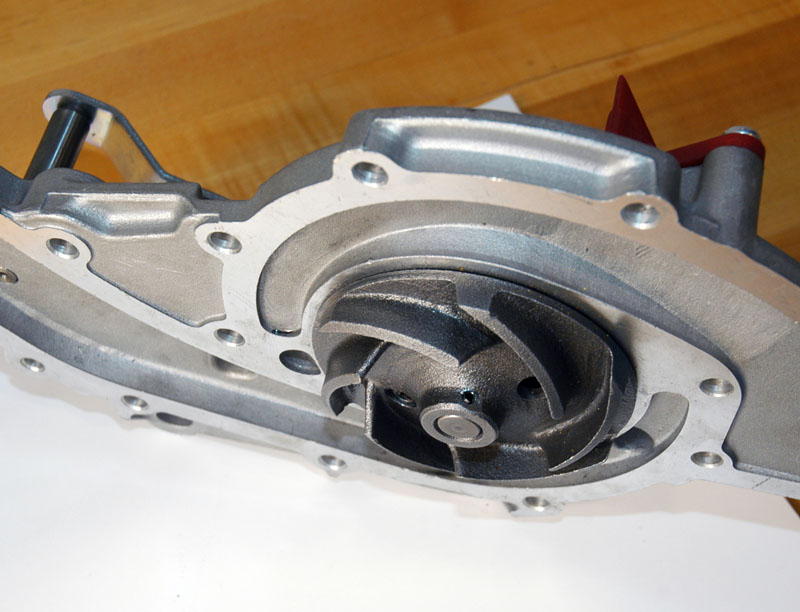

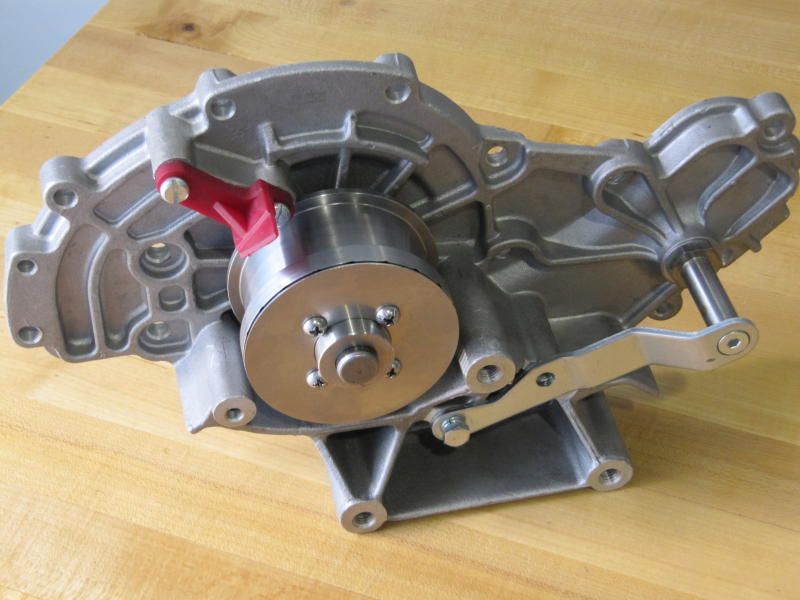

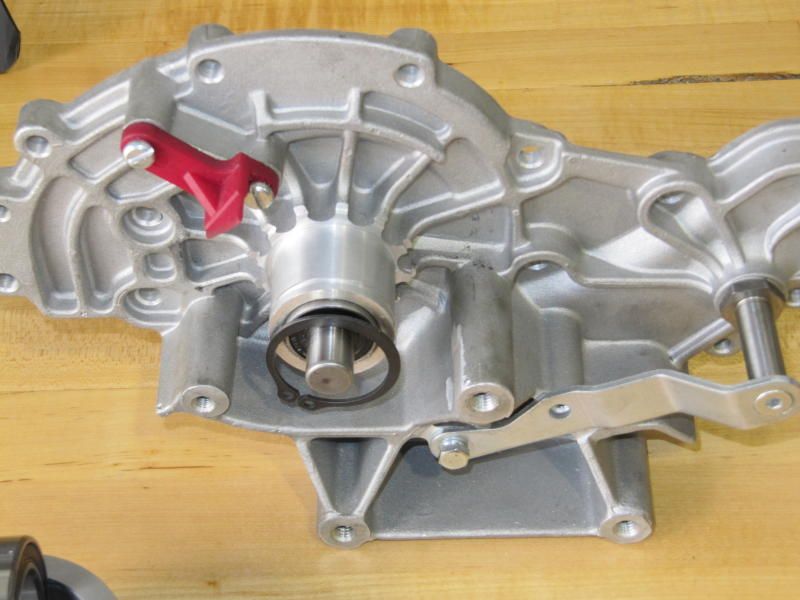

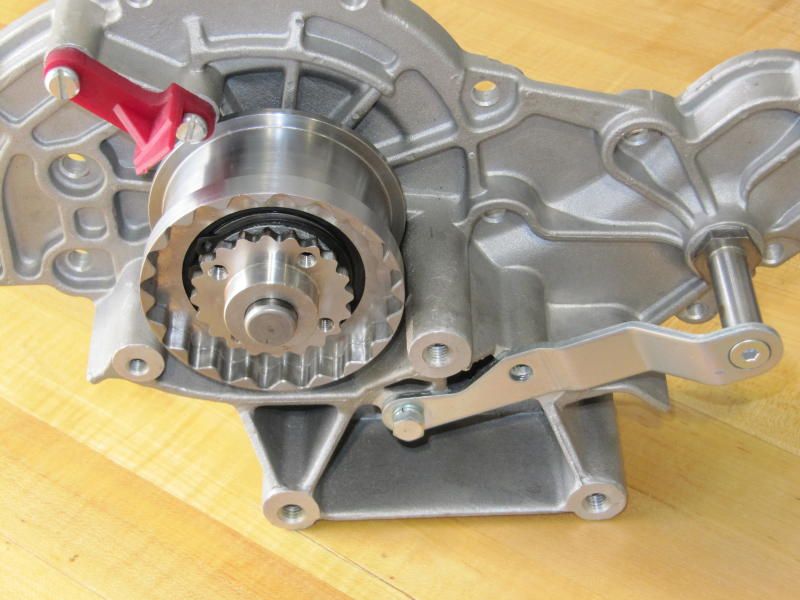

After much trial and error and experimentation i came up with an idea that works

and is proven. I have developed a system that mounts to a stock water pump

housing, prevents a metal impellor from moving, uses an extremely large double

ball bearing to support the load of the timing belt and its function, and

separates the direct contact between the water pump bearing, shaft and impellor,

meaning if for some reason the water pump seizes, the timing belt is unaffected.

Which means you will not bend the valves on your engine! All this and it is

serviceable to the extent that you can check both bearings at any time for play

if you are so inclined to. Also does not interfere with the timing belt cover

fit, no cutting or fabrication is necessary, and can be used with the porkensnr.

I have 3 of my personal cars fitted with them,2- 32valve 85s and 1- 16 valve 82

Bertha. I have just shy of one year on our daily driver which is an 85 32 valve

S and we have just clocked over 10,000 miles and no issues what so ever. No signs

of wear on either bearing. I also have one installed on Kevin's, (IrisandKevin),

85 Euro which has an 88 S4 engine with a supercharger on it for hard abuse. So

far after roughly 2500 miles on his car no issues.

OBehave

-----