DIY oil seperator

for boosted early 32V

--------------------------------------------------------------------------------

Today, finally got the engine sealed up and decided to make an oil separator

using Tony's concept. Since I didn't have to discard the oil filler neck (my SC

is where the AC compressor and air pump used to be) figured to use that as a

strainer box. I haven't yet tested it but as soon as the car is road ready, I

will report back with the results.

The existing oil filler neck vent port was re drilled to have the same diameter

as the hose. When I was drilling it, at the end, looks like it had some sort of

metal reducer, as the hole was very small but now it's as big as it can be. Also

added a second port on the adjacent side. The filler cap already had the venting

port that I installed back in '05 (when the SC setup was built). All these 3

ports will be connected to a catch can (it was also built back in '05).

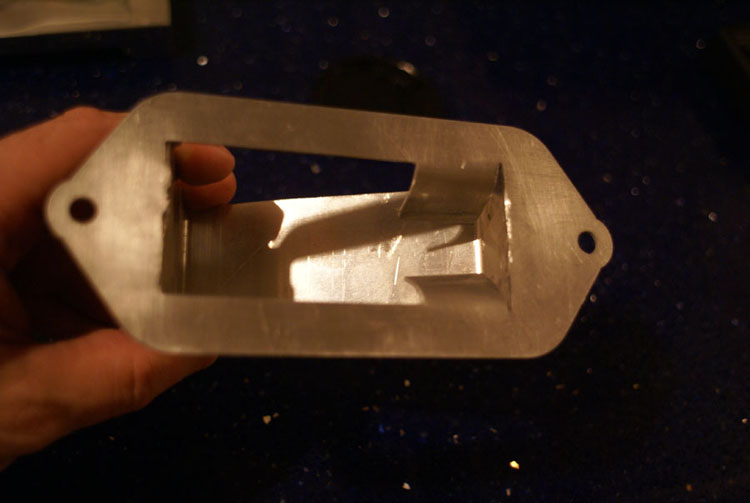

The first part of the separator is an aluminum plate that sits sandwiched

between the block, the OEM baffle and the oil filler neck. Above it is the OEM

baffle with slight modifications (more holes added and had to cut out the last

louver.

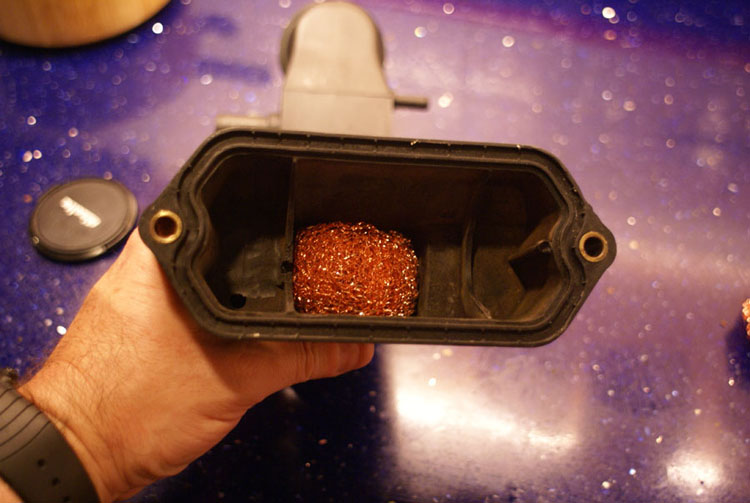

After this, is 1.5 rolls of Hefty Stainless Steel scrubbing pads filling the

bottom half of the oil filler neck.

In theory this should all work and the catch can should receive a lot less oil

than in the past. I would like if it was non or, very little but, even if it's a

reduction, I'll be happy.

Imre

1985 928S, 5-Speed

-----------

Custom Provent/Sharkvent Install

--------------------------------------------------------------------------------

I have been posting in DR's Sharkvent Post about my plans for a custom Provent/Sharkvent

install.

In order not to dilute any further DR's showcasing of his production Sharvent

systems I decided to create a separate thread. Not least because HermanK who

also owns a '94 GTS has expressed interest in doing a very similar or even

identical install.

I'll repost some things from the other thread for context too.

My goal is primarily to solve the GTS oil ingestion issues - which are pretty

severe on the GTS - even in normal (for me) street driving. I do drive the car

hard but not excessively so and see that I burn about a quart of oil every

300-600 miles. I consider this to be way excessive - having to carry several

quarts of oil for a 1000 mile round trip is embarrassing...

I have found some good documents on how the stock GTS system works

I have also read lots of details on what folks have done to improve this

(especially Louie Ott) and even on what Porsche did on the later models to

attempt (unsuccessfully apparently) to solve the problem.

It seems that the increased stroke of the GTS significantly worsened a problem

that earlier 928's exhibited under extreme conditions (track/ supercharged etc)

Porsche did make some changes - moving the crank porting further up the filler

neck, adding a balance vent between the cam covers and fitting a shroud to the

cam cover PCV vent but these relatively minor changes didn't help much.

Louie has a compelling argument that you need a bigger vent and active oil

separation from the main crank vent under the oil filler. He also notes that the

PCV venting from the passenger cam cover is problematic since that cover tends

to accumulate oil/mist thrown up from the crank and the PCV venting runs counter

to oil drain back via the same passages.

DR has created a great kit of parts for various model years and many have

reported success with the base systems (ROG100, Sterling). However since I was

to be removing the intake and cam covers for powder coating - I had some options

that DR just couldn't build into the base systems (and expect to sell many).

I decided I could easily port all 4 possible ports in the cam covers. I could

also modify the oil filler neck and install a crank vent baffle/filler scrubber

system an evacuation port and block off the current PCV vacuum ports.

This concept gives 3 stages of separation:

1) The 928 Intl Oil Control Plate (baffle plate) down in the crank vent hole

2) A stack of 5 copper scrubbies up the vertical (+horizontal) oil filler neck

3) A provent Air/Oil separator to follow these evacuated solely from the filler

neck.

The Provent drains back to the sump and in fact uses many of DR's Sharkvent

parts: mounting bracket, dipstick oil drain back with check valve, various

fittings and tubes - thanks to DR for being very flexible on ordering custom

Sharkvent parts.

For the cam covers the general idea is to make all 4 ports fresh air inlet ports

only. These will be plumbed to the intake air box below the filter and fed via

check valves.

This way the flow is always down the head oil drains in the same direction as

oil drain back. Its either fresh air sucked in to the cam covers & down into the

crankcase or its head blow by forcing its way in the same direction (down the

oil drains).

In order to have ~constant flushing the provent output is scavenged by a

combination of all the stock intake PCV vacuum ports, some requiring check

valves and/or stock equivalent fixed orifices.

Since its possible the stock system has insufficient total breathing capacity I

also expect to include a blow-off after the provent into the air pump feed.

This is the plan - pictures of progress so far to follow.

Alan

-------

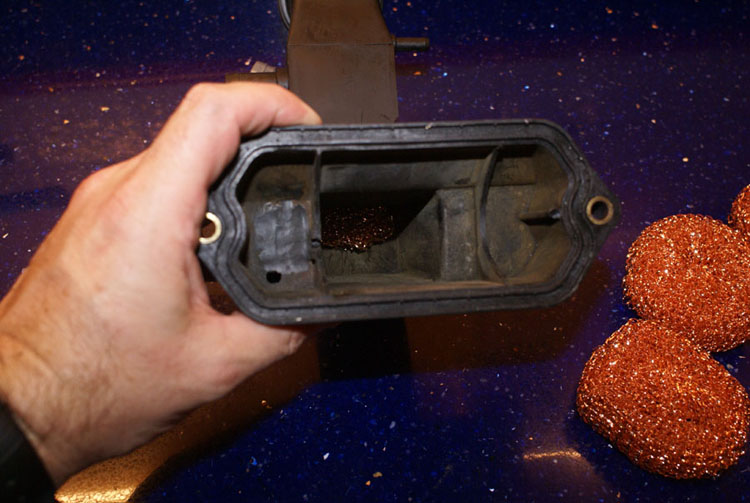

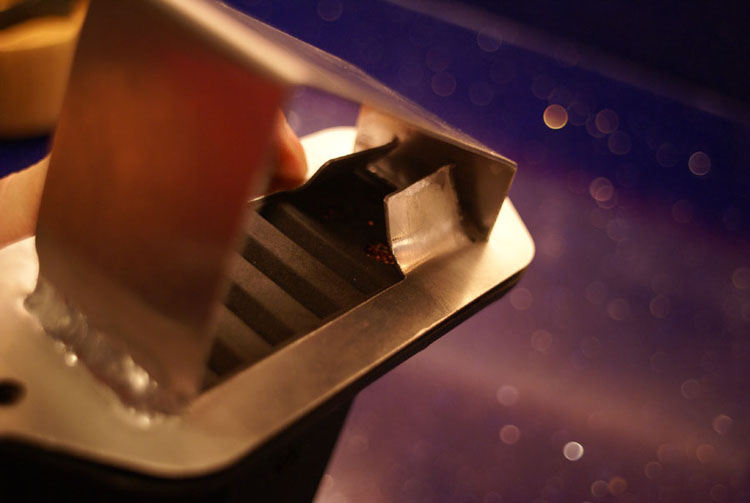

Here is a sequence on the filler vent mods.

Note the 928 Intl Oil Control Plate (baffle plate) that goes under the filler

neck in the main crankcase vent. I have modified this to expand the total intake

area - drilling a few extra holes in the filler bottom and creating some

secondary 'deflector wings' to protect them.

The oil filler has been opened up significantly inside the lower housing to take

more advantage of the side chambers - the support ribs still exist and are

functional but no longer get in the way of flow at the ends. The 5 pure copper

scrubbies are high strength types and (3) go all the way up the neck and even

around the top a little - as well as (2) spanning the whole filler bottom. The

stock filler bottom plate was drilled off its glued on attachment points. The

oil control plate has the stock old style filler gasket (+rtv) underneath and a

new o-ring seal on the top.

Alan