For those of you who’ve rebuilt and

fixed the 4spd automatic transmissions, this one’s for you. I’m fairly adept at

wrenching and fixing things as they should be, but this puzzler has me stumped.

And, after removing the transmission and replacing all the front seals, now the

problem is worse! I know, sounds like operator error to me too….

Searching the forums I found that Heinrich had essentially the same symptoms:

http://forums.rennlist.com/rennforums/928-forum/546708-4spd-automatic-transmission-leak-big-at-torque-converter.html

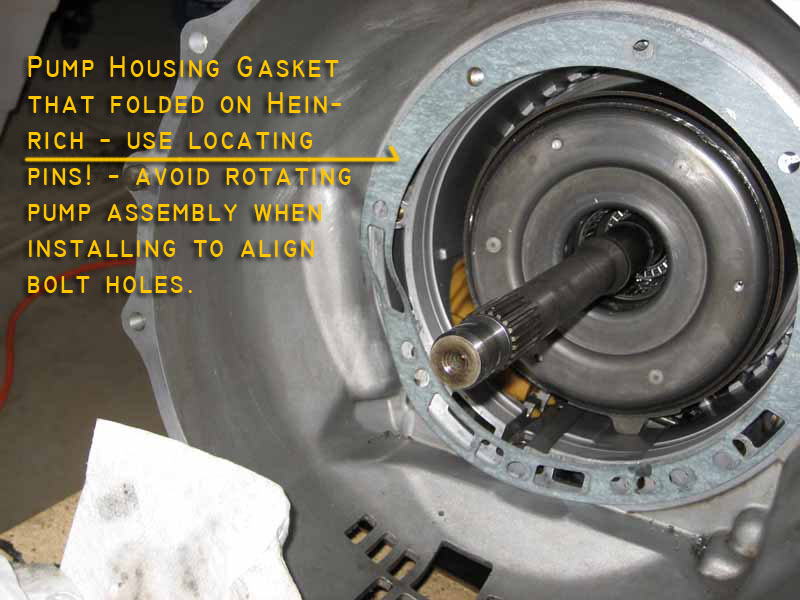

which turned out to be the front pump gasket damaged during installation.

Here's a pic from Heinrich's thread:

I guess this post is part ‘public

service announcement’ and part ‘what the heck’… I’m not pretending to be an

expert and I’m certainly not the documentarian Dwane is (you rock dude!); but

this was quite the challenge and I’m hoping this post will be one-stop-shopping

to help others trouble shoot the front end of the AT. It was bewildering for me

at first but after taking the time to study what was going on it began to make

sense and ultimately the job is very do-able… with practice (which it looks like

I’ll get more of). Also, Big UP to everyone here – I wouldn’t have been able to

do this without some awesome write-ups (Tony, Dwayne, & others – say where’s

Steve Cattaneo these days? – and Mr. Merlin) on this site and the amazing amount

of knowledge here. This community alone makes me want to keep this car forever

because I know an answer isn’t too far away.

Also, after reading other posts about cars catching on fire with leaky ATF

around hot exhaust, I consider this a HAZARDOUS condition – NOT drivable, NOT

safe. I’ve started my car when warm only to have a HUGE cloud of smoke pour from

underneath as ATF sprays on exhaust shields and parts. I’m a dad, I’m not

interested in being charred before my time. And, I’m thinking other folks are

running into this issue more as the cars age and running the other way…. So

here’s the scoop to help demystify what’s going on – everyone please lend your

additional $.02.

The Car: 83s with 117k original miles, I’ve had the car almost 2 years, driven

it maybe a total of 500 miles. (Yeah, that IS a problem…) Transmission was

leaking from the front grate (torque converter housing) just a little bit (like

it was low on fluid and taking air in) when I first got it, did a new trans

gasket, filter and fluid change to see if it might help. Torqued those pan bolts

(7 ft lbs is barely more than hand tightened) – no difference. Next, thought it

might be the front pump gasket/seal and/or the torque converter seal which means

pull the transmission so I thought I’d have a go at that.

Initial Symptoms: dripping leak in Park or Neutral from front grate TC cover.

Leak slowed when in Drive or Reverse (observed while car was running w/ P-Brake

on, flat and level surface). Trans level per spec (and I’m expert at this now…)

After removing transmission and replacing seals at front (TC seal, pump housing

gasket, main pump seal) the transmission practically POURS ATF when in Neutral

and Park and reduces flow by 50% when in gear (Reverse or Drive), still

dripping. When I start the car and the TC fills up I lose about 8oz of foamy

fluid in about 2 minutes!

Probable Causes (any others you all can think of?):

- Main Pump Gasket wrinkled / torn (Heinrich’s plight in the post above)

- Damaged TC O-ring (nicked or torn) from installing TC again

Scored / damaged / worn TC snout or bushing in main pump (replace both…) I

didn’t check these for wear tolerances as I’ve never seen any post or

information on checking these – not in the WSM either… Does anyone know of any

specs for such stuff?

- Low ATF level (wishful thinking…)

That last one has been curious and accounted for in other posts. Apparently,

when low on fluid the transmission will take on air and cause the ATF to foam

(teeny tiny bubbles) and then purge this foamy fluid, making it appear as a

leak. Same purge process as if the transmission has too much fluid. With

hindsight, I’m thinking this could have been my whole problem but I was too

inexperienced at checking the ATF level to know better – whether or not this was

the case, I was hoping to fix it and replace some old, tired rubber seals and

gaskets. Here’s how that went (pictures, with feeling now)…. Remove transmission

per WSM (exhaust, rear-sub-frame, etc.) – 2 days later:

Here’s the handy-dandy operating table I rigged up

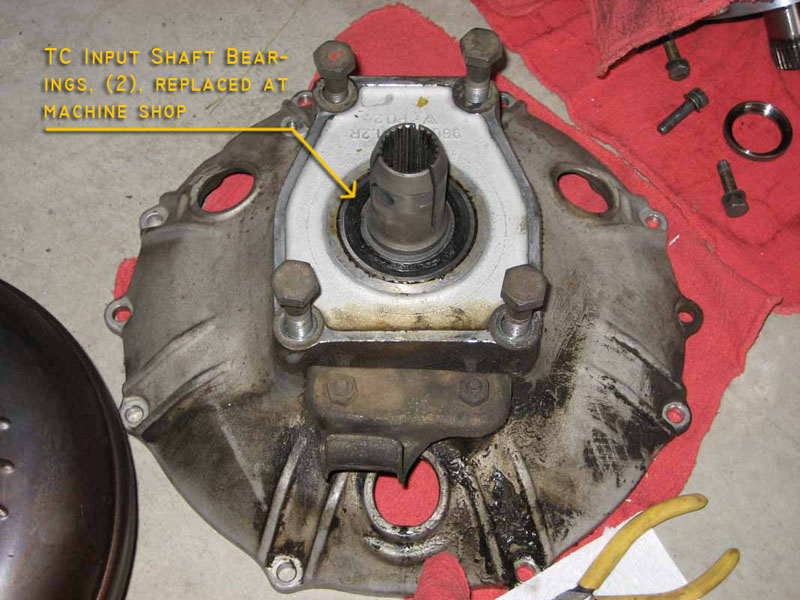

These are the TC input shaft bearings

which I had replaced – I would definitely have a machine shop push out the old

and press in the new. My shop had an oven to make the job smoother and not put

extra pressure on the housing or risk a crack… You also wind up pushing the flex

plate carrier and shaft back in – keep it straight…

Magical Front Pump (as seen from the front):

Here’s a picture of how the pump and housing all sandwich together:

Below is the gasket that seals the

interface between the assembly and the housing – this is the gasket that was

damaged in Heinrich’s post:

And here’s how they interface (note the

pump and the back piece shown in the following pic are not installed on to the

pump cover in this picture – yours should have that stuff on there!):

If you’ve searched around about this

problem you’ll find that you can’t get to the main pump without removing the

piston mounted to the back. I’m not sure what all this is but I’m sure I put it

back together the way I found it! There are another (2) seals that go on that

shaft as well.

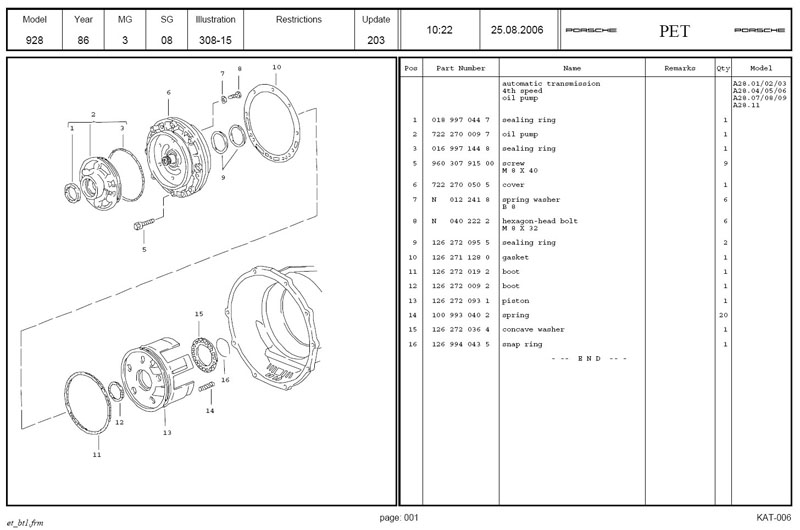

and here's a page from the pet that

shows how this all goes together:

Assembly is the reverse of removal…

(love that one).

I have to say, after doing all of this work, I’m pleased I could turn the key

and didn’t hear some horrible metal mashing sounds, and the car will move under

its own power. Unfortunately, there’s a post operation new symptom: driveline

shuddering when Reverse is selected (it’s so bad I move the selector to Park or

Neutral right away). It starts to shudder when the valve finally opens (or

closes?) and the brake band tries (I think) to take hold. The car would back up

but I’m afraid I’m gonna do some bigger damage…

Helpful hints for this procedure for those seeking the path:

- I did this job w/ those cheapo-short jack stands and (2) 2-ton $30 hydraulic

jacks – it can be done - but next time I’ll go for taller jack stands that

extend about 21”. Porken lift bars would be the bomb! And a floor jack that will

lift to 21-23” would be perfect. This gets the car off the ground far enough to

maneuver most everything including the rear sub-frame out from under the car. I

had to lower the front jack stands and tilt the car forward to get mine out from

the rear – what a bugger!

- Get all that stuff removed in the engine bay (airbox, MAF, cross brace etc.)

as that engine moves a lot. Also, this seems a common time to pinch some of the

hoses and tubing mounted to the firewall (brake line, fuel line, etc.) – another

potential fire hazard if you’re not careful. I made a practice of lowering the

transmission and checked clearance on the firewall just to make sure I didn’t

pinch something.

- Undo the tension on the transmission selector cable by removing the selector

hardware at the transmission or detaching the cable, if you don’t this will

stress the casing as the transmission lowers. New selector cables can be pricey…

And now I’m fully trained (er, I think so…) on transmission fluid level

checking. Researching I’ve found several perspectives on this (checking hot,

warm, and cold), however, after carefully reading the WSM (check it cold!), and

asking other experts, it’s best to do the following:

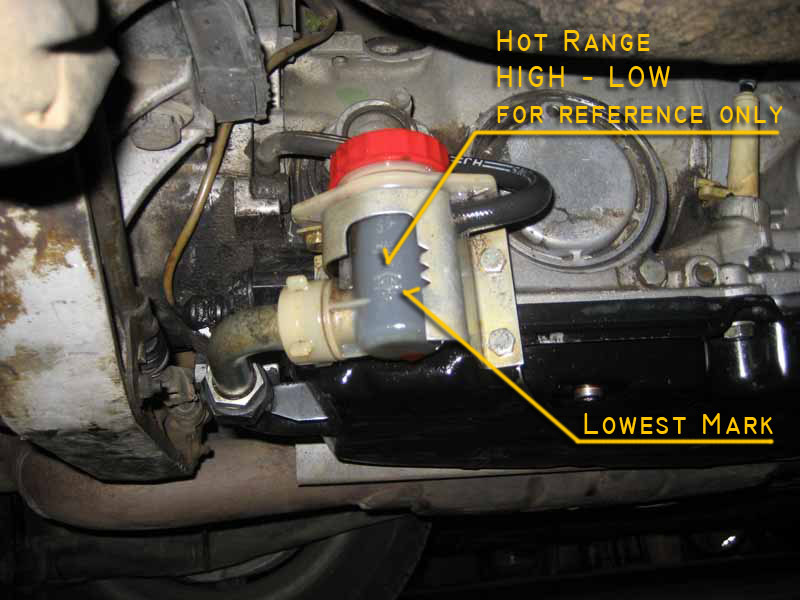

- Make sure the car is on level ground, parking break on, wheels blocked. You

need to be able to put the transmission in PRND and not let it get away from

you.

- Check the level COLD. Start engine in Park or Neutral and let the main pump

fill up the torque converter, this will take 2 minutes maximum. Check level – it

should be at the lowest mark on the reservoir.

- Put the transmission in Reverse for 15 seconds, in Drive for 15 seconds (to

allow the valves in the AT to open-close and put the car in gear both directions

– this ensures that the fluid is flowing throughout the transmission). Check

level – it should be at the lower mark on the reservoir.

- After these 2 checks, add more fluid if necessary to bring the level up to the

lower mark. You’re done, the upper marks are for “hot” transmissions which will

only happen after you’ve driven the car for 15 minutes and everything is up to

temp. I don’t think you’ll have “hot” fluid if you have the car running at idle

for 30 minutes while you’re checking levels, engaging transmission, filling with

fluid, etc.

- FYI, when the motor turns off and the TC stops spinning, it may drain AT fluid

back in to the lower pan and the reservoir will look completely full – see

picture.

That’s about it. If you’ve read this far you know what’s ahead for me when I can

finally pull up my bootstraps to get it done. My current mantra is: Always

faster the 2nd time! I may have to enlist some local supervision to hopefully

avoid a 3rd … (perish the thought… something about the smell of ATF…)..

to be continued...

-Paul

----------

To align the pump correctly there is an instruction in the WSM.

I made the 'A' mounting pins from two standard long shank metric bolts.

You can also screw two smaller bolts,

finger tight, in the threaded holes, and use them to grab the whole assembly

when making the fit-up.

When the unit is vertical, the pump housing tends to want to drop in place from

your hands, so a better grip is helpful.

Borland

---------