Thanks to help from Dave Overington in Australia and our own Mr Merlin we now have the "Ultimate" set of rack bushings. The set includes 8 bushes. One is inserted in both the top and bottom of the rack. This ensures no vertical movement of the rack unlike the old design. Available in Aluminium and Delrin for $70 a set.

__________________

Roger Tyson

Email Roger@928sRus.com or call 817 430 2688

--------------------------------------------------------------------------------

http://forums.rennlist.com/rennforums/928-forum/253374-steering-rack-question-4.html

Quote: Originally Posted by daveo90s4 Many many many supposedly reputable companies don't bother to peen the OEM rack bushes after fitting a new rack and new bushes. This failure then allows the rack to move vertically and results in lousy steering and excess tram lining.

I've read on rennlist previously that the aftermarket aluminum bushes - with no ability to peen and limit vertical movement - initially perform well but over time allow excess vertical movement.

The Delrin bushes that I am aware of likewise offer no facility to peen to limit vertical movement - but when tightened the are forced shorter and fatter so may stop the vertical movement in the long term. Who knows?

I think that making sure this bush part of the system is properly limiting rack movement would have to be the 1st thing to address in any improvement program (especially if excess tram lining is being felt even WITH correct 65ET front wheels).

I share the same concerns. The rack assembly's mounting feet are bored and machined on one side, but there will be some tolerance. An aluminum bushing will either be loose, allowing the rack to move up and down, or tight and require a press-fit, depending on how the tolerances stack up.

A plastic bushing may get fatter and tighten against vertical movement as the bolts are torqued, but this also is going to be subject to machining tolerances. And torquing a 10mm bolt against plastic makes me a bit uncomfortable.

The washer trick is not reliable either, in my experience. The rack in our GT had washers to lock it down (fit by the PO), and seemed solid on the lift, but it was still moving on the road-- when disassembled the surfaces of all four washers were nicely polished where it was trying to clamp the rack bushing.

What I wanted was a metal sleeve for the mounting bolts to tighten against (like the factory design), but Delrin against the casting-- aluminum is not a good bearing material. The top of the "feet" are also not machined, so some compliance on that side is needed.

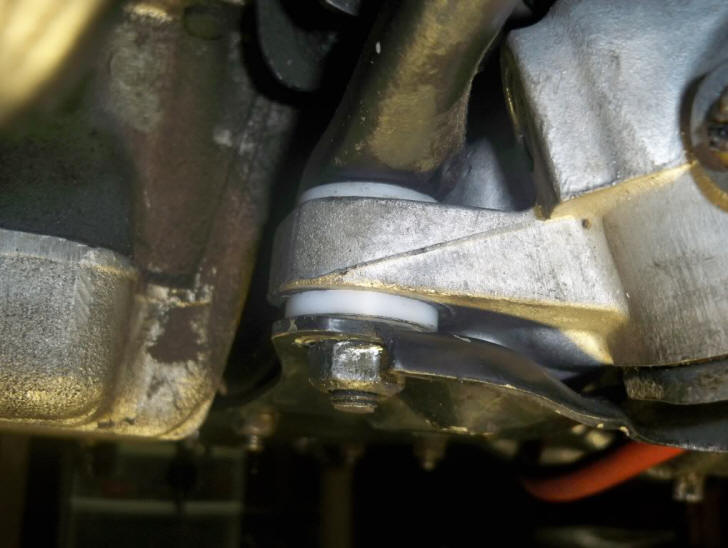

Here's what I came up with. This is a 3/4" OD x 1" long steel sleeve (original was 25.4 mm) bored to 10.3 mm, with a machined Delrin "top hat" bushing to fit the bore and machined lower surface, and a urethane "spring washer" against the cast top surface of the mounting foot.

Here's the bottom side, the delrin flange against machined surface. This goes against the cross-member cover plate.

And here's the top side, the urethane washer gets sandwiched between the cast surface of the mounting foot and the crossmember. This one was the thickest of the four feet on this rack, and provided just under 1 mm compression.

What is unknown is how the urethane holds up over time. It doesn't matter if it "takes a set", as long as it doesn't collapse. I don't think it will, and my first set has been in service now for about 6 months and about 8,000 miles.

Cheers,

__________________

Jim & Sue Corenman

--------

Here's another make from Delrin:

and another style: