Lots of musings and

thoughts being thrown on a topic which we've researched extensively. Our

research was then used to come up with the 928 Super Clamp to stop the drive

shaft pull out problem at the front flexplate which can lead to 928 engine

thrust bearing failure (TBF). I will try to keep it short and hit the high

points in order to explain this situation concisely.

1. When Porsche first devised the auto driveline they used washers, a bearing

and a circlip at the front of the older 25mm drive shaft to help set the correct

distance between the flywheel and flexplate. These parts can be seen in the work

shop manuals (WSMs). The correct distance which was to be calculated by the

mechanic in the field, would have the flexplate set a bit away from the flywheel

and when the flexplate was clamped to it, there would be a bit of rearward pull

on the flywheel.

2. Porsche learned of problems with their WSM instructions since mechanics were

not correctly setting this distance and some customer 928s were returning with

TBF. Porsche then sent out there driveline engineer on a world tour to teach

Porsche techs how to properly set this distance.

3. Sometime in 1984 Porsche stopped using the bearing, washers and circlip

arrangement at the front of the drive shaft and merely had the field techs just

clamp the front flexplate clamp as the last step after a TT change out. This

change is found in the WSMs. However the front flexplate clamp was not designed

to hold onto the drive shaft by itself.

The front bearing, washers and circlip aided in this and when they were taken

away it is our opinion Porsche should have changed the design of the front

flexplate clamp.

4. Then Porsche came out with the 85-86 32 valve 928s which saw an increase in

horsepower and torque. This further compounded the problem since the extra

torque now twisted the drive shaft even more and the front clamp could not hold

the drive shaft. Porsche started seeing a problem with this and instead of

focusing on the clamp, they instead increased the diameter of the drive shaft

from 25mm to 28mm sometime in 1987. I was told by the 928 Porsche drive line

engineer this was done to handle the increased torque. However it's interesting

that although the 5 speeds saw the same increase in torque, it's drive shaft

remained at 25mm. It is our opinion that Porsche was trying to control the drive

shaft pullout by increasing the drive shaft diameter.

5. Unfortunately this did not stop the problem of drive shaft pullout.

But it did give the 928 automatic drive line another failure point since

Porsche, keeping it's old clamp design for the 25mm drive shaft spline, had to

neck down the 28mm drive shaft back down to 25mm causing a stress riser at the

neck down point. This has caused 28mm drive shafts to shear for owners in the

field.

6. We looked at many different solutions for this problem and after testing a

few, we came up with our Super Clamp design. It is *not* the one that Theo has

shown. It is totally different and attaches at the front flexplate with no

modifications, can be used with both the 25mm and 28mm drive shafts and clamps

onto the drive shaft extremely well. This has stopped drive shaft pullout at the

front flexplate.

Hope this helps with your discussions,

Constantine

Black Sea R&D

=====

Thought this was a understood point but I guess it's still in contention.

The drive shaft twists under load and shortens. It is due to it's design as a

approximately 1 diameter inch bar which is pretty long. It's also called a "prop

shaft." This is used in other applications to include the boat industry. That's

why Porsche placed a flexpate at the flywheel to allow for this contractive

force.

The front original flexplate clamp cannot alone stop the pullout of the drive

shaft and it allows it to be pulled out a bit each time until it finds an

equilibrium point. The contractive forces are much more than the subsequent

pushing of the relaxed shaft and so gets hung up by the front flexplate clamp.

The equilibrium point is usually seen as a 2mm-4mm rebound of the flexplate back

unto the drive shaft after the front pinch bolt is loosened.

The only way this type of drive shaft will lengthen is when it deforms and just

before it fails, just like when you bend a paper clip back and forth and break

it. If you measure it just before the break it will be a bit longer. This

however is not what causes most of the found forward pressure at the front

flexplate in 928 automatics.

During our study we looked at the C-5 Corvette driveline to see what they were

using. They have a hollow large diameter tube as their drive shaft and there is

a rubber coupler between the drive shaft and flywheel which takes up rotational

stresses but not contractive forces since there are none. They also experience

TBF but due to heat expansion of their drive line. After a TT change they must

run the car up to temperature then let it cool down and reposition the running

assembly.

Last point, having any forward load unto the flexplate and ultimately the thrust

bearing is bad. It will prematurely wear the engine thrust bearing and when that

happens is any one's guess. That's why Porsche wanted *no* front load at all and

devised the initial circlip, bearing and washer affair at the front of the drive

shaft to have a slight tension pulling back on the flywheel. I have talked to

many owners who have suffered TBF, a lot more than I care to have known about.

Not everyone who owns a 928 is on Rennlist.

Cheers,

Constantine

=========

It seems very unlikely that the shaft shortens that much. 4mm flexplate offset

into engine direction means that the shaft may be shortening as much as 8 mm

before pulling out more into the transmission direction. no no... it must be

something else.

=========

A wobble in the flex plates fits the ideas I've accepted -- it would affect the

clamp at between about 10Hz and 100Hz; it would affect the forward end of the

shaft much more than the rear end; it would not involve special loads or

movement on other parts of the car; it would be addressed by a strong clamp such

as Theo's or Constantine's; and it might generate a force in one direction

(towards the flex plates, or towards the un-torqued portion of the splined

fitting) -- but I can't think of a way to verify this one.

Ray

==========

Actually I thought of a way to verify this, or something very much like it.

One problem with the test setup that is being suggested is that for the amount

of movement needed to be shown there will need to be in the millions of

revolutions. Another problem is that with the small amount of shaft that is

being suggested the amount of movement will likely be much less than in real

life mainly because of the weight of the shaft, which I think plays into the

equation.

What I did a few days ago while this discussion was going hot and heavy was set

up an experiment in my lab (shop) where I found a piece of aluminum round bar

stock about 3 and a half inches long and I drilled a hole through it long ways

to just under 3/4 inch. Then I intended to ream it to exactly 0.750 inch, but my

reamer was too big to go in my tail stock chuck on the lathe, so I put the work

piece in my mill vise and chucked the reamer in the mill and reamed the hole

there.

Unfortunately (or maybe not) the hole did not come out quite precision in that

is is centered on one end but about 3 or 4 thousandths off center at the other

end. I put it in my lathe that way and proceeded.

Next I found a piece of stainless steel heavy wall tubing about 18 inches long

that was laying there and slipped it in the hole in the "body" piece I now had

in the lathe. I put it about midway on its length in the body piece. I turned

the lathe on at about 400 rpm with the lathe turning toward me--as if making a

conventional cut of the front of the body. That was with the lathe turning

counterclockwise when viewed from the work position, just as if looking forward

at the flex plate from behind the engine, and with rotation the same as the 928

engine.

At that rate of rotation the stainless tube gravitated out of the hole in the

body piece about a half inch in about a minute. Then I reversed the rotation and

the tube gravitated back the other way into the body about the same rate.

I reversed the body piece in the lathe and did the same thing and had just about

the same result. This time however. I think I had the centered hole facing me

and I think the rate of migration back into the lathe with reverse rotation was

slower.

I was excited about that test and the results and tried to post it but I don't

think it showed up. If it did I apologize for the redundancy.

What I was looking for was evidence of a kind of force that would put endways

pressure on a rotating object such as a shaft. Oh, I forgot that I also did the

rotation test as described in part 2 at a higher speed, about 625 rpm and the

result was more pronounced.

The thing about the first test that troubled me was that with the body piece

hole being off center there was a slight but noticeable wobble to the end of the

shaft that was visible on my side, even though it seemed less pronounced when

the experiment was reversed in the lathe.

What I was perceiving was that the body piece was playing the part of the

flexplate and clamp assembly, although with no clamping, and that the tube was

the playing the part of the drive shaft and also not clamped.

Then I thought that since in the 928 it seems to be the flex plate gravitating

on the shaft rather than the shaft gravitating in the hole in the body, I should

reverse the process. So, I chucked the tube in the lathe and put the body on it

and turned it in the lathe. It didn't do much, but there was some discernable

gravitation outward, but not much when the rotation was reversed.

Of course there was much less wobble to the rotating body than to the rotating

tube when the body was chucked.

What I did next was decide that I needed to clean up my act and put a little

more precision into the test, so I first chucked my reamer in the lathe and

turned the end of it down so I could get it into the drill chuck in the lathe

tailstock. Then I drilled another piece of 2 inch aluminum round bar, this time

a little shorter, because that was what I had, and then reamed it while still in

the lathe. Then I polished the stainless steel tube with croacus cloth to be

sure it had no nicks or burrs and tried the experiment again.

This time to my surprise there was very little movement of the shaft in the body

hole when rotating CCW and almost none the other way; and this was at just about

any speed between 400 and 650 rpm. The experiment was turning very true in all

phases.

I tried also to reverse the test as before with the tube chucked and the body

floating and got essentially no migration either way on the tube in either

direction of rotation and at any speeds as before.

I was disappointed by this test experience until earlier today when one of you

put up the excellent piece about vibration. Now, when you have suggested this

similar kind of test for wobble I am beginning to think that my first sloppy

test has some validity, and more so than the more refined test.

Oh, one additional consideration I had was that perhaps the migration was

somehow related to the lathe and whether or not it was level. I found that it is

not level, but that most of the migration out of the hole was also uphill.

I think that this test or some of the results together with the discussion about

vibration could lead us in the direction of finding the answer to the problem

that so many have already solved for us, but without knowing what is causing it.

Any further ideas would be welcome.

Jerry Feather

======

From: Wally Plumley [mailto:wplumley@bellsouth.net]

Sent: zaterdag 10 oktober 2009 5:09

To: 928

Subject: [928] Re: TBF discussion

One suggestion that has been made is that the drive shaft is twisting and

shortening upon hard acceleration. This shortening is very powerful, and is

causing the driveshaft to slip back in the clamp. When the shaft has pulled

back, it then puts constant force on the thrust bearing. The force is especially

destructive during dry starts. Eventually this destroys the thrust bearing, then

the block.

I suspect that what we have here is a failure to communicate, and that the

flexplate actually moves to the rear on the shaft when released, rather than the

shaft moving to the rear.

Wally Plumley

928 Specialists

www.928gt.com

-------------

Hi Wally and others,

if you remove the clamp form the assembly that holds the TT, you see that there

was a lot of internal movement. It is easily seen on the pictures on my web. To

me it shows that there is a micro movement under the clamp, and that combined

with a pulling force makes the clamp creep. Imagine that the surface of the

clamp and the surface of the part that holds the TT constantly move a little bit

over each other when the rotating forces of the engine is applied. The metals

shift and slide, If you pull a little, the slide is into one direction, the

pulling direction. When the forces, stop there is no sliding back as the clamp

starts holding again.

At some point the forces start to balance and there is no more creeping. It

doesn't move back as there is no reverse force. If there would have been an

identical reverse force the clamp would creep back into place.

The TT is pulled out of the clamp and stays there when the clamp gets grip

again. That moves the clamp towards the engine on the TT, causing the flexplate

to bend in the engine direction. When you release the clamp bolt, the clamp

moves onto the spline into the transmission direction. The protruding spline bit

that you see gets 2-4mm shorter. (Wally said this already, just restating)

If someone thinks driving in reverse would help, that needs some explaining to

me :))

It is assumed (!) that the force pulling on the TT is caused by twisting. Also

temperature expansion has been mentioned. There is no real proof yet.

Another very good solution to this problem would be a more flexible flexplate.

We tried that and came up with a design that would work, but looking at the

strong design of our flexplate, it was not possible to keep that strength. It

failed badly in our test. Another option was make a loose coupler, basically a

rubber spider link between two fixtures. But space, difficult assembly,

durability and cost were an issue. So we came up with a proper and very strong

clamp, and that works :)

I am convinced that this is what Porsche actually intended with the original

design but failed to achieve.

My advice: take Constantines or our stronger clamp, or keep loosening the clamp

on a very regular basis. (I hate loctite to glue it in place but that works too)

To Johnny: dear friend, we agreed not to agree... right?

I will put the Porsche statment online on my web later today. Not that is any

good to anyone. It looks to me like a disclaimer.

regards

Theo

1992 928gts Midnight Blue (2006-)

1988 928s4 Cherry Red (1999-2006)

The Netherlands

http://jenniskens.livedsl.nl

http://928gts.jenniskens.eu

-----------

From: Johnny Billquist [mailto:bqt@softjar.se]

Sent: zaterdag 10 oktober 2009 10:52

To: 928

Subject: [928] Re: TBF discussion

Of course, an equal force in the other direction will also appear upon

no acceleration. So why don't that force count?

The clamp slips when you apply force in one direction, but don't slip

when you apply the same force in the other direction... Impressive.

Also, how much do you think the shaft will shorten because of this twisting?

Johnny

------------

Johnny,

We are bedating again...:)

**Assuming** the shortening of the TT because of TT-twist is the actual cause of

the pulling force, you will see that twist effect on both accelerating and

decelerating when the rear wheels drive the engine. The Accelerating force will

be stronger obviously. But there will not be a pushing force to complement the

pulling force. Now, when decelerating, the rotational forces working on the

clamp will be far less, allowing the clamp to hold by friction. No micro

movement anymore.

The clamp only moves when under serious load, that is my believe.

The TT twisting will be very small, not 2 or 4 mm I think. It is the creep

effect that makes this large relocation. There was a debate long ago about this

twist effect. Don't remember any numbers or calculations though.

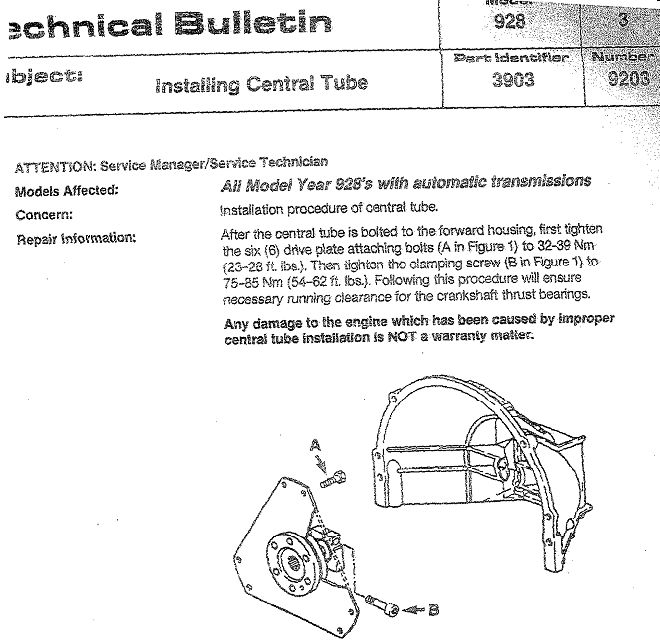

Porsche says that fixing the clamp to 85Nm and after that, fixing the flexplate

to the flywheel will cause pressure on the TBF which is not covered by warranty.

The clamp should be the last to tighten. They are absolutely right. It also

makes it hard to prove that something else caused a TBF as obviously some

mechanic must have screwed up or did not read the service bulletin at all. And

do all mechanics know all the service bulletins? Do we....?

This discussion can go on and on for ages.... I'd fix the problem without

exactly knowing the root cause.

regards

Theo

1992 928gts Midnight Blue (2006-)

1988 928s4 Cherry Red (1999-2006)

The Netherlands

http://jenniskens.livedsl.nl

http://928gts.jenniskens.eu

=======

Johnny,

Agreed, both acceleration and decelleration will cause twisting forces. I

thought it was said differently, like decell would reverse it. Obviously not.

At some point all forces are in balance if you count the friction of the clamp

in too. Yes, friction under the clamp plays an important role here.

The real question is where does that force originate from.

Think of the frictional forces like this: Imagine the clamp not from steel but

from plastic. A plastic clamp on a broomstick. At forces the steel deformes

pretty much. If you twist the plastic clamp with force, and pull out the stick

with a axial force, you will see tiny movements every time you do that. Turning

forward/reverse is a good practice to remove the plastic clamp from a stick. The

clamp moves bit by bit until it is off. Just pulling would not do it.

Did you notice this:

http://jenniskens.livedsl.nl/Technical/Tips/Pics/TT%20clamb%202886.jpg

Look at the movement marks. I did not do this. These are traces of internal

movement under the clamp. The whole thing twists and deforms under load.

Imagine this, please follow the thought:

- we start at zero pre-load

- we drive and for some reason the TT shortens (assume, we know there is a

force), pulls on the clamp

- the flexplate bends to the rear

- we pull harder

- the rotational forces cause micro movements under the clamp, and the TT is

pulled out a 1mm

- the rotational forces stop, and the system goes in rest.

- the clamp does not move but holds since the cause of loosing grip is gone

(rotational)

- the flexplate is now 1mm pushed towards the engine (TT back to normal)

- next time we drive the TT pulls again, but needs to compensate the 1mm preload

- it needs to shorten 1 mm to reach the zero preload point

- TT shortening pull continues and forces reach a point where the clamp slips

again, lets say 1mm extra

- rotational forces stop and the system settles again, but now at a pre-load of

2mm

- the force from the flexplate is less that the friction force that holds the

clamp on the TT

- the flexplate is now bent 2mm into the engine direction. Without rotational

force the clamp holds that position

- and so on. The max movement I heard is about 4mm.

- maybe at some point the the flexplate makes the clamp move back a little until

forces reach a equilibrium, who knows

Imagine shortenening of the TT of lets say 5mm. That seems like extreme to me.

One other option is that the crank itself causes this, basically moving the

flexplate. It would pull the flexplate towards the engine. I don't see that

happen and the crank play is just 0.2mm or so. One more option is the thermal

effects, where the expansion of the tube is different than the expansion of the

central shaft. But 5mm?

So.... So I'm still puzzled. I'm an electronics engineer, mechanical is not my

game.

Anyway, my big concern is that 2 or 4mm pre-load on the flexplate is achieved at

300-500kg force. And this is so much that you canít expect the flimsy thrust

bearing to cope with it. But worst is that this is not a momentary force, but a

structural one that is at its highest point when the engine is not under load,

and it decreases as the engine is under heavy load. Even reverses direction I

think. The severe load is when the engine is poorly lubricated, just after

starting. That is why all those thrust bearing failures happen. Not because some

lunatic tightens the rear TT clamp, front TT clamp and then starts to bolt down

the tranny by pushing it into position. Same goes for putting in the engine,

causing stress on the flexplate when bolting it down to the flywheel, thus

pulling things together with M10 bolts. Porsche makes it very clear that there

should be a stress-free situation when bolting down the clamp.

In my opinion, and you don't have to agree, it would be best to have either a

sliding clamp at the flexplate, a better flexplate that absorbs the 5mm or....

Or.. a clamp that at least prevents a structural preload when there is no severe

pull from the central shaft. The better clamp makes it a momentary force at a

point when the engine is lubricated at its best (hot thin oil under pressure at

higher rpm's) and settles back at zero pre-load when shut down.

And by far: Porsche said themselves not to have any stress in the central shaft

when tightening the clamp. This preload is what they said *not* to have and

repairs resulting from ignoring the procedure will not be under warranty. So if

you still think it is ok to have flexplate pre-load you must think again :)

Damn long story, I know, it also helps making up my own mind :)

Ok, lets rest his issue until a *new* bright idea pops up.

regards

Theo

1992 928gts Midnight Blue (2006->)

1988 928s4 Cherry Red (1999-2006)

The Netherlands

http://www.jenniskens.eu

http://928gts.jenniskens.eu