Lifters apart!!!!

Here is the key. Tap the lifter on its edge to remove as much oil as you can and

at the same time pump the button with a magnet. It will act as a pump shooting

oil out the inlet hole.

Once you think all the oil is out (which it will not be) , the button should

move freely (but with no spring) Push the button in all the way and then bang

(very hard) the open end of the lifter down flat on a table using a couple of

ply of shop towel or something as cushion. Then look at the button. It should be

very extended or almost out (if it didn't fall out) Once you see it extended

(may take a couple of bangs, and be sure the button is pushed all the way in

before you bang the table) then you can easily pull it on out with your pliers.

Once out:

Release the oil pressure behind the little ball by using a pick to push the ball

a little (check its action) and at the same time squeeze the piston together

with your fingers and you will get a shot of oil from the balls hole. Then its

free and guess what "There is now very nice spring action.

After I cleaned the parts per Bill's post above, reinstalled the piston (very

easy, just slide it back in) the button acted as it should with very nice

spring.

I am now working my way checking all the lifters.

__________________

David Lutz

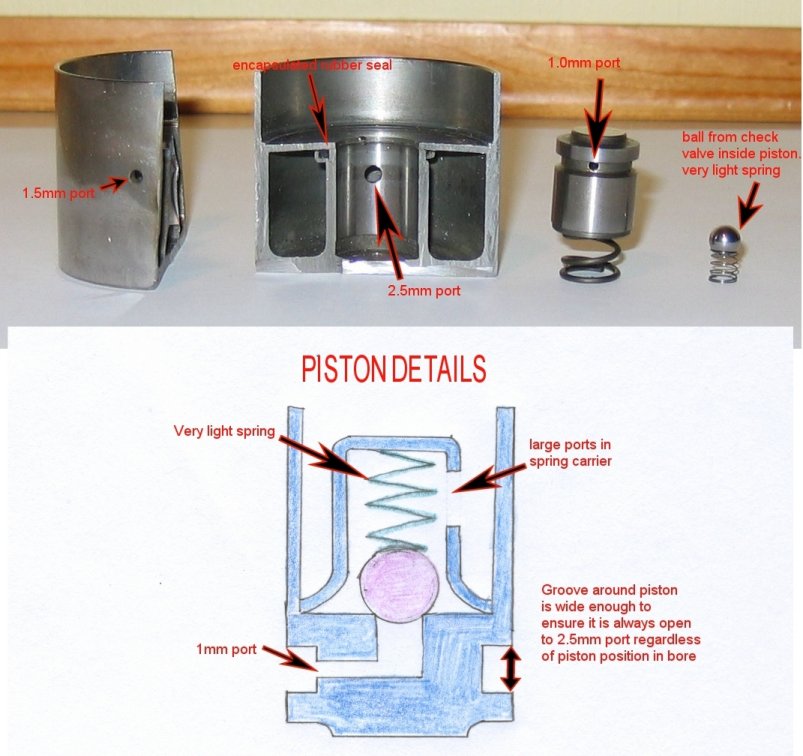

The problem is the 38mm 16V lifters which are difficult to disassemble for

cleaning.

The 38mm lifters are also extremely expensive.

The 35mm lifters for the 32V engines are easy to disassemble and clean and much

cheaper to buy.

Åke

====