The actual cause of the 2/6 bearing failure has been discussed many times. Many believe that 2/6 oil starvation is the real cause. Some possible root-causes:

1- low on oil. Bad thing obviously.

2- extreme cornering at high speed and high rpm of driving up/down hill at serious inclinations. This makes the engine draw air and compress the air in the oil galleys of the lower block. The 2/6 is closest to the pump and is the first to be hit with compressed air. That is not a good idea at 5000rpm or more.

3- foaming of the oil and subsequently picking up air in the oil path causing the problem as in #2. Especially the low viscosity oils like 0w30 are a bad idea. The engine is made in the mid 70's and not changed much after that. It takes 20w40 or 15w50 to run on. Maybe go for the 10w60 oils. It is a fact that low viscosity oils tend to foam a lot more than the thicker oils. The foam is the killer for the 2/6 bearings.

--------------

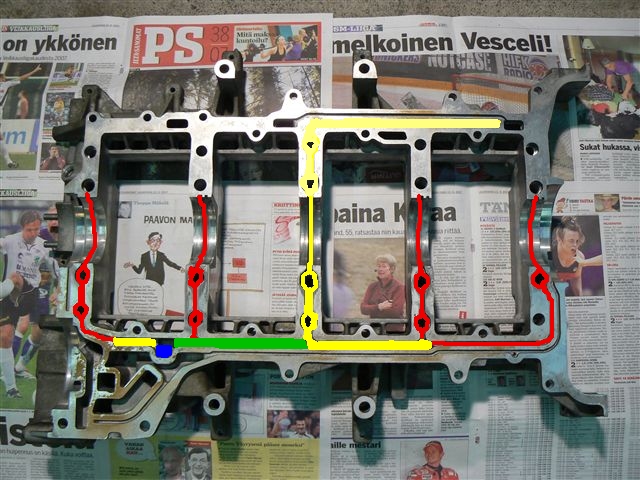

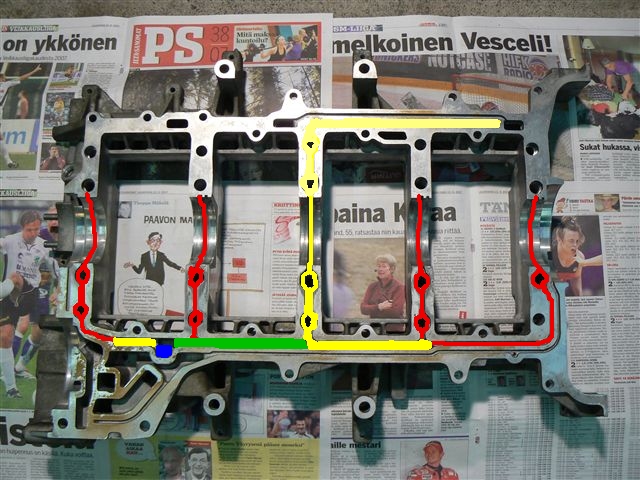

(Picture by Erkka Vilhunen)

___________

I lifted these pictures from Rennlist a little bit ago.

Hope this helps visualize the cross drilling.

The attached picture shows the short path to the main bearing that feeds the 2/6

rod bearings. (highlighted by the red cord)

As we can see the first gulp of air/oil-foam arrives here first.

Ed

___________

Oiling facts:

1 during a test at laguna in 1995/96, using mobil 1 at factory recommended fill

volume, turning 1:44's laps, showed repeated fluctuations - drops in oil

pressure using a stock crank running at 6000 rpm.

2 dyno test to 8,000 rpm for 30 seconds using a stock crank and modified chipset

using factory filled crankcase showed fluctuations in oil pressure at 3-6

seconds

3 disassembly of the above engine showed unusual wear patterns on 2/6 rod

bearings vs other journals. all journals had "rpm" related wear

4 same laguna test #1 performed with drilled crank.. same oil pressure drops

5 same test as #2 performed, same drops

engine not disassembled, oil tested ok

6 install devek race accusump system

7 #1 laguna test performed, no oil fluctuations

8 # 2 test performed again, oil fluctuations occurred later in test 10-14

seconds

9 engine disassembled and bearing checked....some wear on 2/6 bearings

10 two known 2/6 rod failures in GT by driving at or above 5500 rpm for over 100

miles through sweepers. engine oil level unknown.

11 many 2/6 rod failures in track driven 928s

12 known failures using an accusump...one not turned on and the others not

installed correctly and too small a capacity...now you know why we choose the 3

qt vs a smaller size.!

13 Porsche AG purchased DEVEK race level accusump for 928 racers after repeated

failures of customers racers....no recorded failures since installation

Conclusion:

2/6 failure at normal rpms is due to oil starvation, not crank oiling pattern

the hotter the oil, the faster the onset of starvation

if you are spinning it ot over 7K rpm, drill the crank

DEVEK 3 qt accusump system will allow for more time before onset of oil

starvation. If you are using slicks, use the race level system.....

dry sump will eliminate starvation forever, regardless of crank, unless you

exceed 7000 or so rpm, then you need revised oiling pattern...also, a well

designed dry sump will add 7 or so hp per liter...hmm, in a 6.5 that makes close

to 50 hp...

Porsche designed an excellent street engine......the reason why GT and GTS fail

"more" often is the average revs are higher, thus more oil is pumped and

"aerated", and less is available to be pumped to the bearings.......And in

Germany, running at 170 ish on the bahn, the revs are high, the oil level in the

crankcase is low and up comes a high speed high "g" corner...and a potential oil

starvation situation.....a condition they did not take into account.....well

enough.

Things you can do to minimize the situation:

1 keep the oil cool

2 run high grade synthetic...cost more, but change less... amsoil, redline, etc.

3 if racing, use race level accusump

4 if building a racer from scratch, use dry sump and gain hp

maybe more on crankcase venting later...

Marc

DEVEK

__________

Blue = 15mm wide round feed pipe from oil filter = 177mm^2

Green = 8.5mm wide x 16mm deep = 136mm^2

Yellow = 8.5mm wide x 10mm deep = 85mm^2

Light yellow = 7.5mm wide x 11 deep = 83mm^2

Red = 5mm wide x 5 mm deep = 25mm^2

=========

The theory about oil galley changes is like this:

1. It is assumed that oil contains air, which is foaming due

to piston blow by and lots of internal movements.

2. The air does not get evenly spread on all rod bearings, but especially hits

the 2/6 bearing. More air reaches this bearing compared to the other bearings.

Explanation to the picture of Erkka:

At the blue dot, the oil reaches the oil galley of the lower block. Both front

bearings apply to piston rod 1/5 and 2/6, the middle is for the cylinder head,

the both rear are for the 3/7 and 4/8 bearing.

As one can see the oil feed for the rod bearing 1/5 and 4/8 is at the end of the

supply line. All that reaches this point is fed into the bearing. Problematic

are the branches at the 2 and 4 main bearings. Both make a 90 degree turn

form the main path, and it is likely that a separation of oil and air takes

place. The heavy oil will likely follow the main path and air will escape the

other 90 degrees branched route. This is normal behavior based on fluid

dynamics.

At bearing 4. the branch is a smaller size route from the main oil galley (switch

Yellow->Red = 85mm^2 -> 25mm^2). The oil is pressed a little into

the oil path due to the diameter change, and turning into the branched path is

favored. The same is at the middle bearing which is used to supply oil to the

heads.

Now, at the branch to the 2. rod bearing the main oil routs is not changed

in diameter. The fast flow of oil will not have a tendency to flow in the

branched route, but flow dynamics says it will try to flow onwards in the

straight line. This makes it the idea oil-air separator. The air will enter the

2. bearing branch and the oil flows to the rear part of the engine.

Effectively, if this air pocket happens under high load and

rpm and lasts just a little, it is likely to destroy the main bearing, and very

possible break the rod. I've seen rods broken or sticking out of the block

itself.

Sören