Originating from Rennlist:

Anyone defeat portions of the bulb control module? I've been wanting to

defeat the third brake light so I can replace it with an LED.

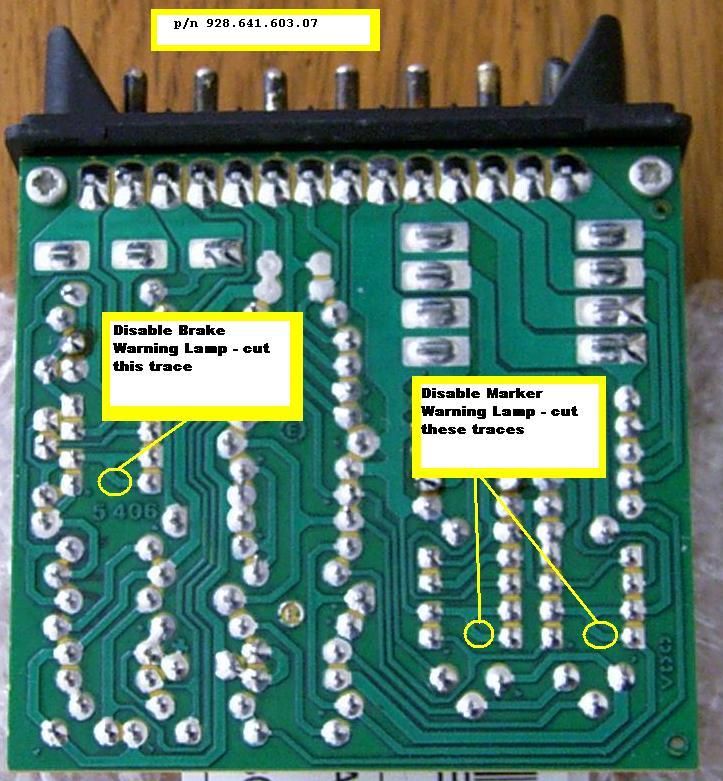

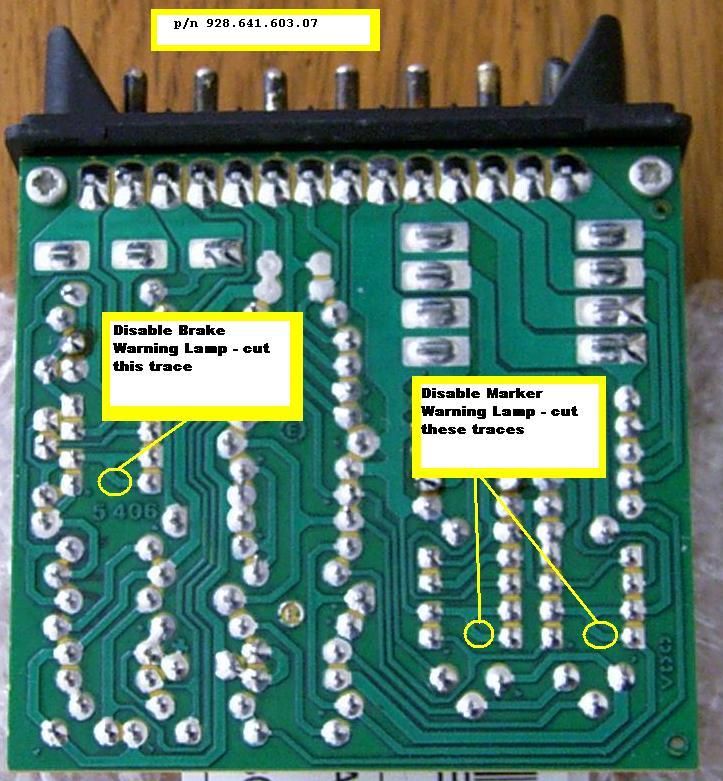

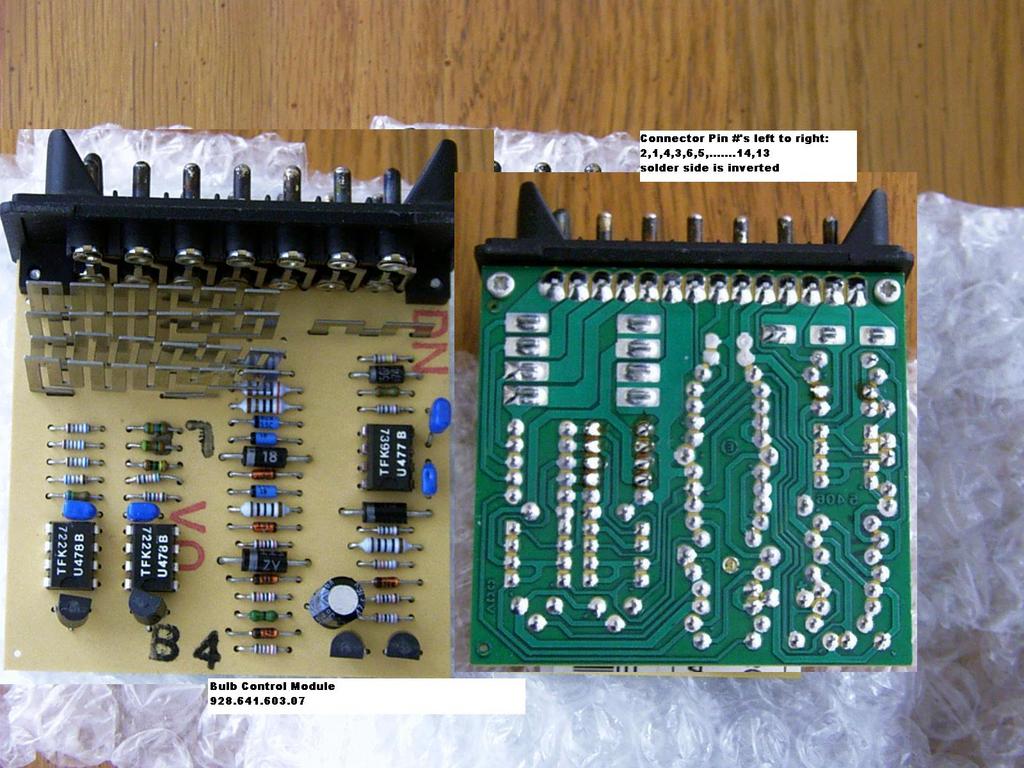

I've got a spare bulb control module (p/n 928.641.603.07). Took off the cover.

Looks pretty simple. Automotive application IC's. Found a datasheet on a similar

bulb control IC. Here's the photo of the circuit board:

I pasted the inverted solder side next to the component side. You can see the

sheet metal shunt resistors. The circuit basically measures the voltage drop, in

milivolts, across these shunt resistors. The shunt resistors are in series with

the incandesant bulbs. Marker and brake lights are the only bulbs that are

monitored by this unit.

borland

90' S4

_________

Borland & Ed - just swapping the load resistors should be enough. The lamp

control module just senses that the voltage drop across the resistor when the

load is turned on is enough to indicate the bulb is not burned out (and

presumably also is not so much you have too powerful of a bulb installed).

So there is a voltage window comparator... however its configured.

So a higher value Rx should work - you'd need some trial & error to determine

but a ratio of the Bulb Current: LED Current should be close to the Needed Rx

value: Existing Load Rx value. You will not need anything like such a high power

load Rx - 2W ceramic should be perfectly OK for a typical LED bulb (but maybe

not for a 3W LED version).

Another way to do this is to monitor the voltage across the load Rx's when the

correct bulbs are active - then match that voltage drop for your LED's

Alan

__________________

I see from the data sheets that the threshold voltages are 53 mV for the U4791B

and 8 mV for the U4790B; that's the main thing I wanted to know. Now it's just a

matter of a few details like what shunts are hooked to what bulb sockets, what

LEDs we're using and their current flow at normal voltage, a little math, some

adjusted shunts, and Bob's your uncle.

BTW, borland, thanks for taking the time to pull your module and get the IC

info. It's nice having the right data sheets for the ICs used in our 90s.

__________________

I'm finished with the mod and experimenting...

To verify cutting the traces defeats the bulb monitoring, I cut the traces for

the Marker Lights. It does disable the digital instrument cluster's "Tail Lamp

Failure" message. On the cars with digital display, you have to start the engine

and wait for the digital display message. Headlights or parking lights need to

also be turned on also.

Later, I also cut the trace for the brake light and verified the same defeat for

the Brake Lights monitoring.

Restoring the traces is easy if you keep the cuts narrow. All you need do is to

tin the copper plating on both sides of the open trace, de-flux the cut area

with a solvent, and then apply a drop of solder from the soldering iron. The

trace will wick off enough solder to bridge the gap. Confirm the joint is

restored with a ohmmeter.

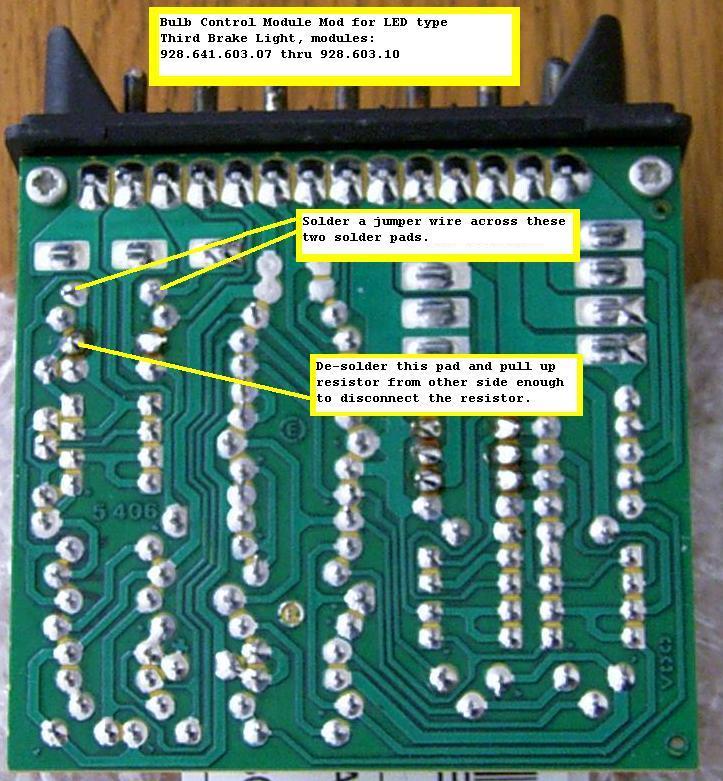

I also modified my module to allow an LED replacement bulb for the Third Brake

Light. It works great; no faulty warning message. With this mod, if the other

incandescing brake light bulbs fail, the warning feature will still work. If the

LED fails alone (>10,000 hour typical life, so highly unlikely), then no

warning.

Hereís an annotated photo describing the LED Third Brake Light circuit board

mod:

Iím not recommending anyone do this to anyone's car, as it defeats the carís

original design safety features. Just documenting what I did and the results.

________

Pulled the module on my 90' S4.

Quite easy to do on the 90' and later cars. The module resides just to the

outboard side of the glove box. Simply remove a triangle shaped carpeted piece

(three screws), open the glove box door and remove a couple more nuts that hold

a bracket in place, and the module drops down along with a alarm module.

The module on my 90' has a later part number, # 928.641.603.10. Taking the cover

off.....

- same printed circuit board as in the photo previously posted,

- same component count. Only difference is the ICs are of a different part

number.

- uses Telefunken U4791B and 4790B special automotive application ICs.

So, different part number but same basic circuit.

borland

90' S4

Here's are datasheets of those chips:

U4790B datasheet.pdf U4791B datasheet.pdf U477b Connection Diagram.pdf

------

Hello Dan,

The bulb monitoring is built on a small valued resistor (wire) over which the

voltage is measured, and if it exceeds a certain margin the alarm is sounded. So

yes: it measures current in the independent bulb chains. It is compensated for

the PTC effect of the bulb filament. This might be useful to you:

http://jenniskens.livedsl.nl/Technical/Tips/7/MyTip752.htm I even got

the datasheets of the comparators :) Reminds me I must put the U477B/U478B on

line as well. The U477B is 16mV, the U478B is 100mV.

Since the current is rather high, you're looking at a low shunt resistor of

milli Ohms. So any contact problem at both alarm unit as bulbs themselves will

cause a warning.

12v battery, 5W bulb, 5/12=0.417A, trigger is 100mV, so shunt resistance for a

5W is about 240mOhm. Not much.

I'm not really sure but it looks like they hooked up brake lights on two

comparator inputs on 477 (54L/#13 and 54R/#11) and the tail lights with side

markers on 4 separate chains using two dual 478 (58R #3/#4 and 58L #1/#2). There

are two separate warnings: #7 reports a brakelight warning, #10 reports a

taillight/sidemarker warning

The blinker is not wired to the bulb controller box, but it shares the ground

connection. If that one also has problems (slow blink) you're on to bad grounds

or bad power.

So....you probably have a ground contact issue, wrong/bad bulbs, low on 12v

power for the bulbs (when lit), or a defective warning box.

Oh, and don't forget to check the front and side marker bulbs. They add to the

current.

regards

Theo

1992 Porsche 928 GTS Midnight blue

The Netherlands

http://jenniskens.livedsl.nl

http://928gts.jenniskens.eu