Total data overview from various compressors: Compressors data.pdf

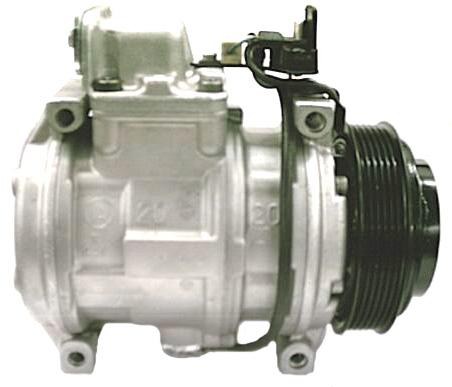

1992 928GTS compressor

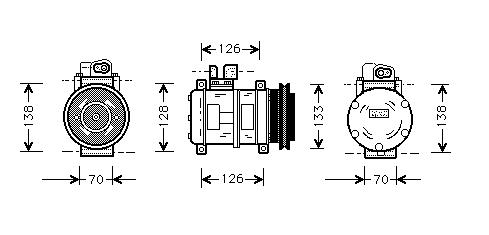

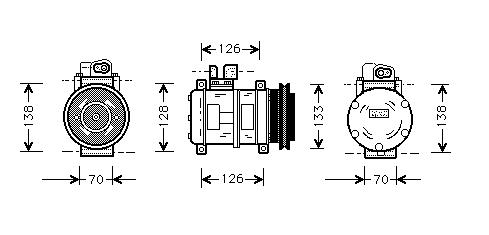

Kompressor, Klimaanlage PORSCHE 928

Artikel-Nr.: G945476/13178

OE-Vergleichsnummer: PORSCHE: 92812611301,

PORSCHE 928 5.4 GTS

ab Baujahr : 07.1992

Producer: DENSO

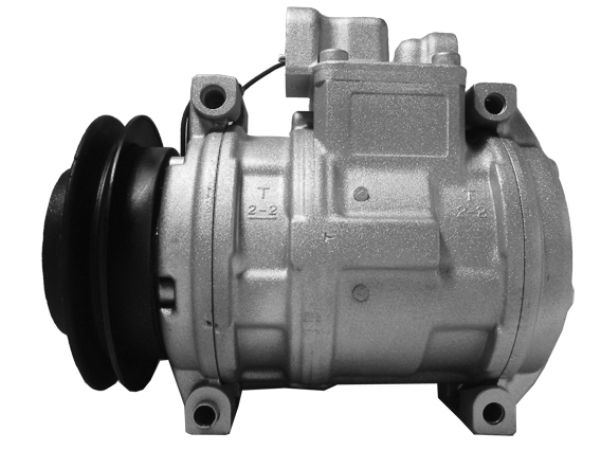

Compressor-ID: 10PA20C

Compressor oil: PAG 46

Oil volume: 210 ml

Clutch: with belt pickup

Belt disk-Ø: 126 mm

Belt Ribs: 1

Voltage: 12 V

Fits: 928GTS

=============

http://www.acsource.net/xcart/home.php

http://www.pelicanparts.com/techarticles/911_Nippondenso_rebuild/911_Nippondenso_rebuild.htm

1992-1995 928GTS

SKU: Compressor for 1992 Porsche 928 (5.4 V8 Gas FI)

Nipp; 10P15E

6 Gv .570 X 4.92; 4 Ear

SKU: 127489-P/N: 902-027

1991 928s4/gt

SKU: Compressor for 1991 Porsche 928 (5.0 V8 Gas FI)

Nipp; 6E171

1 Gv.7 X 6.0; 6 Ear

SKU: 127475-P/N: 15285

1985-1990 928s4/gt

SKU: Compressor for 1990 Porsche 928 (5.0 V8 Gas FI)

Denso; 6E171

1 Gv; 5 Ear Mt

SKU: 127467-P/N: 471-0122

The correct oil filling of the Porsche used AC compressors:

The compressor is a Nippondenso 10PA20C (Porsche P/N 928.126.113X) used on the

'90 and '91 only.

http://www.acsource.com/index.asp?PageAction=VIEWPROD&ProdID=394

http://www.acsource.com/index.asp?PageAction=VIEWPROD&ProdID=100

I fix these in the uk. We are only allowed 134a so that's it, but I get 100%

success. Your problem is knowing where the leak is - I use a special gas and

overpressure with N2 then use a sniffer. Excellent results but a lot of kit for

a one off. The dye is crap and will only tell you if you have a big leak, it

gets everywhere and really pisses me off. Don't go there. If you want to pretty

well guarantee a leak free system, you have to change the condenser, hoses,

rebuild compressor, new expansion valve and new filter dryer. If you do all of

that you have magically replaced all the 'o' rings too. The evaporators (in the

cabin) rarely go, but if they do its a complete dash out job.

Most common leak points are the condenser mounting area (the bolt frets the

bottom of the matrix and eventually wears through. No notice, but dramati, the

metal to metal joint on the suction hose (engine side of the rad), the expansion

valve adjustment 'o'ring on the later valves (S4) and the compressor seals. Seal

kits are quite cheap and it is not rocket science, but dismantle the swash plate

over a sucepan as ball bearings will fly everywhere. All the parts are available

from SunAir. Very early 928s ('79 - 81)had Bosch/Behr compressors. Actually very

good, but difficult to get bits for and very heavy. S,S2 and S4 up to '90/'91

use Denso 6E171, and '91-on use Denso 10PA20C. The 6E has 3 pistons, the 10PA

has 5 and is lighter, and the hoses are almost twice the price and only

available from Porsche - unless anyone else can tell me differently.

Re-gassing should be done by someone who understands the system as they are all

slightly different, and although I start by putting a weight of gas in, the

final adjustments are by experience. Don't ask me why, but thats the way it is.

I have done about 25-30 systems now.

Richard

You most likely have a Nippondenso brand 6E171 model compressor.

A one day total leak down is a significant leak that usually can be found.

You could do a simple inspection for the common leaks in the 928, starting with

the high side hose (compressor to condenser) looking for signs of dirt

collecting in the oil that may have been pushed out with the refrigerant; check

closely where the hose is crimped (ferrules) to hose end fittings. Next, as Zeus

suggested, consider a nose seal leak by looking again for dirt and oil

accumulation around the clutch/pulley. The next suspect on a single evaporator

shark is the expansion valve, however start your inspection at the drier and

check for the rubber hose joint in this metal line prior to the expansion valve.

When you get to the valve you are checking the inlet line port and also bellow

“cap” on the valve; which we have found to be suspect at times.

If you have a friend nearby that has either dye & light detection tools or a

refrigerant electronic sniffer this would be your next avenue to finding the

leak. You could drop in a can of R134a and check out and sniff the system

components and joints. Otherwise the last step is to simply pay a tech to find

the leak and give you quote to repair.

If the source of the leak is the compressor, the 6E171, if not worn out

(pistons, wobble plate, ball and shoes), is not too difficult to reseal. You can

simply zip off the shaft nut in front of the clutch with an air gun, remove the

clutch assembly with common snap ring pliers (watch the shims for setting the

air gap in the clutch), tap out the key out of the shaft, remove the compressor

assembly bolts with a 6 mm allen hex. They most likely will be residual ac

refrigerant oil hiding in a cavity or two in the compressor. Before you clean it

out inspect the oil using magnification to check for signs of metal

contamination. If you find any they you most definitely want to liquid flush the

lines, condenser and evaporator.

You’ll be replacing the front nose o-ring, center case halve o-ring, rear head

o-ring and shaft seal, front and rear reed plate gaskets (if the compressor has

not been resealed before then most likely these gaskets will be bonded to the

reed plates; get some liquid gasket remover and be careful not scratch the

mating surfaces on the nose and head. If the reed valves are pitted, corroded or

rusted you’ll have to think about replacing them (not usually included in retail

“seal kits”) if you can’t clean them up. The rusting or pitting is related to

moisture in R12 systems.

Inspect your shaft where the nose seal makes contact with it. If it is rusted

and depending upon how much pitting is present you maybe or may not be able to

salvage the shaft. When you replace the shaft seal assembly note the orientation

of the flats on seal assembly with respect to the flats on the shaft.

When you split the center section try to keep the shaft and pistons in either

side or they will fall apart and leave you pondering for awhile, so keep the

shaft with pistons on either side. Check the piston rings and the cylinder bores

for wear, though not common a 6E171. Inspect the ball and shoes on the wobble

plate as well as the wobble plate for excessive wear, again these items as not

included in the typical retail seal kits.

The 6mm hex head assembly bolts are torque’d to 18 ft lbs. The air gap for the

clutch should be checked, .020-.030" works nicely however you could stretch it

to .040".

Overall you can reseal a 6E171 without dedicated tools if you take your time.

You’ll need to add refrigerant oil to the system and usually 6-8 oz works fine.

Depending upon how old the drier is, what refrigerant oil you are using, signs

of contamination, etc. you will probably want to replace the drier for good

measure since you are going through all this effort.

When its time to charge the system, again you need equipment or a friend to work

with you if they have it, otherwise just take it to your favorite ac tech (don’t

forget to tell the tech how much oil you may or maynot have put back in the

system). Evacuation times vary depending upon the system capacity, altitude and

ambient air temp, however since you got all the time in the world I would

suggest 1-2 hours. If you are converting to R134a or sticking with it, the

general rule of thumb is about 85% of the original system weight of R12. However

the final amount or adjustment is based on P&T (pressures and temperatures

chart).

You may find some places on the net that sell seal kits out there and you may

find a few posts here and there on the 6E171 R&R (alike model was used the 944

and the old Lincoln’s).

The two primary rubber hoses on a shark single evaporator system are the

compressor and to condenser and compressor to evap pipe. I believe there is a

short section of rubber hose in the drier to expansion valve however this does

not leak often.

Griffiths