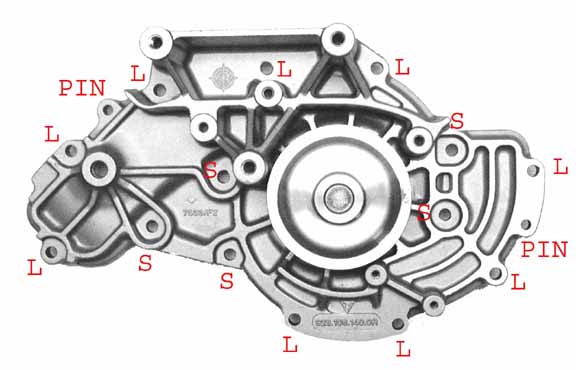

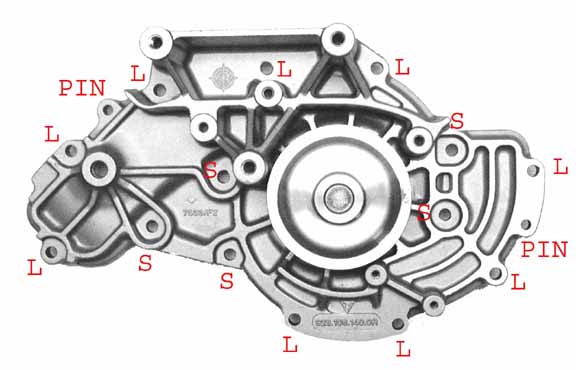

Water pump on s4 GT and GTS models

Water pump mounting holes layout.

The pump takes two sizes of bolts: 9x L(ong) and 5x S(hort).

** be aware PET says 8 long ones for both coolant pump

types. I'm unsure if/when things changed, but PET is right !!

My 928 is a 1992 GTS, and the pump should not have a bolt fixing the pump in the position just below the right side pin location. That should remain open and when attaching the lower cover, a bolt goes through the cover and attaches the pump.

If you fail to this correctly, you end up positioning the lower cover without a good fit. The Protruding stud at the cover hits the top of the wrongly placed bolt and this it does not settle properly. Btw, also keep the middle bolt of the coolant pump top-bracket out. That one also goes through the cover!

The Long is M6x25, 8.8 grade Zinc plated or Cadmium if possible (10.9 or 12.9 is harder, has more strength in the length direction, but wont like any force sideways) . The 8.8 takes a Torque of 9.5Nm (where the 12.9 grade takes 16.4)

The Short is M6x20 (see comment above)

All bolts ate fitted with a washer !!

Use Optimoly TA on the bolts, and clean the holes with a proper M6 tap (thread chasing) carefully. Make sure you -follow- the thread and not make a new one :)

Some say: use stainless steel bolts, but this is not a splendid idea. The bolts have less strength compared to carbon steel. Corrosion on the threads is the biggest problem and antiseize is a lot better than nothing, but if the bolts do get stuck you really need a strong bolt to work with :)

Theo

====

Lecture on bolts:

"Strength" of a material can have many meanings, like the proverbial story of

Eskimos having 43 words for snow.

One meaning is stiffness, the "spring rate" of a material, also known as

modulus; there are even several variations of that property, Young's modulus,

bulk modulus, etc. The interesting thing about this property is that all carbon

steels have the same stiffness, for all practical purposes. While acting only as

a very stiff spring in the form of a bolt or other component, they all have the

same level of this sort of "strength". Aluminum has one-third this sort of

"strength". Stainless steel is a bit weaker than carbon steel. Carbon fiber

composites are much stiffer. Many things turn out to be stiffness-limited, so

this property is often more important than the sorts of strength that govern

outright failures (such as ultimate tensile strength). Not bolts, usually, but

stiffness is a factor - torquing a bolt is the same as applying a spring

preload.

Curt Austin

===