www.aircondition.com

Today, as we drive our automobiles, a great many of us, can enjoy the same comfort levels that we are accustomed to at home and at work. With the push of a button or the slide of a lever, we make the seamless transition from heating to cooling and back again without ever wondering how this change occurs. That is, unless something goes awry.

(Article Continues below)

Since the advent of the automotive air conditioning system in the 1940's, many things have undergone extensive change. Improvements, such as computerized automatic temperature control (which allow you to set the desired temperature and have the system adjust automatically) and improvements to overall durability, have added complexity to today's modern air conditioning system. Unfortunately, the days of "do-it-yourself" repair to these systems, is almost a thing of the past.

To add to the complications, we now have tough environmental regulations that govern the very simplest of tasks, such as recharging the system with refrigerant R12 commonly referred to as FreonŽ (Freon is the trade name for the refrigerant R-12, that was manufactured by DuPont). Extensive scientific studies have proven the damaging effects of this refrigerant to our ozone layer, and its manufacture has been banned by the U.S. and many other countries that have joined together to sign the Montreal Protocol, a landmark agreement that was introduced in the 1980's to limit the production and use of chemicals known to deplete the ozone layer.

Now more than ever, your auto mechanic is at the mercy of this new environmental legislation. Not only is he required to be certified to purchase refrigerant and repair your air conditioner, his shop must also incur the cost of purchasing expensive dedicated equipment that insures the capture of these ozone depleting chemicals, should the system be opened up for repair. Simply put, if your mechanic has to spend more to repair your vehicle - he will have to charge you more. Basic knowledge of your air conditioning system is important, as this will allow you to make a more informed decision on your repair options.

Should a major problem arise from your air conditioner, you may encounter new terminology. Words like "retrofit" and "alternative refrigerant" are now in your mechanics glossary. You may be given an option of "retrofitting", as opposed to merely repairing and recharging with Freon. Retrofitting involves making the necessary changes to your system, which will allow it to use the new industry accepted, "environmentally friendly" refrigerant, R-134a. This new refrigerant has a higher operating pressure, therefore, your system, dependant on age, may require larger or more robust parts to counter its inherent high pressure characteristics. This, in some cases, will add significantly to the final cost of the repair. And if not performed properly, may reduce cooling efficiency which equates to higher operating costs and reduced comfort.

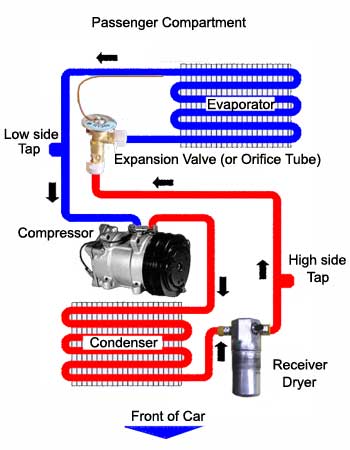

Vehicles are found to have primarily three different types of air conditioning systems. While each of the three types differ, the concept and design are very similar to one another. The most common components which make up these automotive systems are the following:

COMPRESSOR, CONDENSER, EVAPORATOR, ORIFICE TUBE, THERMAL EXPANSION VALVE , RECEIVER-DRIER, ACCUMULATOR. Note: if your car has an Orifice tube, it will not have a Thermal Expansion Valve as these two devices serve the same purpose. Also, you will either have a Receiver-Dryer or an Accumulator, but not both.

For more information on Air Conditioning, check out The Automotive Air Conditioning Information Server

COMPRESSOR

Commonly referred to as the heart of the system, the compressor is a belt driven pump that is fastened to the engine. It is responsible for compressing and transferring refrigerant gas.

The A/C system is split into two sides, a high pressure side and a low pressure side; defined as discharge and suction. Since the compressor is basically a pump, it must have an intake side and a discharge side. The intake, or suction side, draws in refrigerant gas from the outlet of the evaporator. In some cases it does this via the accumulator.

Once the refrigerant is drawn into the suction side, it is compressed and sent to the condenser, where it can then transfer the heat that is absorbed from the inside of the vehicle.

CONDENSER

This is the area in which heat dissipation occurs. The condenser, in many cases, will have much the same appearance as the radiator in you car as the two have very similar functions. The condenser is designed to radiate heat. Its location is usually in front of the radiator, but in some cases, due to aerodynamic improvements to the body of a vehicle, its location may differ. Condensers must have good air flow anytime the system is in operation. On rear wheel drive vehicles, this is usually accomplished by taking advantage of your existing engine's cooling fan. On front wheel drive vehicles, condenser air flow is supplemented with one or more electric cooling fan(s).

As hot compressed gasses are introduced into the top of the condenser, they are cooled off. As the gas cools, it condenses and exits the bottom of the condenser as a high pressure liquid.

.

EVAPORATOR

Located inside the vehicle, the evaporator serves as the heat absorption component. The evaporator provides several functions. Its primary duty is to remove heat from the inside of your vehicle. A secondary benefit is dehumidification. As warmer air travels through the aluminum fins of the cooler evaporator coil, the moisture contained in the air condenses on its surface. Dust and pollen passing through stick to its wet surfaces and drain off to the outside. On humid days you may have seen this as water dripping from the bottom of your vehicle. Rest assured this is perfectly normal.

The ideal temperature of the evaporator is 32° Fahrenheit or 0° Celsius. Refrigerant enters the bottom of the evaporator as a low pressure liquid. The warm air passing through the evaporator fins causes the refrigerant to boil (refrigerants have very low boiling points). As the refrigerant begins to boil, it can absorb large amounts of heat. This heat is then carried off with the refrigerant to the outside of the vehicle. Several other components work in conjunction with the evaporator. As mentioned above, the ideal temperature for an evaporator coil is 32° F. Temperature and pressure regulating devices must be used to control its temperature. While there are many variations of devices used, their main functions are the same; keeping pressure in the evaporator low and keeping the evaporator from freezing; A frozen evaporator coil will not absorb as much heat.

PRESSURE REGULATING DEVICES

Controlling the evaporator temperature can be accomplished by controlling refrigerant pressure and flow into the evaporator. Many variations of pressure regulators have been introduced since the 1940's. Listed below, are the most commonly found.

ORIFICE TUBE

The orifice tube, probably the most commonly used, can be found in most GM and Ford models. It is located in the inlet tube of the evaporator, or in the liquid line, somewhere between the outlet of the condenser and the inlet of the evaporator. This point can be found in a properly functioning system by locating the area between the outlet of the condenser and the inlet of the evaporator that suddenly makes the change from hot to cold. You should then see small dimples placed in the line that keep the orifice tube from moving. Most of the orifice tubes in use today measure approximately three inches in length and consist of a small brass tube, surrounded by plastic, and covered with a filter screen at each end. It is not uncommon for these tubes to become clogged with small debris. While inexpensive, usually between three to five dollars, the labor to replace one involves recovering the refrigerant, opening the system up, replacing the orifice tube, evacuating and then recharging. With this in mind, it might make sense to install a larger pre filter in front of the orifice tube to minimize the risk of of this problem reoccurring. Some Ford models have a permanently affixed orifice tube in the liquid line. These can be cut out and replaced with a combination filter/orifice assembly.

THERMAL EXPANSION VALVE

Another common refrigerant regulator is the thermal expansion valve, or TXV. Commonly used on import and aftermarket systems. This type of valve can sense both temperature and pressure, and is very efficient at regulating refrigerant flow to the evaporator. Several variations of this valve are commonly found. Another example of a thermal expansion valve is Chrysler's "H block" type. This type of valve is usually located at the firewall, between the evaporator inlet and outlet tubes and the liquid and suction lines. These types of valves, although efficient, have some disadvantages over orifice tube systems. Like orifice tubes these valves can become clogged with debris, but also have small moving parts that may stick and malfunction due to corrosion.

RECEIVER-DRIER

The receiver-drier is used on the high side of systems that use a thermal expansion valve. This type of metering valve requires liquid refrigerant. To ensure that the valve gets liquid refrigerant, a receiver is used. The primary function of the receiver-drier is to separate gas and liquid. The secondary purpose is to remove moisture and filter out dirt. The receiver-drier usually has a sight glass in the top. This sight glass is often used to charge the system. Under normal operating conditions, vapor bubbles should not be visible in the sight glass. The use of the sight glass to charge the system is not recommended in R-134a systems as cloudiness and oil that has separated from the refrigerant can be mistaken for bubbles. This type of mistake can lead to a dangerous overcharged condition. There are variations of receiver-driers and several different desiccant materials are in use. Some of the moisture removing desiccants found within are not compatible with R-134a. The desiccant type is usually identified on a sticker that is affixed to the receiver-drier. Newer receiver-driers use desiccant type XH-7 and are compatible with both R-12 and R-134a refrigerants.

ACCUMULATOR

Accumulators are used on systems that accommodate an orifice tube to meter refrigerants into the evaporator. It is connected directly to the evaporator outlet and stores excess liquid refrigerant. Introduction of liquid refrigerant into a compressor can do serious damage. Compressors are designed to compress gas not liquid. The chief role of the accumulator is to isolate the compressor from any damaging liquid refrigerant. Accumulators, like receiver-driers, also remove debris and moisture from a system. It is a good idea to replace the accumulator each time the system is opened up for major repair and anytime moisture and/or debris is of concern. Moisture is enemy number one for your A/C system. Moisture in a system mixes with refrigerant and forms a corrosive acid. When in doubt, it may be to your advantage to change the Accumulator or receiver in your system. While this may be a temporary discomfort for your wallet, it is of long term benefit to your air conditioning system.