My Tire Pressure warning light was constantly coming on. I had to inflate the

rear tires to over 44 lbs. to get the silly light to stay off. While doing my

pre-race inspection, Marc Thomas commented that my rear tires were wearing too

fast in the middle, a sign of over inflation. I told him about the Tire Pressure

warning and he suggested I bypass the RDK computer. The RDK warning system was

installed on the 928 from 1990 to 1993.

I had read that the RDK computer remembers it prior setting, so I inflated the

tires to 44 lbs. and checked to make sure the Tire Pressure warning light was

off. I then disconnected the battery.

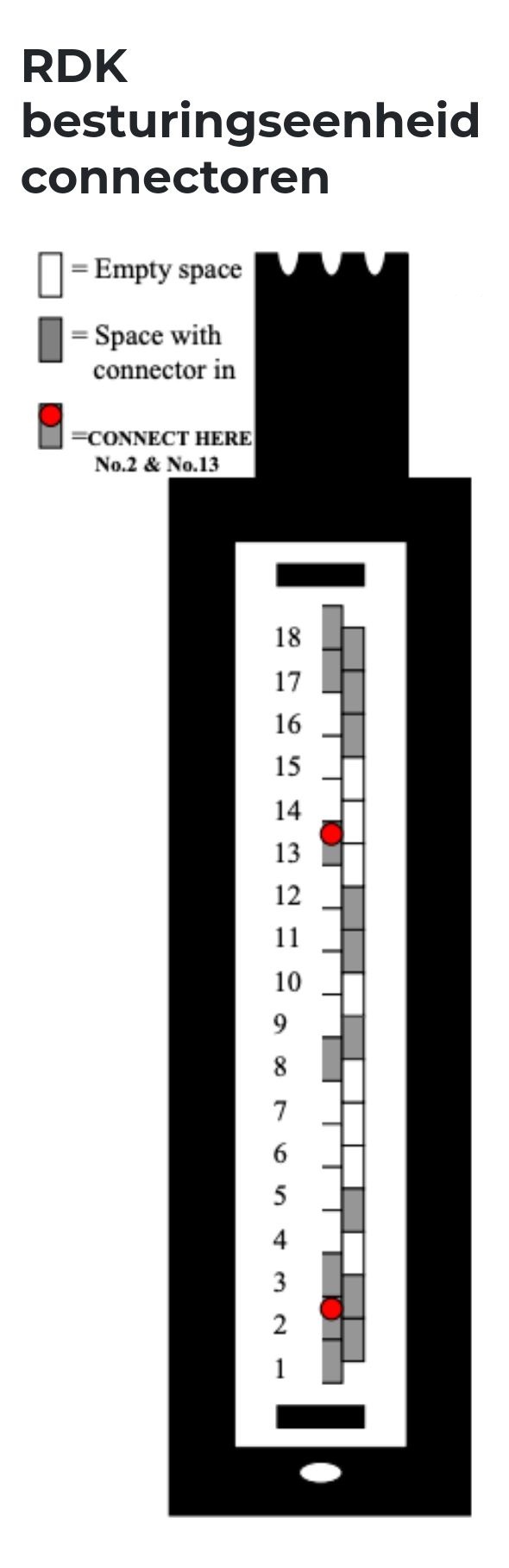

I stuck my head under the dash and found the plug. I had to release the clip on

the wire side and pivot the plug out. I then installed the bypass wire in plugs

2 and 13. I then taped up the exposed end, and used nylon ties to secure it in

place.

I then reconnected the battery and checked the Tire Pressure warning light. I

was still off. I then deflated the rear tires to 38 lbs. and rechecked the

warning light. It was still off.

The whole process took about 15 minutes.

originated from: http://sis125.berkeley.edu/928/wk-rdk.html

========

The ground wire to MPIV (above left knee) is the smallest one of all of them

(0,5mm). This wire is only used by the electronics.

Connected to ground: RDK equipped, No ground connect: no RDK existing.

=========

Bridge Pin 2 and 13 on the connector at the RDK cable, not the RDK itself !

Pin's are numbered, there are two rows, but only one has contacts at positions

PIN 2 and 13. Connector should just be bridged and left disconnected from the

RDK. You may want to cover the contacts with some tape to avoid any short

circuits, and attach it underneath the dash somewhere. The bridge simulates the

RDK so that the Instrument cluster sees on PIN 13 (Ground) that the RDK is

present and ok. Reset the error code in the cluster and the problems are gone.

=========

==========

When troubleshooting RDK problems it makes sensor to know if the error

message (arrow in the digital dash) appears when the car is moving or at

standstill.

Here's some background:

The RDK-ecu compares signals from the pressure sensors which are fitted in the

rim of the wheels. In every rim you have 2 sensors, 180 degrees opposite of each

other. They can be seen easily from inside the rim. The ecu compares the signals

from the pressure sensors and the ABS speed sensors, basically conforms wheels

turning and pressure signals passing by as planned. At the correct tire pressure

the sensor triggers a signal in the pickup device when the rim part passes the

fixed mounted pickup, and sends it to the RDK for evaluation. The ecu checks the

number of pressure sensor pulses with the number of ABS sensor pulses.

If the RDK ecu sees only one sensor signal pass when the wheel has turned a full

revolution, it signals an alarm with at steady-on arrow in the dash display. If

no signal is received at all, the arrow starts to blink, signaling a complete

absence of the pressure sensors signal for that wheel.

Based on the fact that the RDK ecu uses the ABS sensor signal when wheel turns

to determine a revolution and thus checks the two pressure sensors, this system

will only work at speeds starting at about 20 km/h! So from the start of the

engine to about 20 km/h it should not signal any alarms. If so, a faulty RDK ecu

could be causing these problems.

courtesy Holger (partly)