Some of you might remember that I have been studying the Thrust Bearing

Failure (TBF) problem in 928 automatic cars. One area of great concern found by

many 928 automatic owners was the driveshaft pullout at the front flexplate

clamp. This presented itself by a bowing in of the front flexplates toward the

engine and when the pinch bolt was released, the flexplate clamp would move back

onto the driveshaft a few millimeters. This forward pressure is transmitted to

the back of the engine's thrust bearing by pushing the crankshaft into the

bearing.

To remedy this problem, different approaches have been used to stop this

movement. Some have advocated using a new pinch bolt at the front flexplate

clamp and torquing it to a 10% higher foot pound rating, from 59 to

approximately 65 ft lbs. Others have used a loctite formula squeezed into the

splined area of the flexplate clamp. Others have merely decided to check the

movement periodically and relieve the pressure. We decided on a mechanical

solution and want to present it for a possible group purchase by those

interested.

Although we have a lot more information on the whole TBF situation involving the

928, we will focus this post to the information concerning the driveshaft

pullout at the front flexplate clamp. Tests performed to measure the clamping

force of the OE clamps showed deficiencies with them. It is our opinion this

deficiency was exacerbated when it was decided sometime in 1984 to discontinue

the use of a circlip, bearing and washer arrangement at the front of the

driveshaft. These helped set the distance between the flexplate and flywheel. It

also helped the driveshaft from being pulled through the clamp. It is our

opinion the design of the front flexplate clamp should have been changed at that

time. The following is the testing process we used to test the OE clamp and new

clamp.

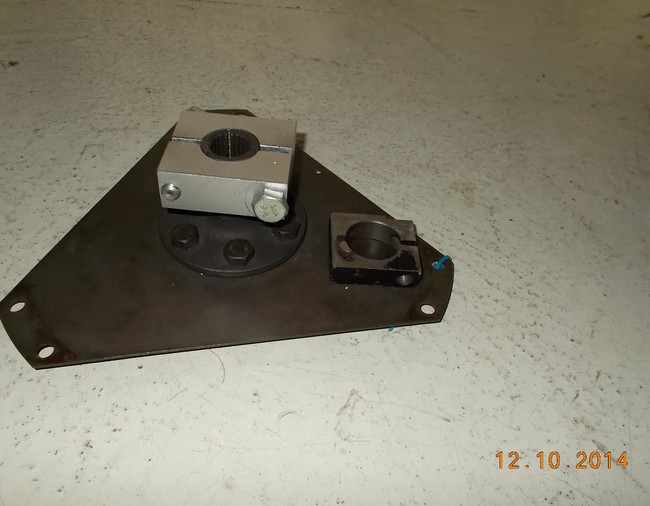

We first tested the OE front flexplate clamp in a test jig made of a press with

a PSI gauge mounted to the press jack. Two OE flexplate clamps were tested with

a portion of a OE driveshaft clamped within. We used both old and new pinch

bolts using the recommended torque ratings of 59 ft lbs and the new, higher 65

ft lb rating and found no difference in the indicated PSI of when the driveshaft

moved. One OE clamp let movement at a registered 1700 psi while the other let

movement at 2100 psi. We then re-clamped the driveshaft into the OE clamp with

the higher clamping force with a new pinch bolt set to 65 ft lbs and heated the

whole affair in an oven for 30 minutes at 200 degrees F, to replicate the heat

soak which occurs when the 928 is running. The front flexplate clamp is right

above the exhaust pipes as they leave the headers. The coupler was tested and

movement occurred at a registered 1400 psi, a loss of about 700 psi.

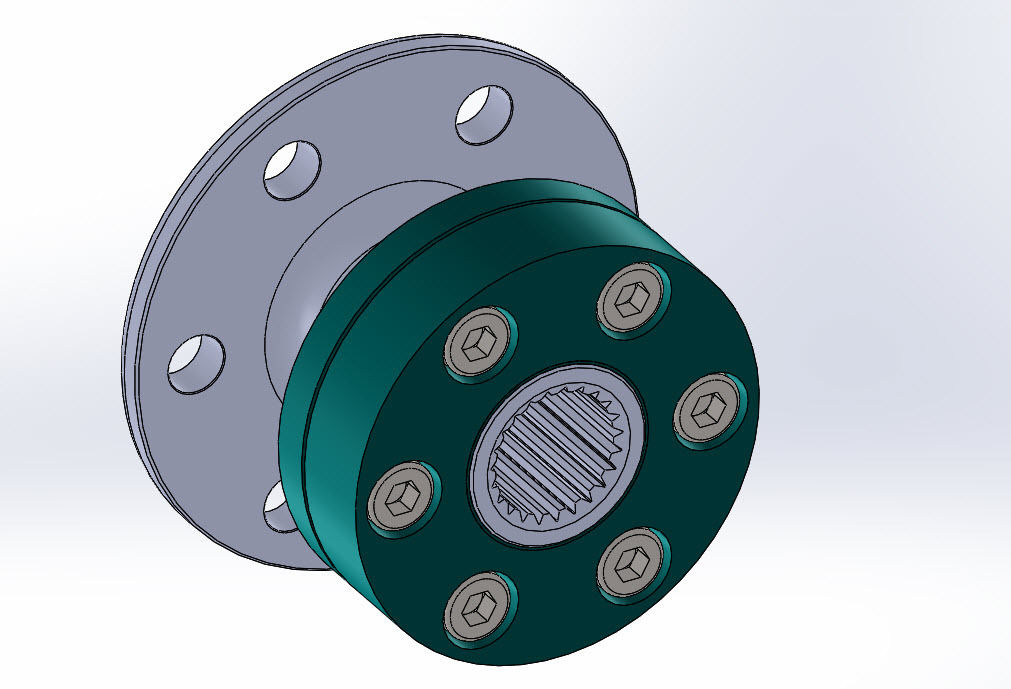

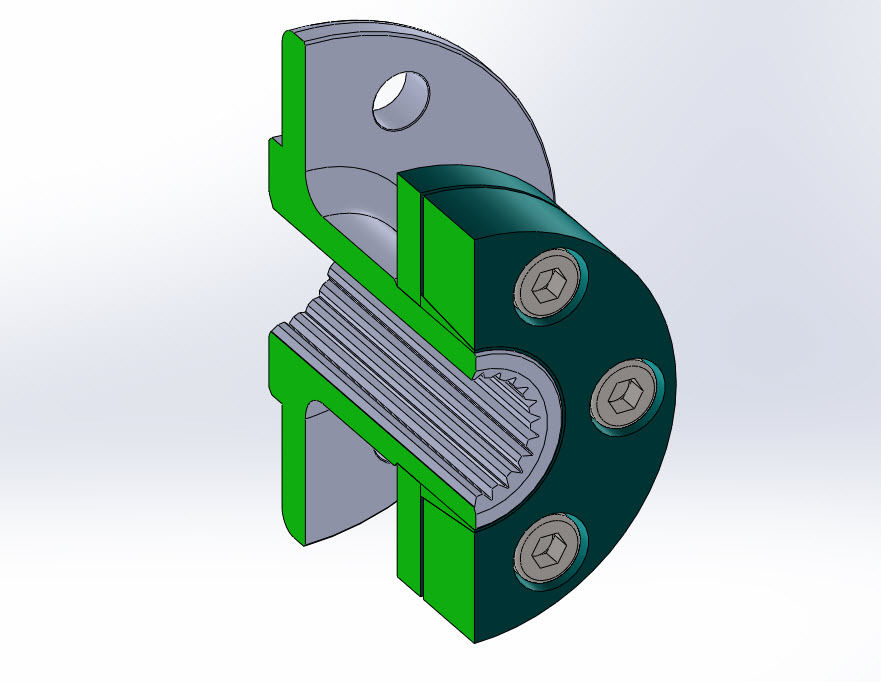

We next tested our new clamp design in the same manner. The six pinch bolts in

the new clamp were torqued to 25 ft lbs each, although they can be torqued to a

higher value. The clamp was tested and no movement was seen up to a registered

4100 psi. The clamp and driveshaft were then heated in an oven set at 200

degrees F for an hour due to it's larger mass and re-tested. No movement was

seen at 4100 psi and the test was stopped at a registered 4300 psi, still

without driveshaft movement. After cooling the new clamp was loosened and the

driveshaft came out easily.

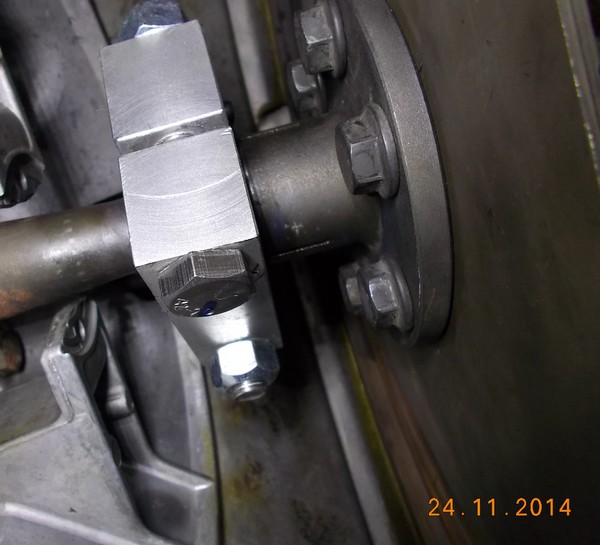

This same clamp was installed in our 1986.5 track car, the one shown in the

"Excellence" magazine, February 2005 edition. The car has been used for PCA

driver education days at local race tracks, and normal road travel for over 5000

miles. Periodic checks of the clamp has not found any movement of the

driveshaft. No forward pressure has been found being exhibited onto the front

flexplate. The clamp was subjected to redline upshifts and full throttle,

kickdown launches from slow corners.

This new clamp can be retrofitted to 928s having both the older constant

diameter drive shaft as well as the newer, thicker driveshaft. The new clamp is

designed to fit onto the OE flexplates after removing the old clamp. The new

clamp can be easily re-adjusted and will last the life of the car since it will

not stretch out as the OE clamp seems to do. The downside to this new clamp is

it can only be installed after removing the torque tube/transmission from the

car.

The other remedies have their own limitations. The new pinch bolt/higher torque

setting does not seem to work. Using loctite solution in the splines has been

found to be hard to readjust, needing heat and force to disengage the coupler

and driveshaft. There was even a reported instance when the coupler had to be

unbolted from the flexplates to remove the torque tube assembly from the car.

Periodic checks and loosening of the front flexplate coupler is not acceptable

since we have found forward pressure to begin within a few weeks of normal

driving, less than 300 miles. Of course, this may vary with driving styles and

other factors and we suggest owners do their own inspections at weekly intervals

to see when movement occurs in their 928s.

Truthfully, we have wavered in offering this clamp to 928 owners. We are not in

this line of business and, in private conversations with a few individuals, some

thought the price too high for most owners, as well as the hurdle of having to

do a torque tube R&R to install it. However, we have also been contacted by some

who have heard about the new clamp and expressed interest in purchasing it. It

is with them in mind that we have decided to offer this new clamp publicly and

find how much interest there is in getting a group purchase together. We suspect

there are 928 owners who want to have a mechanical solution to the driveshaft

pullout problem, one that is worthy of being placed into a 928. We also hope

that other 928 forums are advised of this group purchase by 928 forum members

since we do not subscribe to all existing 928 forums.

The price per coupler will be approximately $350-$375 USD, not including

shipping. The U.S. based manufacturer suggested a minimum order of 25 to make

the price per unit reasonable. The final price will be determined after contact

with the manufacturer to make sure of the manufacturing cost per unit. We

request that anyone interested send us an e-mail directly so we can get a count

of the number interested. If we get the target of at least 25 people, we will

re-contact each buyer and accept payment by Paypal or money order for the clamp

and shipping costs.

If anyone has questions about this or our study into TBF, please feel free to

ask questions. We would also like to publicly thank Mark Anderson of 928

International for donating parts for testing and giving helpful insights to us

during our research.

Constantine

1986.5 928S, AT, Track car

1989 928S4, AT, Daily driver

928 OC member

Rennlist member

By Porken:

And another idea: