Hi,

no... i'm not starting off the TBF discussion again here.

But I am interested in first signs of the problems with the thrust bearing.

What are the first signs and symptoms?

- measurable wear at the crank?

- sound or noise?

- vibrations?

- performance?

- temperature of the engine?

- oil burn (smell)?

- oil/filter contains particles?

- ....

Can the bearing be repaired/replaced?

- when the engine is still running? (not turning)

- when the engine has seized?

- .....

Any real life experiences?

Thanks,

--

Theo

1988 928s4 cherry red

The Netherlands

http://928s4.no-ip.info

=======

On the Rennlist web message board there was a recent case reported where

the symptoms were stalling and slow engine turnover when trying to restart when

the engine was warm. High flex plate load and crank end float were

measured.

On engine disassembly, the thrust bearing face was still largely intact and

the crank weights had not made contact with the block, but the thrust

bearing had spun and ate at the crank journal and bearing saddle and cracked

the block. The thrust bearing has no tabs to prevent it from spinning and

relies on a tight fit to the block, but, as Jon mentioned, excessive load

against the bearing can break through the lubricant film and spin the bearing.

Bill

79

89 S4

=======

Theo,

The only real first sign you could see is particles in the oil filter, probably

accompanied with out of spec endplay on the crank.

All the other things you list are the near terminal signs that occur when the

white metal on the Thrust bearing has all gone, the thrust surfaces are now

steel/steel, the tolerance between the thrust surfaces is too high to maintain

the oil pressure generated by the shear of the oil between the faces (I forget

the technical term for this but the pressure generated is a lot higher than the

5 Bar from the pump) , the thrust bearing is spinning in the block and slowly

machining its way forward thro' the block. Probably accompanied with a bit of

vibration which may or may not be noticeable.

The terminal signs are failure to idle or start when hot along with vibration

..... This is when the crank has moved far enough forwards for the balance

weights to start hitting the block, and sometimes all the endplay in the little

end bearings (gudgeon pin in piston) has been used up so that the rods are

trying to push the piston/s sideways.

In short - releasing the clamp on the drive shaft and checking endplay is

probably the only way of reliably ascertaining whether TBF is happening in the

early stages.

I hope for you that this was a theoretical question?

Jon in NZ

=========

Jon,

thanks for the quick reply! So:

What are the first signs and symptoms?

- measurable wear at the crank (over 0.4mm play)

- oil/filter contains particles

Progressed symptoms:

- sound or noise? How to determine?

- vibrations? Probably?

- performance?

- temperature of the engine?

- oil burn (smell)?

- oil/filter contains particles

- ....

Terminal stage:

- failing to idle

- failing to run when warm

- grinding sound from within the engine

- oil/filter contains particles

Can the bearing be repaired/replaced?

- when the engine is still running? (not turning)

- when the engine has seized?

- .....

Any other comments or experiences?

Hope it remains a theoretical question ;-)

--

Theo

1988 928s4 cherry red

The Netherlands

http://928s4.no-ip.info

=====

Theo

looking at the specs - max end float when new is 0.3mm, max worn is 0.4mm so if

the end float is greater than 0.4mm I would say that you have to pull the engine

(Realistically you can't do the job with the engine in the car) and replace the

thrust bearing.

Realistically if there are white metal particles in the filter you have to pull

the engine, as there is some form of bottom end bearing wear.

If you catch the worn thrust bearing before it spins in the block it is a

relatively simple operation of replacing bearings. If it spins in the block and

you are lucky it only wears away the rear thrust face in the block which can be

repaired by welding and refinished by hand or by fixing semicircular steel shims

with countersunk machine screws into tapped holes in the block.

If the bearing spins and damages the radial faces as well as the thrust faces

the block is probably toast unless you can find someone prepared to build up the

radial faces by welding and then line bore just the thrust bearing back to match

all the others.

From your description in your email to me (which is kind of personal - I could

describe the same noises and stuff in a completely different way which would

mean something completely different to someone else) I think your next step is

to get underneath, undo the front clamp on the drive shaft and measure the

end float on the crank. This is the only way to put your mind at rest (or confirm

the worst). Sorry.

But if you catch it early it is just a set of bearings and a new Oil pan gasket.

Jon in NZ

======

Thrust bearing failure

Date Posted

11/14/2001

Posted By

"Jim Bailey"

Message:

failure of the main bearing thrust bearing is very rare in a 5 speed , the

drive shaft slides freely through the center of the clutch discs . Which

means it cannot push the crankshaft forward or pull back overloading the

side flanges of the bearing . The only time it is under load is when the

clutch pedal is depressed and the clutch arm is pulling the release / throw out

bearing back away from the engine . This pulls the pressure plate

fingers away from the friction discs allowing the flywheel and pressure plate to

continue rotating but the disc (or discs) and drive shaft and 5th

gear stop rotating . Which is just another reason not to wait at a stop light

with the car in gear holding the clutch to the floor .. The release

bearing does not like it , the pressure plate does not like it , the motor

thrust bearing does not like it and if the rubber clutch hose should burst

.. You just " popped the clutch" and away you can go.. But back to the thrust

bearing .(very simplified) The surface of the main bearing where the

crankshaft passes through is like a metal arm band around your wrist only your

wrist is spinning at 6,000 RPM . Without oil the softer bearing

surface metals quickly overheat and erode , continued and it scratches and

begins overheating the crankshaft do it long enough and the crankshaft may

crack . The damages increases the clearance between the bearing and the crank

and internal knocking noises may be heard (failed rod bearing really

knock but a higher lighter knock ). Normally oil pressure creates a film of oil

between the crankshaft and the bearing and the metal never touches . As

it turns a small wave of oil is pushed along the bearing surface . The sides

flanges of the thrust bearing (the part which keeps the crank from sliding

back and forth) do not push a oil wave around but the spinning crank acts like a

potters wheel and wants to sling the oil away from the surface which

is one reason it cannot withstand much pressure front to back but can handle the

pounding of all the explosions for thousands of miles. The typical

indication of failed thrust bearings will be that the engine will not turn over

when hot ,the starter motor is not strong enough to overcome the drag

or when changing oil the oil looks like silver metallic paint from all the

ground up metal . It can be checked by measuring how much endplay you

observe , measure when prying the crank shaft back and forth .

Jim Bailey

928 International

Jim@928intl.com

www.928intl.com

(714)632-9288

=========

From: <Rickythorpe at aol.com>

To: <928uk at 928.org.uk>

Sent: Thursday, October 09, 2003 3:22 PM

Subject: [928uk] re seizing engine

when my 1985 S2 does approx 20 miles and gets hot it stalls you then wait 10 to

15 minutes and it will start again but wont idle it is also very sluggish to

start. a garage has changed the air flow meter, battery and repaired the starter

motor [apparently it was faulty] i still have the same problem and they are now

telling me it is the thrust washers around the crankshaft possibly but they can't

be certain, all this from a main Porsche dealer, ouch! any ideas please.

===========

From: 928uk-bounces at 928.org.uk [mailto:928uk-bounces at 928.org.uk]On

Behalf Of Paul R Smith

Sent: 09 October 2003 16:35

To: Rickythorpe at aol.com; 928uk at 928.org.uk

Subject: Re: [928uk] re seizing engine

I assume your car is an auto?

IF it is the crankshaft thrust bearings, this is very serious. It is almost

always caused by the flex plate becoming pre-loaded.

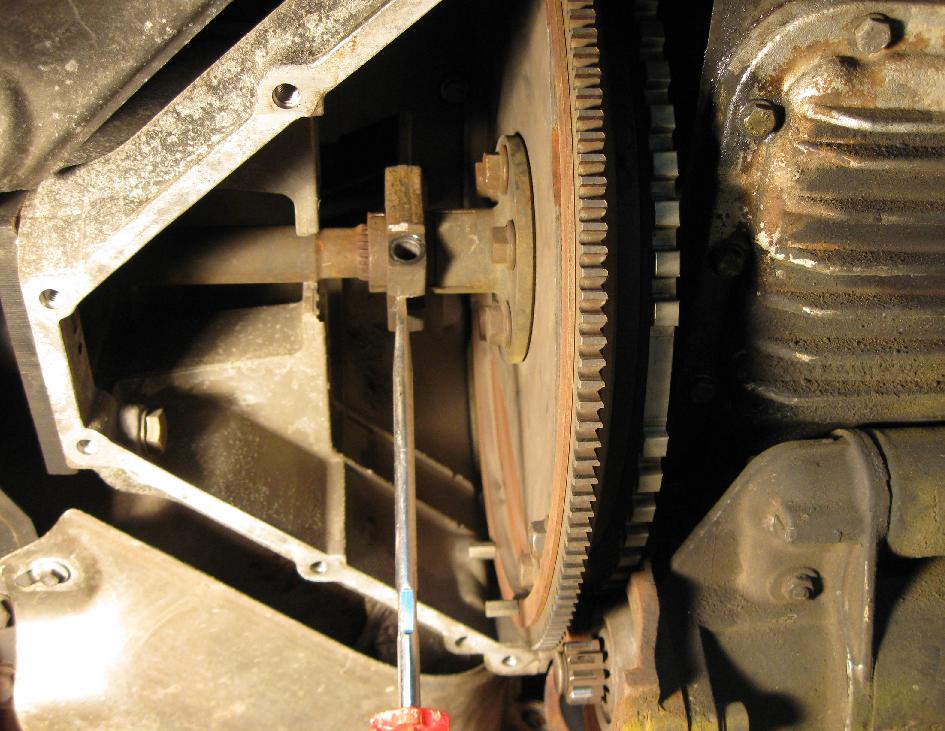

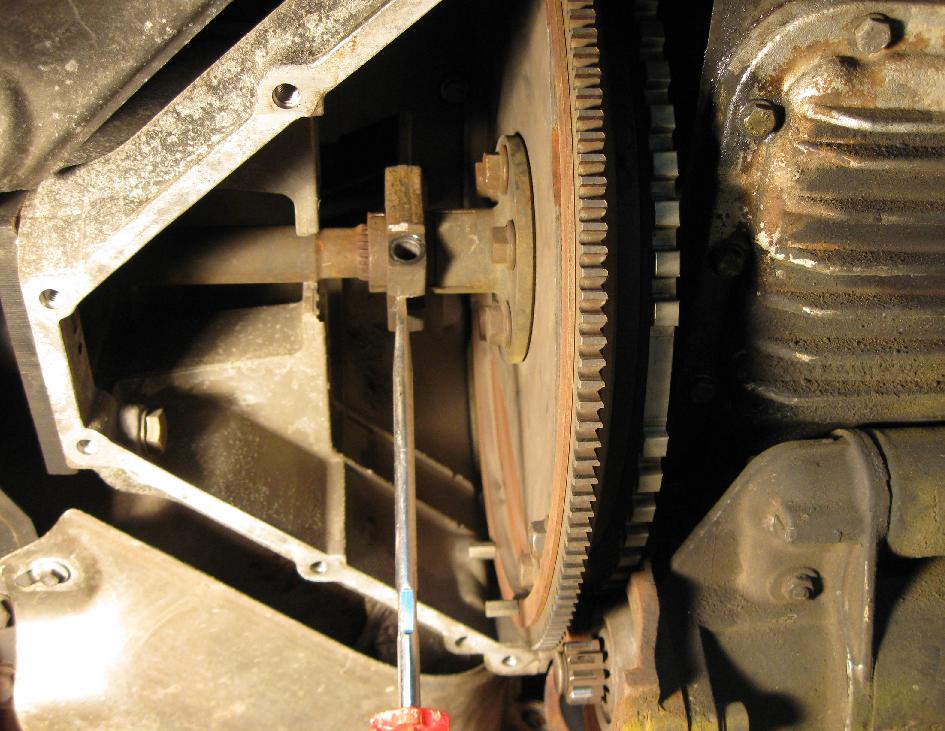

What you must do is stop driving it, take off the lower bellhousing (6 bolts),

then slacken the big allen screw clamping the flex-plate to the drive shaft, and

check how far the clamp moves (this indicates how much the flex-plate was

pre-loaded).

Then you need to move the crankshaft forwards and backwards and measure how far

it moves. This will indicate how worn the thrust bearings are.

If they are worn beyond the wear limit ( 0.4 mm ), its an engine out job to

change. If the wear is much greater (say 2 mm ) there is a serious danger that

the crankshaft is scrap. If you continue to drive it, you will also scrap the

block, and risk it seizing solid.

If you're not up to checking it yourself, get it looked at by someone who can.

Ignoring this will be fatal to your engine.

Smiffy

===========

Ricky

The symptoms you describe are the classic symptoms of impending thrust bearing

failure due to preload of the flex plate. Amplifying what Smiffy has

said; If the Engine is not making knocking noises then there is a chance that

the centre main thrust bearing has not spun in it's housing (Yet !). If

this has not happened then you may find that there is no critical crank damage.

Yes the counterweights on the crank may have been wearing against

the block but this in itself is not critical.

As smiffy says you need to check how much end float there is. and relieve the

preload that has built up. You may also find that the engine does start

knocking after you have relieved the preload. From your description it does

sound bad enough that you will have to pull the engine and change the thrust

bearing as a minimum. I hope that the bearing has not spun. Once you go down the

route of pulling the engine there is a whole list of other stuff you may

as well do wyait.

I have a series of pics of what happens when the bearing spins I could send you

if you like but they are about 10Mb worth.

Regards

Jon

======

Theo

looking at the specs - max end float when new is 0.3mm, max worn is 0.4mm so if

the end float is greater than 0.4mm I would say that you have to pull the engine

(Realistically you can't do the job with the engine in the car) and replace the

thrust bearing.

Realistically if there are white metal particles in the filter you have to pull

the engine, as there is some form of bottom end bearing wear.

If you catch the worn thrust bearing before it spins in the block it is a

relatively simple operation of replacing bearings. If it spins in the block and

you are lucky it only wears away the rear thrust face in the block which can be

repaired by welding and refinished by hand or by fixing semicircular steel shims

with countersunk machine screws into tapped holes in the block.

If the bearing spins and damages the radial faces as well as the thrust faces

the block is probably toast unless you can find someone prepared to build up the

radial faces by welding and then line bore just the thrust bearing back to match

all the others.

From your description in your email to me (which is kind of personal - I could

describe the same noises and stuff in a completely different way which would

mean something completely different to someone else) I think your next step is

to get underneath, undo the front clamp on the drive shaft and measure the

endfloat on the crank. This is the only way to put your mind at rest (or confirm

the worst). Sorry.

But if you catch it early it is just a set of bearings and a new OIl pan gasket.

Jon in NZ

======

Ok, for all of you wondering what my query was all about, here's the what and

why:

My car suddenly started to sound different after a long drive, hollow,

resonating, and vibrated a lot at 2000-3000 rpm. Its never been like this

before. I feared a TBF as some of the symptoms seemed to match and all other

things I checked seemed ok. Idle was ok, and the symptoms did not change warm or

cold.

I went to see an independent Porsche mechanic who is very 928 experienced, and

asked for his advice. He almost immediately said that part of the sound was from

the motor mounts being collapsed. I knew the engine was low in the bay but did

not expect it to cause this. He also said to replace oil and filter, and

carefully inspect oil and filter for particles. If none exist, just put in a

good oil and it will be ok.

I did. Found no particles or signs of wear in the filter. None. But a few

particles in the oil that looked like sand. Strange. Could not find any in the

filter. Definitely not looking like metal. (Puzzled, I am)

After filling up with oil I ran the engine for a few mins and it seemed more

quiet. I did a test-drive and the difference is substantial. The vibrations are

still there more or less (mounts) but the engine sounds like it used to do. I

tested at some speed and accelerated a few times. All seems back to normal.

Let's hope it was all false alarm.

The lifters are also a lot less noisy. I immediately noticed this change.

So........ my lessons:

1. don't get worried and suspect engine failure right away

2. I do need to put in those new mounts I have

3. Oil does degrade and needs to be of good quality

Oh, and for those of you believing people saying you only need to add oil: I

don't believe this. I replace oil and filter at least once a year or at 20.000

km and use a new filter. I'm actually driving just 10.000 km a year or so. Oil

"wears out" and gets contaminated!

regards,

--

Theo

1988 928s4 cherry red

The Netherlands

http://928s4.no-ip.info