The Thrust Bearing Failure, also called TBF.

This article is all about the Thrust Bearing Failure. Its an extract of information provided on the internet and newsgroups and tends to deal with those issues and idea's that are said to be related or causing the problems.

First of all: what is this all about?

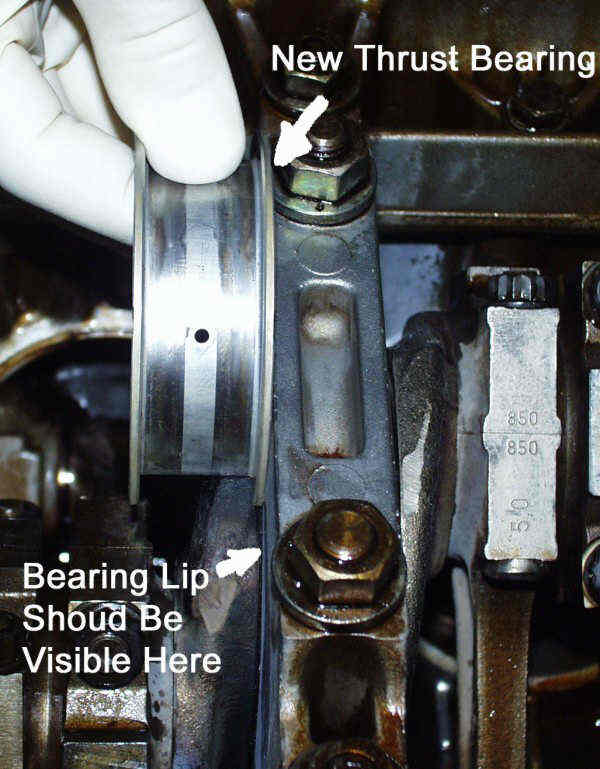

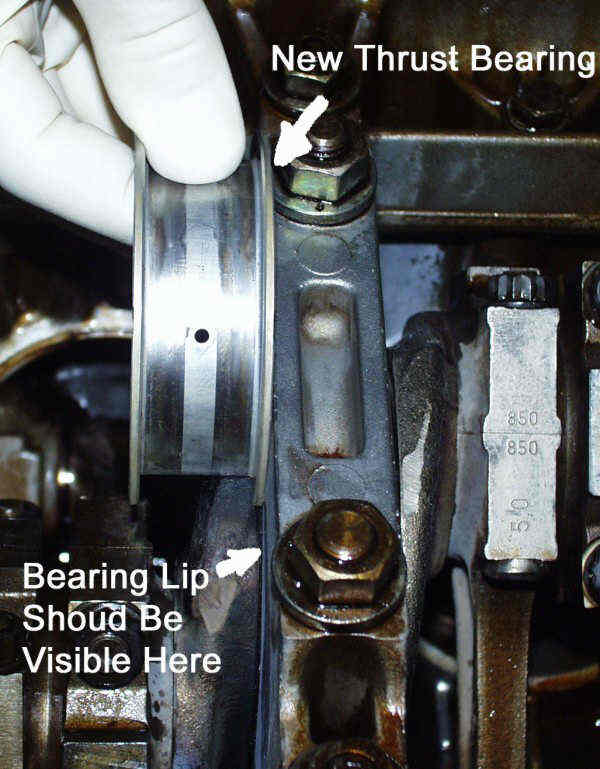

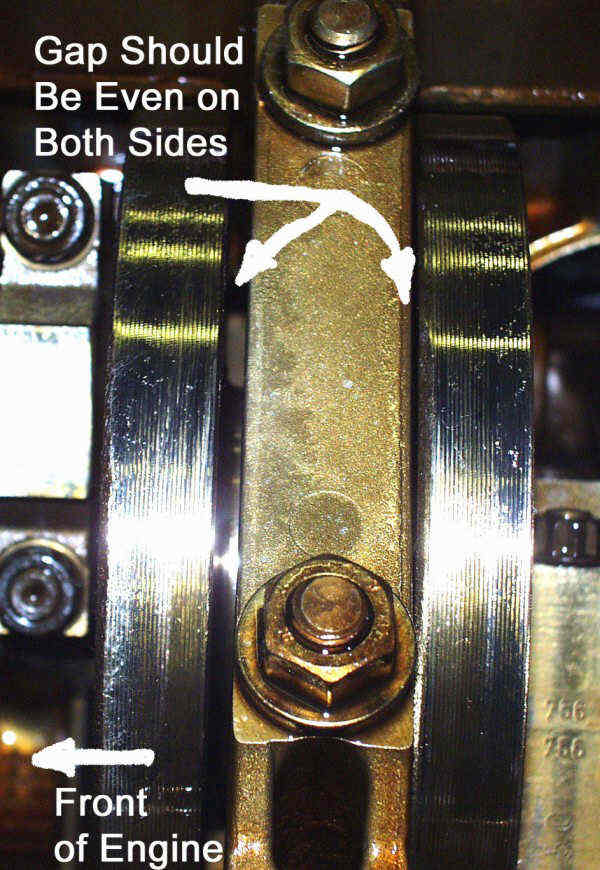

Well, the 928 engine has a crank-shaft. Pistons drive the crankshaft. In principal the pressure on the crankshaft in radial, acting in a 90 degrees angle on the crankshaft. Therefore the crankshaft has decent bearings to cope with the forces. In the center of the crankshaft the 928 engine has a thrust bearing. That bearing is a small one, dealing with the axial forces that exist when the engine runs. Basically it prevents the crankshaft from drifting away from the seating of the bearings. It keeps the crankshaft in place.

Fine, so what is the problem?

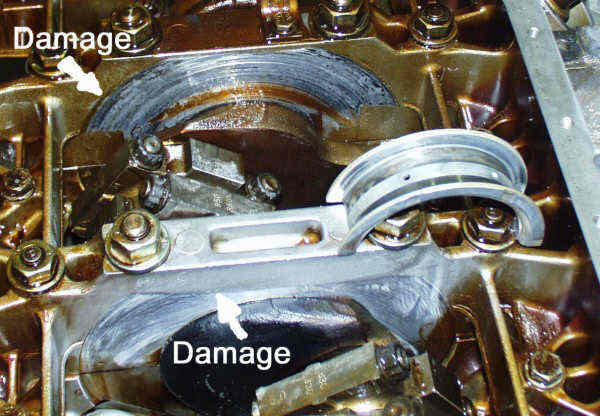

ok, for quite some time now there have been reports about Thrust Bearing failure causing a massive disaster in the engine, and leaving engines beyond repair. Porsche has had service claims for new engines that made them release a field bulletin to address the issue.

The problem of the moving crankshaft only happens on 928 with automatic transmission. It has not been reported on the cars with manual transmission. So apparently some severe force starts acting upon the crankshaft pushing the engine towards the front of the car. That is not good. Porsche states that the problem is related to wrongly mounting the transmission, leaving a force on the flexplate, causing a permanent pre-load on the flexplate and thus pushing the crankshaft to the front. Porsche states that after mounting the tranny, the *last* step should be releasing the pressure on the flexplate by loosening and tightening the pinch bolt in the clamp on the front-side of the Torque Tube. (where the flexplate attaches the Torque Tube)

So there IS no problem?

Its not all. 928 owners have reported a pressure buildup on many occasions, where there was absolutely nothing pointing to tranny mounting problems. There must be another cause. This has been basis for many discussions on 928 Rennlist and 928 Forums. Here are the most common ideas:

Now, both the TT shrinking as the TC swelling may be actually true. I fancy the TT shrinking option for now. Its still unsure which is causing the problem. Options 2 and 3 seem to compensate each other under severe load as the TT shrinks when the TC swells (LOL). There is serious doubt if only wrongly mounted trannies are responsible for the phenomena as Porsche stated.

What can be done?

I personally dislike all options but the first one. I think its not a good idea to lock the splines, since it also acts as a safety device, allowing excessive force to let the TT move along the splines instead of pushing even harder on the Thrust Bearing. Some said I'm wrong, but I'm stubborn AND Dutch ;-))

One piece of sound advice: release the clamp every 30.000 km, make a small lamp that fits inside the hole in the bottom cover of the flexplate to inspect (inspection hole), and after putting the flexplate into rest-position: paint the shaft with red or white paint. That will show any movement easily without removing the exhaust and the cover plate, and make you decide if its necessary to open things up again.

This end my little summary, hope it helps someone. Any comments, new facts or proof appreciated !

Theo