<From 4/13/2002>

Jay,

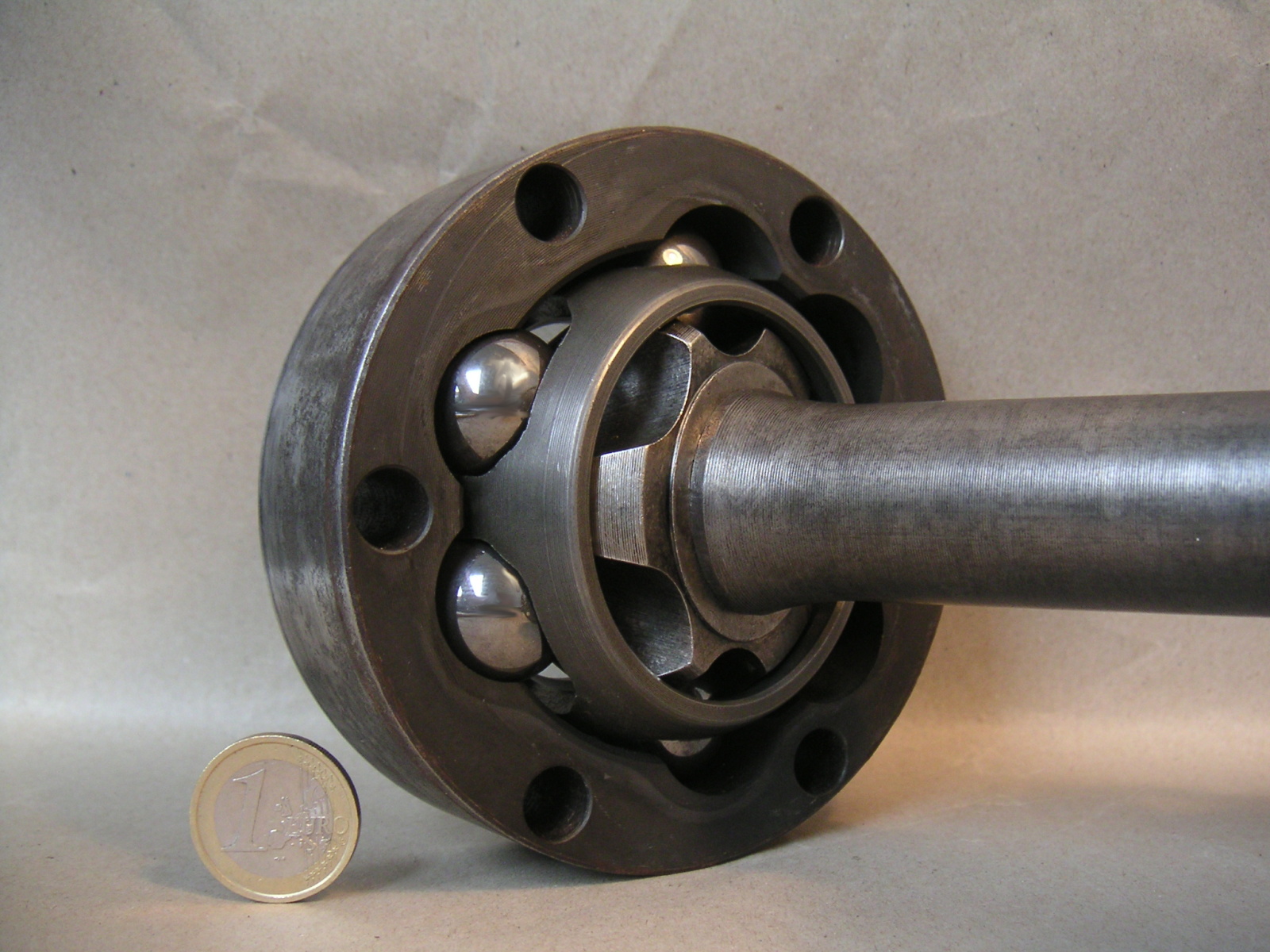

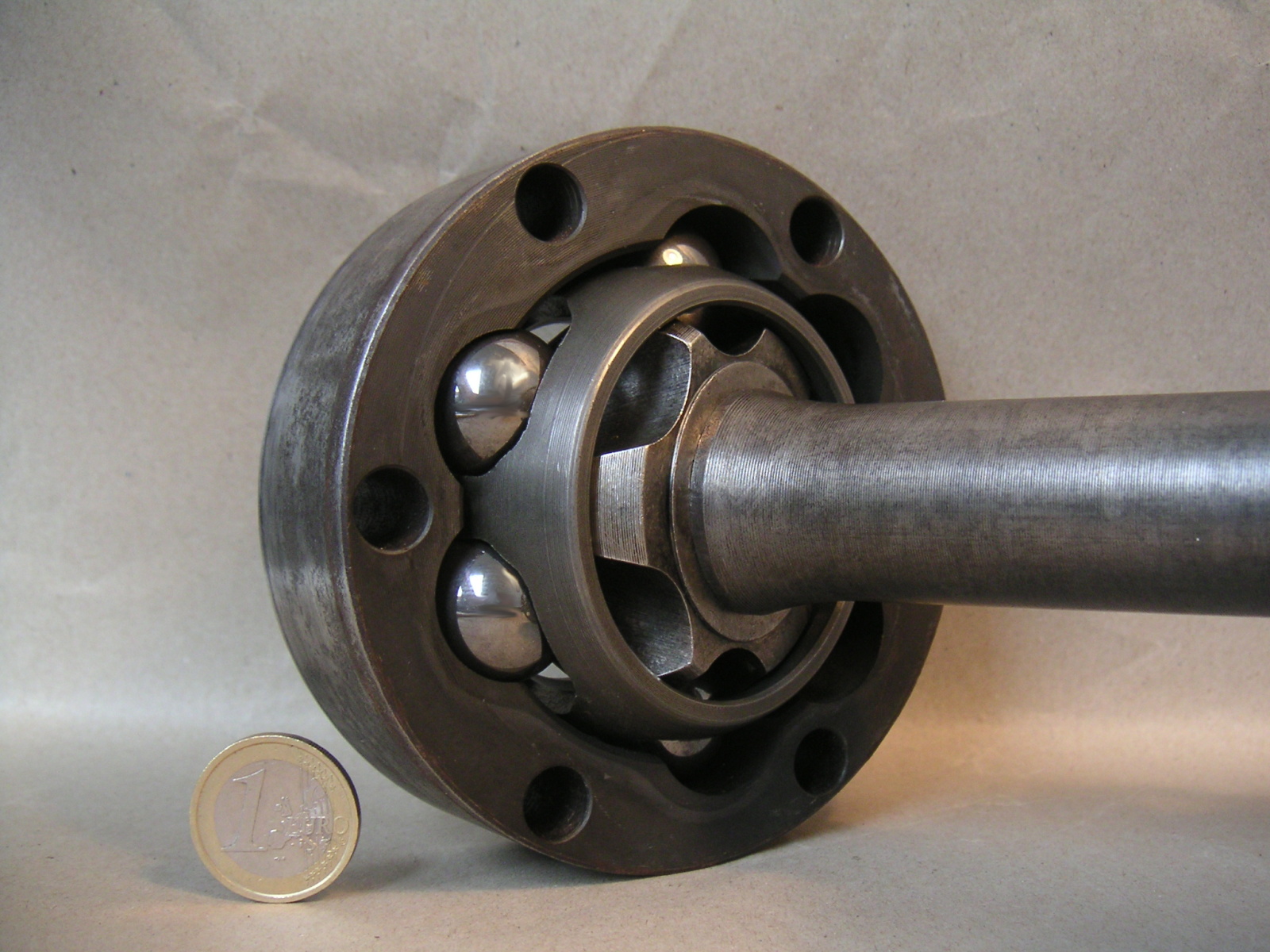

Swapping around the ends does reverse the rotation direction, but it doesn't

change the drive surfaces. (Or are we in agreement on this?) Here's a picture of

the right side:

/\ ''''''''''''''''

'''''''''''''''''' |

/ \ '''''''''''''''' '''''''''''''''''' |

|

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

|

|

'''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''

\ /

| ''''''''''''''''''''''''

''''''''''''''''' \/

' '''''''''''''''''''''''

''''''''''''''''''''

What I'm showing with the arrows is the direction of the force at the upper side

of the joint. The tranny is applying torque to accelerate the car. The wheel

(and road) is applying an opposite torque to the shaft.

If the ends are swapped, the arrows are still pointing the same way with respect

to the joint. (The picture is the same when viewed upside down.) Moving the axle

to the left side would reverse the arrow direction (the

torque) and the "fresh" surface would get the heavy wear.

Wish me luck on my carpet job. It sure looks like a lot more work once the

pieces are spread out.

Glen

=========

Jay Kempf wrote:

I have the originals 78 Manual set with updates for 79.

There is no mention of the cage being installed one way or the other.

There is mention of the groove in the hub and the groove on one end of the shell

being installed on the same side. However, the picture shows several times a

joint that has no groove in the outer and one of mine was like this so I

compared them and there is no difference in the way the joint goes together. I

have put them together both ways and they still look like they function properly

to me. For that one joint I have no idea which way the outer shell is installed

but it works.

There is no mention of glue and there is only mention of the paper gaskets on

the flange side of the joint not the axle side which makes no sense unless it is

to isolate two different types of steel for corrosions sake or something. I left

them all out and have no leakage.

The check statement means that if the hub can move in and out of the outer shell

freely and smoothly until it basically locks up at about half the hub showing

while holding the faces parallel that is correct. This is needed so that when

the suspension moves and the overall length needs to change slightly it can. If

you install the hub backwards it won't.

If you just swap ends on the axle you are reversing its rotation and so you >

are working the balls into an area of the shell and hub where they haven't been

riding. This should help to extend the life of the joint and may eliminate or

reduce clicking if the joint is worn. If there is clicking the factory

recommends that you replace the joint. The newer style joints can only do this

if you swap sides because the joints different inner to outer and won't

interchange. Many have done this swap and saved an axle that really needs

replacement. This applies to more than just the 928 or Porsche for that matter

and is a common practice on any CV car.

There is no change in the torque value for a fastener that has either Loctite,

lube or anti seize. But you need to make sure that you don't get ANY of

these fluids on the face of the head of the bolt or the mating surface! If

you do you may snap the fastener or overstress it causing a catastrophic and

spontaneous disassembly. Axles especially should be torqued properly. There

should be no reason to put Loctite on these bolts as they are high strength,

high torque and used in their linear elastic range way below yield. The

factory would probably tell you to use a new bolt every time you

disassemble this joint but I see no reason for that as long as > there isn't

major pitting on the mating surfaces and with the high strength nature of both

pieces that is unlikely.

If you are having trouble fitting the boots try a regular old hair dryer on >

them before assembly. Tight is good. And don't lube them on the mating surfaces

if you can avoid it. Tough with all that grease. Messy job in general

Good luck.

Jay Kempf

79 US 5ish speed.