Pages from Service Info Tech 1989-1994.pdf

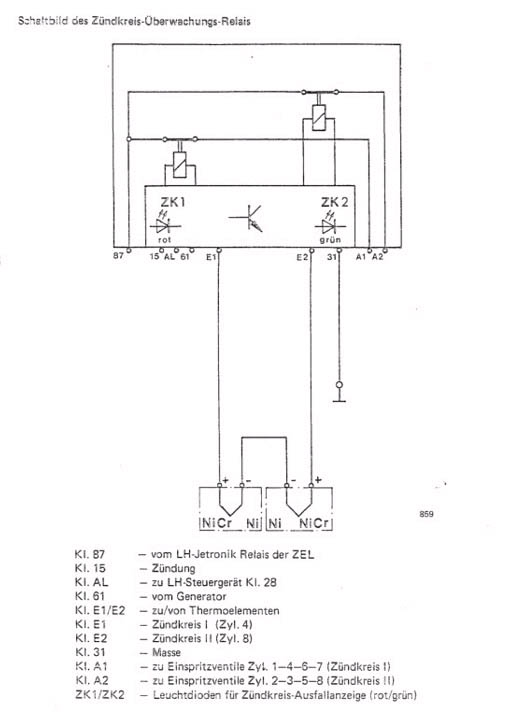

Part II: The Ignition Circuit Monitoring Relay

The 928 S4 and newer engines have two separate ignition circuits. Ignition

circuit 1 is comprised of cylinders 1,4,6,7, the right side coil and

distributor. Ignition circuit 2 is comprised of cylinders 2,3,5,8, the left side

coil and distributor. If there is a failure in one of the ignition circuits, raw

fuel is pumped out of the cylinders and into the exhaust system. When the raw

fuel hits the hot catalytic converters a fire may occur – OUCH!

From model year 1989 onwards, Porsche added the Ignition Circuit Monitoring

Relay as a safety feature. This circuit is completely independent of the LH

injection system. It is identified in the workshop manual wiring diagram as the

Ignition Control Circuit. The function of the system is to turn off the fuel

injection to the failing ignition circuit. The inputs to the relay are two

exhaust temperature sensors that provide input to the relay. If one of the

ignition circuits fails, the “Ignition Circuit Monitoring Relay” shuts off the

pulse signal to all of the fuel injectors of the affected circuit.

As you might imagine, the symptoms of a shut down ignition circuit are a

significant reduction in power and a rough running engine. For trouble shooting,

you need to determine if the shut-down is due to a failed ignition circuit or a

failure of the Ignition Circuit Monitoring Relay itself.

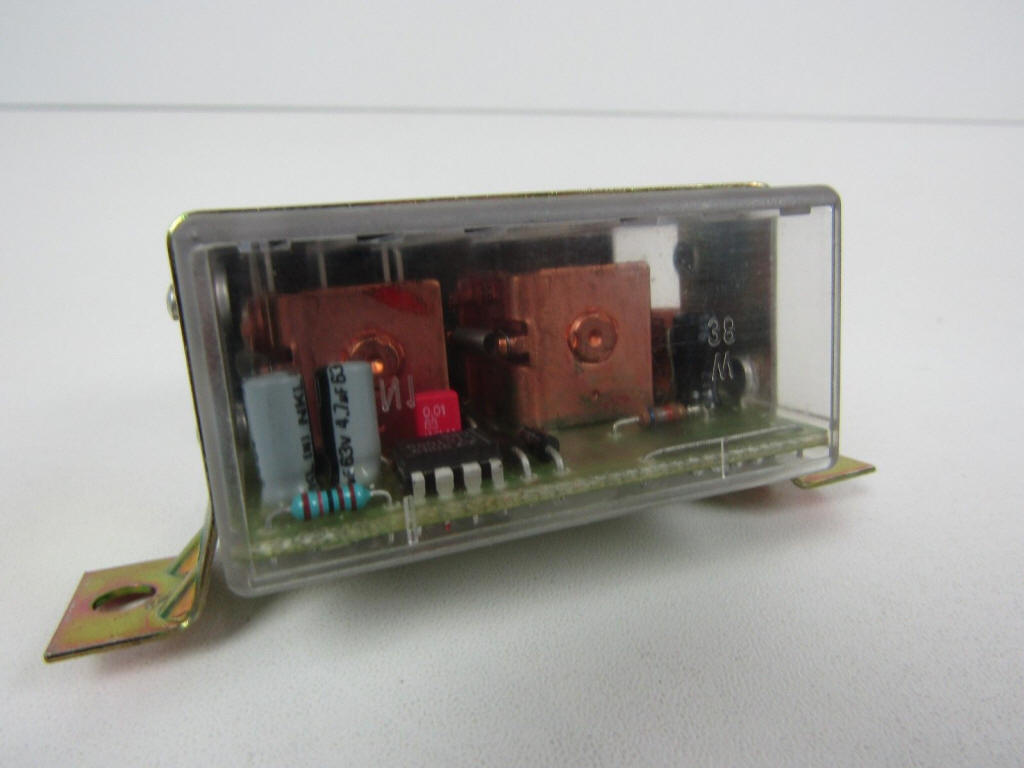

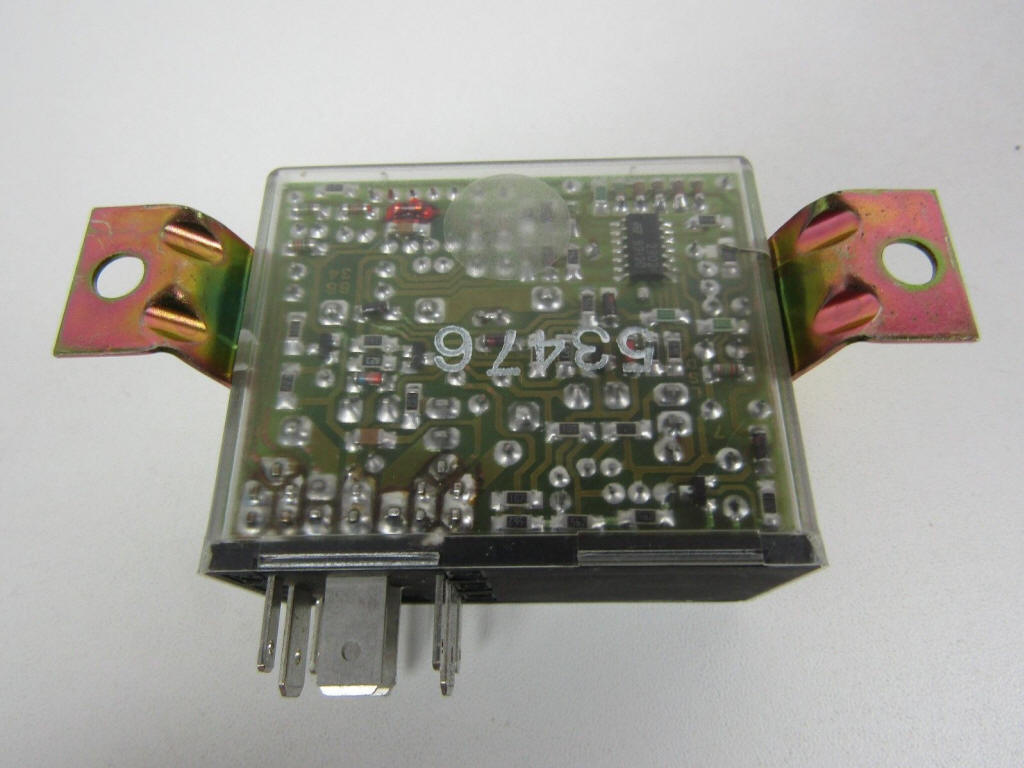

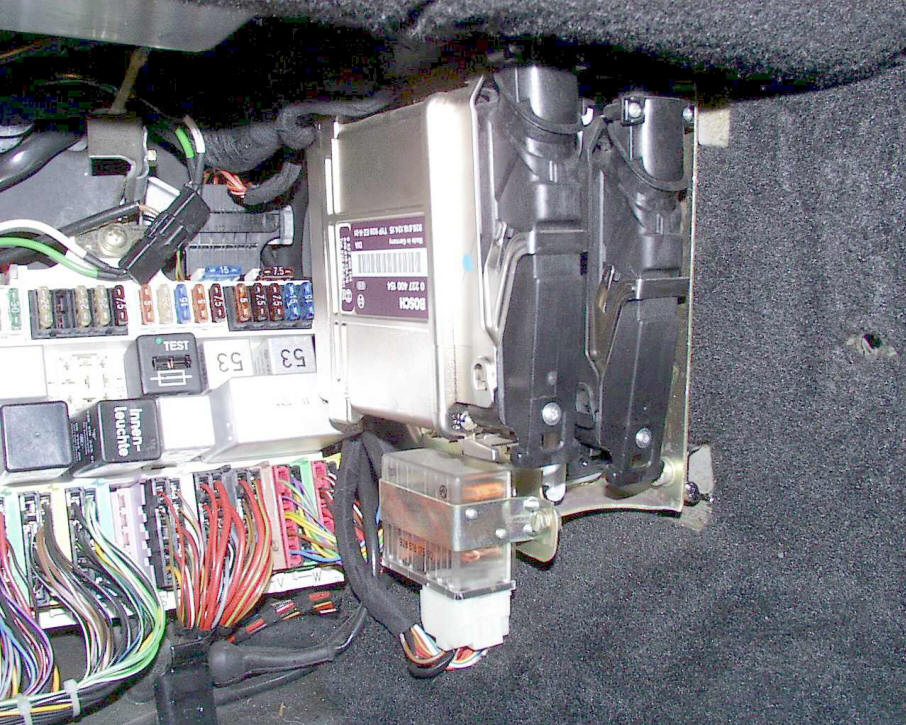

The first step is to quickly identify which circuit is affected. Look at the

clear relay module that is fitted next to the EZK spark control unit in the

passenger compartment.

When ignition circuit 1 (cylinders 1,4,6,7) is shut-down, a red LED is

illuminated.

When ignition circuit 2 (cylinders 2,3,5,8) is shut-down, a green LED is

illuminated.

Check the ignition circuits and repair as necessary. If no problem is found with

the ignition circuit, there may be a failure of the Ignition Circuit Monitoring

Relay circuit, the signals to test are:

1. Terminal 31: ground

2. Ground must be present at terminal AL when the ignition switch is in the off

position.

3. Battery voltage must be present at terminals A1, A2, 15 and 87 when the

ignition is in the on position.

4. Battery voltage must be present at terminal 61 when the engine is

running.

5. AL outputs a voltage signaling the

LH that the IMR is in normal operation (no faults to be logged).

6. A Voltage value of approximately 2.7 V must be present at both terminals E1

and E2 when the ignition is in the on position. *note: I

don't think this is correct. You should see almost 0mV when the engine is warm

and running. The temp sensors should supply about 2.5mV but they are connected

in reverse polarity so that +2.5mV and -2.5mV result in 0mV difference.

7. The resistance between E1 and E1 is approximately 5 – 10 Ohms (measured at

the disconnected relay socket). This is the resistance or two sensors in series.

The temperature sensors that fit in the exhaust system should also be inspected.

A more detailed explanation is provided in the factory workshop manuals.

Rich Andrade (some adjustments by Theo Jenniskens)

Special Features of ignition Circuit Monitoring Relay

Since the four cylinders still draw in air after switching off the injection

circuit, the oxygen sensor would recognize excessive air and regulate the

air/fuel mixture of the perfect condition cylinders in rich direction. Oxygen

sensor control is switched off together with switching off the ignition circuit,

in order to prevent this.

Terminal 15 of the relay has voltage via CEL when turning on the ignition.

Terminal AL of the relay (this wire leads to LH control unit term. 28) has

ground with “ignition on”.

With “ignition on” the LH control unit will be coded for operation without

catalytic converter via term. AL of the relay, since the coding, whether with or

without catalytic converter, for the LH control unit is accomplished via

positive or ground on term. 28 of the LH control unit.

If the engine is started and term. 61 of the relay has alternator voltage,

voltage is supplied to term. AL and the LH control unit is therefore coded for

operation “with catalytic converter”.

If an ignition circuit would now fail and the pertinent relay contact opens.

Ground would be applied on term. AL and the LH control unit switches over to

operation “without catalytic converter”.

Since, however, in cars without catalytic converter idle speed CO level

adjustments are made via a potentiometer and this potentiometer on the other

hand is not installed in cars with catalytic converter (adaptive oxygen sensor

control), a 150 ohm resistor integrated in the coding plug of the LH or EZK

control unit sends a fixed value (replacement value) to the LH control unit for

guarantee of engine idling when the ignition circuit monitoring relay switches

and therefore oxygen sensor control is switched over to control without oxygen

sensor.

Delayed Switching

The relay is inoperative for about 18 seconds after each engine start, in order

to prevent unwanted switching of the ignition circuit monitoring relay due to

non-uniform cooling of a stopped engine There must also be a difference in

voltage of > 6 mV on connections El and E2 for at least 2.5 seconds before

activation of the relay.

Self-monitor

Great differences in voltage on connections El and E2 are recognized as faults

on the thermo elements or their power supplying leads by a circuit integrated in

the ignition circuit monitoring relay. This always causes switching off of fuel

injection circuit for ignition circuit I or II and activation of the green or

red light

emitting diode. Resistance can be measured on connections El and E2 of a

disconnected relay plug with an ohmmeter to check the thermo elements and power

supplying leads.

Approx. 5 to 10 ohms between El and E2 for perfect condition thermo elements and

leads.

Ohmmeter displays open (-ohms) in case of a fault.

---------

Well, I'm confused now.

The ignition monitoring relay (the one with a green and a red LED) monitors

exhaust temperature. I assume it does this to discover if

unburned fuel possibly are getting into the exhausts, which means it could enter

the cats, causing expensive damage.

In such a situation it then shuts off that bank (by cutting fuel).

This is what I have believed. However, Wally Plumley stated that the system does

not work this way. The ignition monitoring relay actually

shuts off four cylinders, but based on which ignition circuit they are in. This

makes sense, since they LEDs of the monitoring relay are

connected to which ignition circuit is bad. But this means that you will not

know where the problem is, if you just monitor exhaust temps, since both

ignition circuits contribute to both exhaust sensors.

So. How do this work? Will the ignition monitoring relay shut down four

cylinders (two in each bank), or shut down one whole bank?

Johnny

------

Johnny,

One sensor picks up from one side indicating the 3 temp and the other on the 7

cylinder. It responds if one is low temp compared to the other one. This results

in activating of the relay and shutting down one set of injectors. The injectors

are wired identical to the ignition, so not 1234 and 5678 but 1467 and 2358. So

shutting down fuel supply to one set is matched to failure of that ignition

circuit.

In the 89 and 90 models, the sensor was at the 4 and 8 cylinder, but this

changed in 1991 to the 3 and 7 cylinder. Yes, the other cylinders also

contribute but apparently not so much that it is not able to tell which is

failing (less heat). It seems that Porsche changed their mind in 1991, maybe

because of unjustified activation. Not sure, just guessing.

IMR -> Green LED = Driver side problems, Red LED = Passenger side problems.

regards

Theo

1992 928gts Midnight Blue (2006-)

1988 928s4 Cherry Red (1999-2006)

The Netherlands

http://jenniskens.livedsl.nl

http://928gts.jenniskens.eu

-------

Theo has explained it well, so this is a bit redundant...

The late 928s have two virtually independent ignition systems. There were

sufficient cases of failure of one of these ignition systems, followed by

overheated cats leading to serious fires, to convince Porsche that Something Had

To Be Done. That Something was the Ignition Monitoring System. The exhaust temp

sensors of that system measure the EGTs of two cylinders - one on each ignition

system. If the EGTs of the two cylinders become different enough, the Ignition

Monitoring System relay kills the fuel injectors feeding the four cylinders

fired by the ignition system including the cylinder with the cold exhaust.

The key is that the Ignition Monitoring System monitors the EGTs (Exhaust Gas

Temperatures) of two individual cylinders, not the EGTs of the left and right

banks. The fuel injectors were divided into two sets of four, matching the

arrangement of the ignition systems. All injectors still batch fire at once, but

they are fired by two different sets of wires contained in the single injection

harness.

Wally Plumley

928 Specialists

www.928gt.com

=========

Here is Porsche's official IMR check procedure:

Ignition monitoring diagnosing.pdf