From: Wally Plumley <wplumley@refugee.services.peach.net>

Date: Wed, 07 Jul 1999 08:33:37 -0400

X-Message-Number: 9

There has been some discussion of valve lifter tapping -

If the problem is lifter tapping immediately after cranking the engine, the oil check valve in the cylinder head may need cleaning. Page 17-10 in the shop manual covers the procedure.

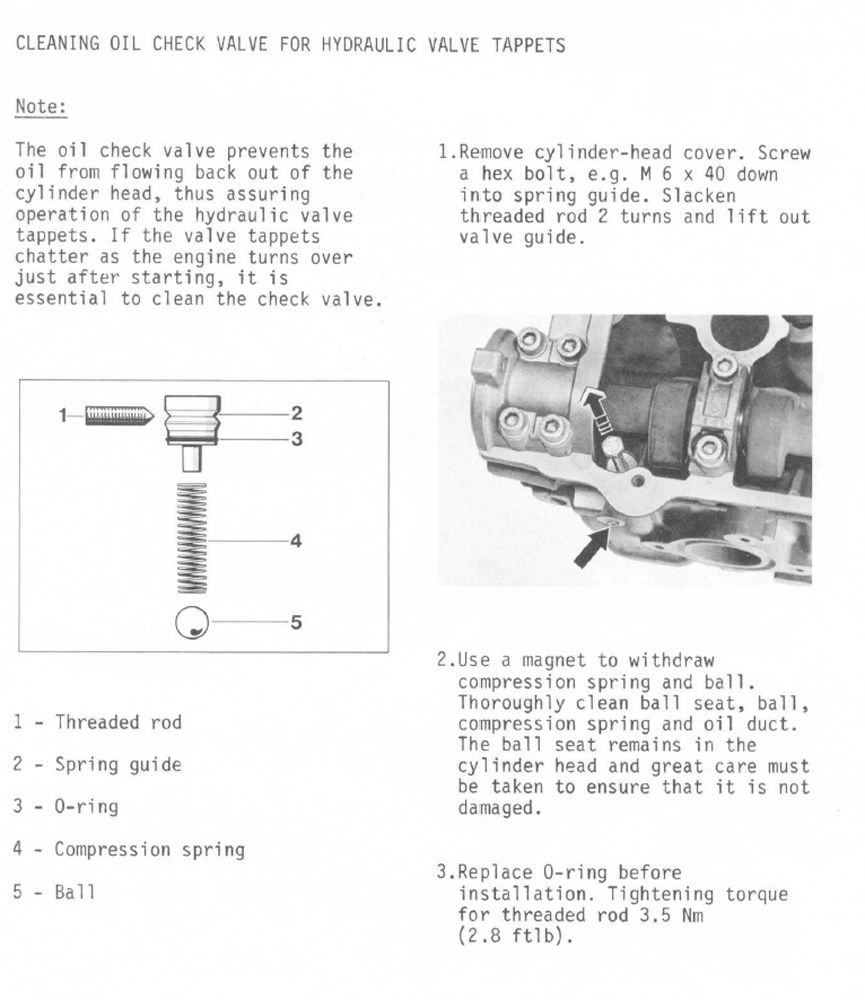

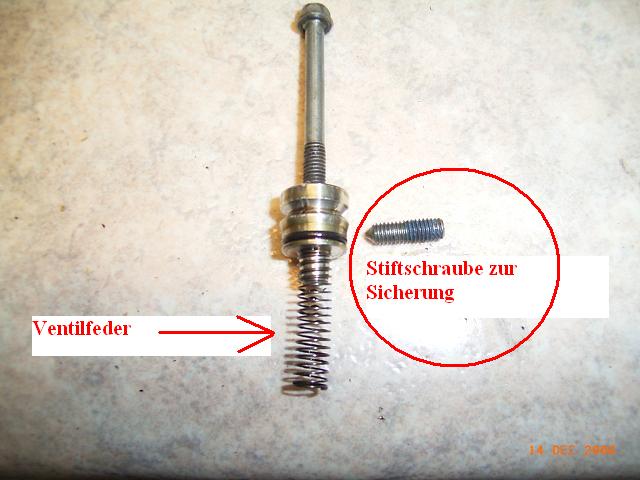

The check valve is simply a spring-loaded ball in the oil feed line that prevents oil from draining back while the engine is not running. If this check valve doesn't do its job, the oil lines in the head will be empty, and they will require a few seconds to fill when the engine is started, causing lifter tapping.

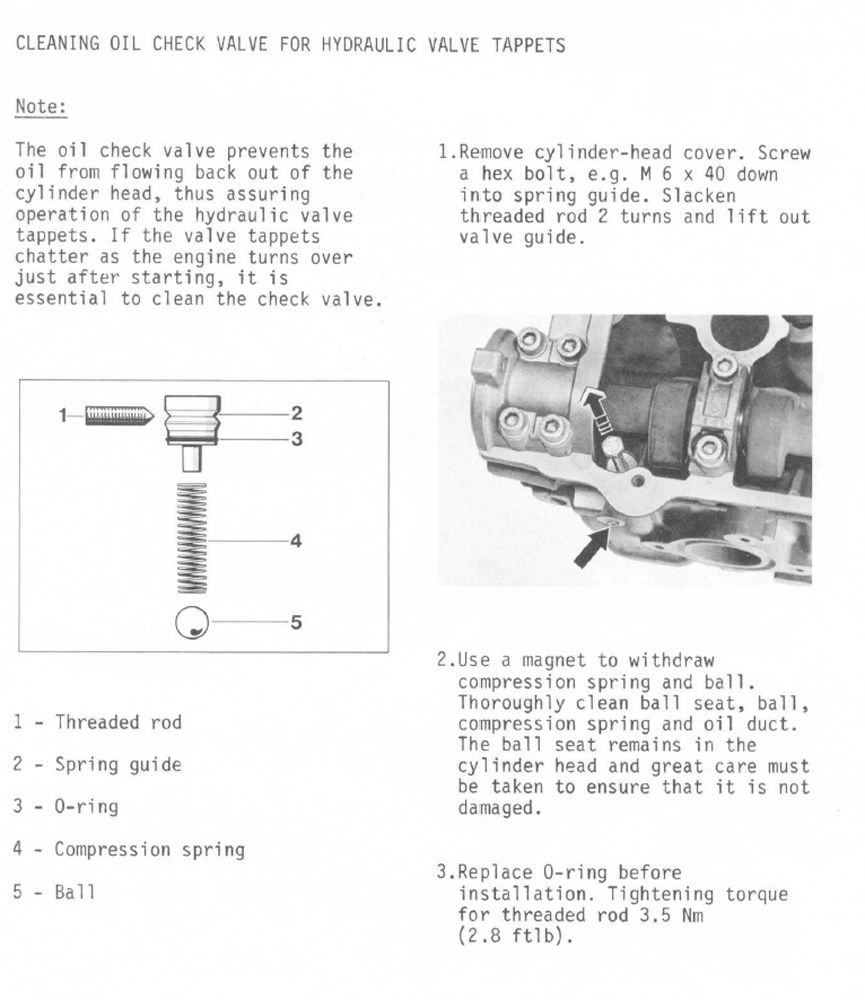

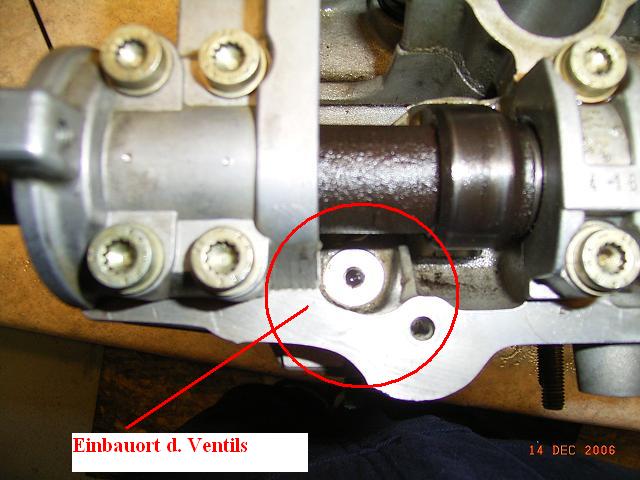

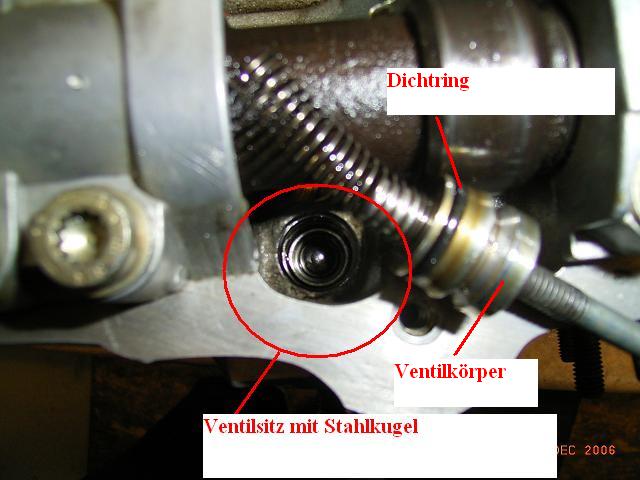

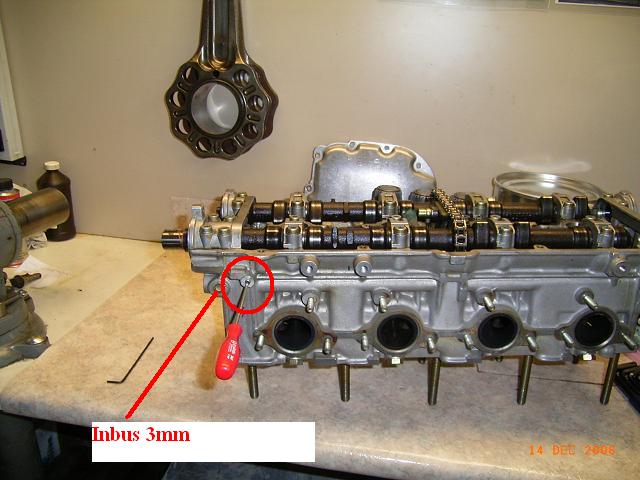

The valve is located inside the valve cover, at the lower front corner of the head. After pulling the valve cover and finding the valve, locate the locking screw that goes in from the outside of the head to the side of the valve, and loosen it about four or five turns. Screw (by hand) an M6x40 bolt gently into the valve spring guide (the only part that you can see) until it bottoms, then unscrew it two turns. Pull the spring guide out. Using a magnet, remove the spring and ball. Clean everything, being especially careful to avoid damaging the ball seat down in the hole. The book says to replace the o-ring, and it would be a good idea to do so, especially if it is hardened.

Reassemble. The threaded rod that screws into the side to retain the valve should be tightened to 2.8 ft/lb, which isn't much!

If you do this, there would obviously be a lot of WYAITs (While You Are In There, to our newer members), such as new valve cover gaskets, a careful inspection, etc.

Wally Plumley

928 Specialists

======

At 07:41 AM 12/4/2003, Curt Hinchcliffe wrote:

>First, where would I get new oil check valves? I have a tick in each head. I've tried the detergent oils to no avail. I assume the oil check valves are bad. How many in each head? Where can I get them?

IF the ticking is a lifter, and IF it occurs only for the first few seconds after starting, then cleaning the oil drain-back check valves might help. You normally only need to clean them, as there is virtually no wear involved.

In the unlikely case that you do need to replace the valves, we can furnish them, along with ANY other part available from Porsche for your 928.

One valve per head, accessed by removing the cam covers - which isn't a

trivial task.

This leakage rarely gets on the timing belt.

Wally Plumley

928 Specialists

======

Ok, in German, but pictures say it all....

Part numbers:

928-104-121-00 Valve Seat

N 25 069 2 Ball

====

if you do take the check valve apart, make sure to test to see if the lower seat

portion is indeed staked in place.

If the seat moves then it can possibly be lifted by oil pressure and thus cut

off the flow of oil to the head then the cams will seize.

NOTE the seat lies under the Ball.

If yours is loose then remove it, clean the surfaces use some green loctite and

drop it back into place, then stake the edges.

The primary function of the check valves is to stop the oil from flowing

backwards into the pan, when the engine is shut off.

The rubber pucks with pins can fall out and cause a loss of pressure to the

head.

For the best possible chance of removing the threaded rod, I suggest to drain

the block first, then you can use a heat gun to heat the area.

if you leave the coolant in the block it will not be able to be heated hot

enough to free the rod