Jay , as you point out ..." Basically put...imagine the engine as

nothing

more than an air pump, quite

literally. Anything that one can do to ease the restrictions on air flow

through the engine is beneficial both from a power and efficiency

perspective. That being said, the real purpose of the muffler system is

merely to reduce the audible noise level to an acceptable level - "........

We are looking at an "air pump" but the introduction of a fuel charge

into

the "pump" makes it much more complicated , and do not overlook the

need to

"exhaust" the burned air/fuel residue before charging it with air and

fuel

for the next explosion . The most efficient engines operate over a very

narrow RPM range , to get an engine to start idle at 750 then make power to

7,000 rpm requires many compromises . The length of the intake runners

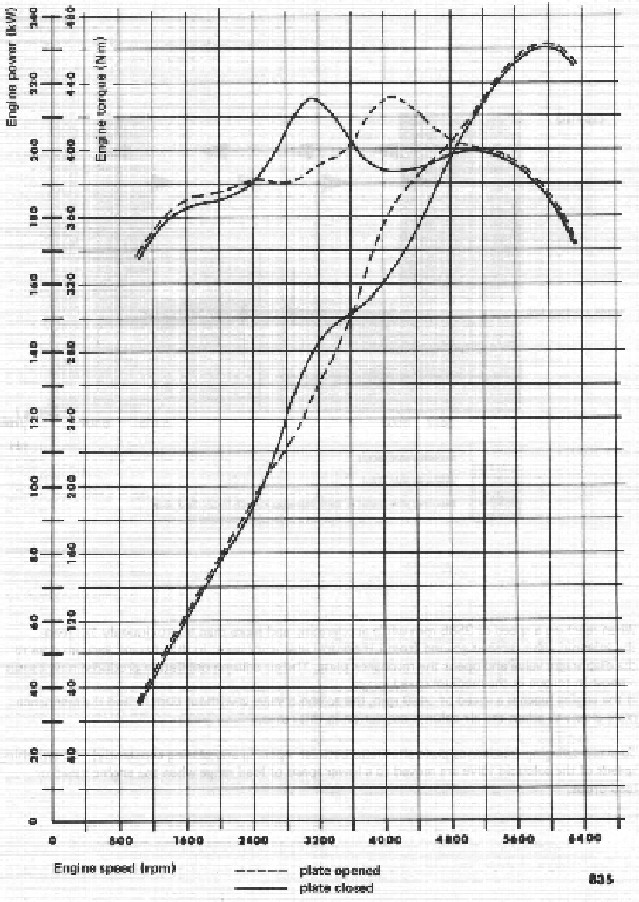

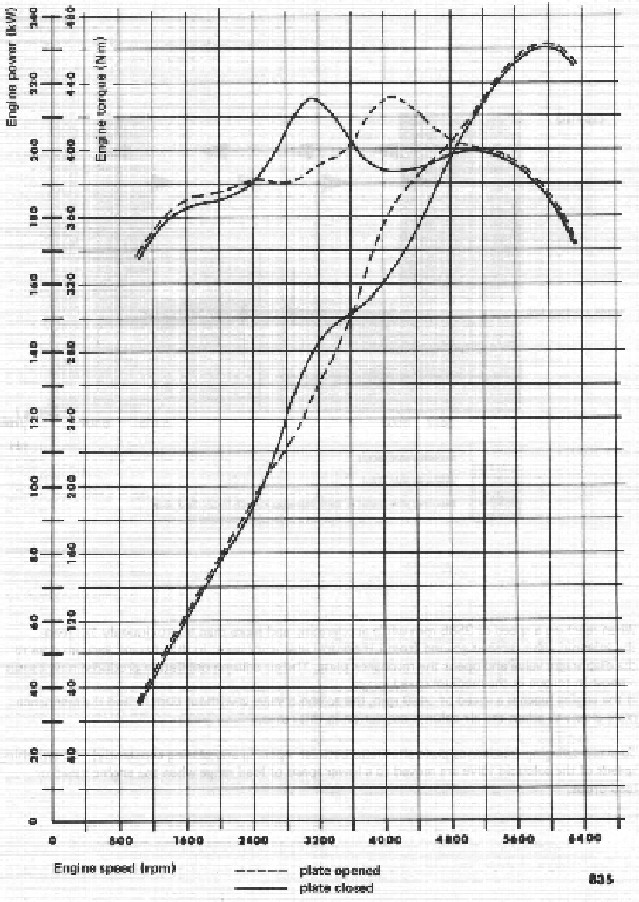

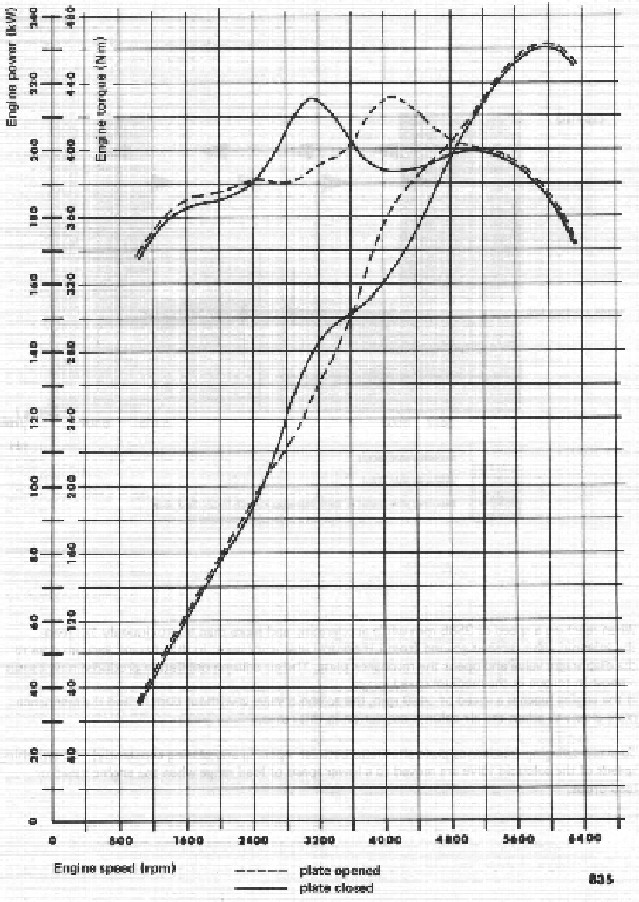

maximizes power at a specific narrow rpm range , the S-4 Flappy Valve opens

an alternative air path tuned to a different RPM hence the two torque peaks

evidenced for an S-4 . The first "natural resonance" occurs at 2,700

rpm the

second at 4,000 rpm . The same is true of exhaust systems , each exhaust

pipe length functions best at a narrow rpm range . Back pressure in the

exhaust helps to "hold "the new air/ fuel charge in the cylinder and

at

certain rpm reversion can occur to push air/fuel back into the cylinder to

"overfill" the cylinder . Small 2 stroke race boats used a trombone

exhaust

pipe , the driver manually lengthen and shortened the exhaust pipe for more

torque in the corners and more top speed HP in the straights . Some Honda

race bikes ran a throttle body , butterfly in the exhaust for similar tuning

benefits . Camshafts are a huge compromise , hence the different Vario Cam

timing arrangements used on newer engines including the 968 Porsche 4

cylinder to try to broaden the "sweet spot" . It also explains the

benefits

of advancing or retarding the camshaft timing to either raise or lower the

rpm where an engine is most efficient , a gain at one end in exchange for

losses at the other . All of the above must be factored into the engine

design to determine at what RPM it will be efficient - simply stated IT IS

NOT SIMPLE ..... an engine with no intake runners and no exhaust manifold

runs like crap --- the old Cox .049 model airplane engine is a perfect

example , a little diesel engine that chops out part of the air/fuel that is

flowing through it and pops it off with a glow plug .... Even Top Fuel

dragsters , thousands of horsepower supercharged , Nitro use exhaust pipes .

Jim Bailey

+++

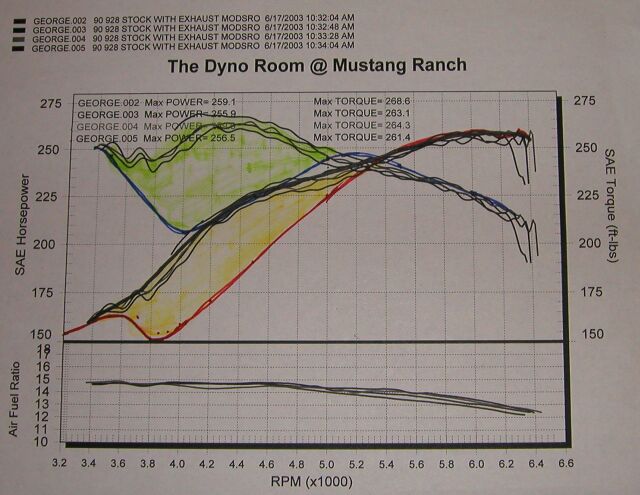

Taken from a dyno run from George Suennen. The green area is what the flappy takes care of.

==============

With the intake flap closed you have two separate intake systems closed off

from each other by the center valve/flap. Each side plenum is fed from the

common plenum underneath the manifold which is fed by the common throttle. Each

side plenum in turn feeds two cylinders on each side of the engine. Those

cylinders will generate intake pulses every 180 deg of crank rotation. That's

why two cyl from each side are required because if using all four cylinders on

one side for each side plenum, the intake pulses wouldn't be evenly spaced due

to the type of crankshaft. Without evenly spaced intake pulses, you wouldn't

have the tuned resonance characteristic of the side plenum. Parameters that

determine the frequency (RPM) of the Helmoltz tuned intake is the volume of the

plenum, the volume of all four intake runners, and the size and length of the

tube feeding the plenum. That tube is the short tube connecting the lower plenum

to each side plenum. That all works to give the torque peak (increase in VE) at

around 3000 rpm. The Helmholtz resonance gives a rather big boost to torque at

the peak, but it's pretty narrow and if left functional above the resonant RPM

area will cause a loss of torque. That's the dip after the peak and where the

flap opens to destroy the resonance in the side plenums. Then they act simply as

an air chamber to feed the intake runners which have their own resonance RPM.

The runners are not equal length so the torque (VE) increase from their tuned

lengths is distributed throughout an RPM range roughly in the 4300 to 5000 area.

The Helmholtz tuning comes in to play again at a higher RPM so the flap closes

around 5500 to help a little bit on the top end. The help at the top end is not

a lot as compared to the 3000 RPM resonance.

Louis Ott

-------------

The defaults (available in the screen shots of the SharkTuner User Manual,

available for download from my website) are :

Flappy opens at 3600rpm, flappy closes at 5880rpm. Load threshold 39 (on a scale

of 1-255).