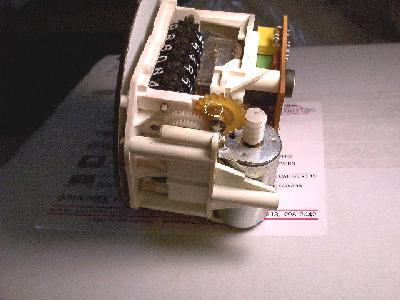

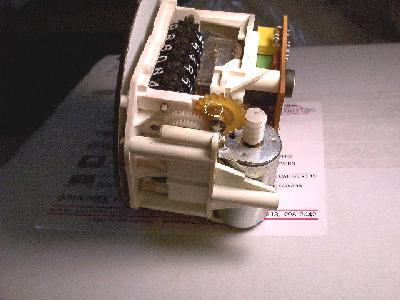

With the help of DR's trusty digital camera,

we were able to capture a picture of the odometer gear failure. I

posted a picture on my Rennlist page so anyone who hasn't seen it can

get an idea of what's going on. Go to http://members.rennlist.com/jeifert/.

The circled area shows where the small teeth get brittle and break off,

although I have been told the larger teeth can fail as well (can anyone

confirm that?). I still think there has got to be an easy way to

make a plaster mold and do an injection casting of the gear. The hard

part would be to find a suitable rubber compound that hardens to the

same spec as the OEM gear. If a successful

solution can be found, all the different sizes could be made.

JE (John Eifert) |

|

John,

How about Bondo - or Tap Plastics makes a two part liquid plastic that can

be molded and when cured is slightly flexible.

If anyone is up to this send me a gear and I will make a mold and cast up a

couple. All I ask is that someone commits to doing the testing when they

are done. Does anyone know how many different gear ratios that are used in

the 928.

Dan B.

=================

John, looking at your photo of the gear (how did you make that circle;

with a scratch awl?) it looks to me like the large teeth are in very

little danger of failing compared to the little ones. Not only are the

small ones

>, but the also have two or three times the load on them

because the larger worm mating gear has more than twice the radius.

I think the solution would be to search the PIC and BERG catalogs

wherein one can find thousands of nylon and delrin gears. Get a match

for the little gear, then file the broken one off the big gear and

fasten the new little on in its place. I don't know what pressure angle

the original gear is built to, (seems like I remember the standards as

being 9° and 12°) but nylon gears are not all that critical anyway. I

would fasten with little tiny pins about .02 inches (.5mm) in diameter.

Someone send me a broken gear! I'll work on it. Mine is not broke yet,

but if I can perfect a solution, I'll be a millionai...thousandai...hundredaire?

--jer

83sat

====================

That picture is exactly the way mine looked when it stopped working at @

115,000 miles. I took the speedo to http://www.speedometerservice.com/

in

Roswell, GA. $90+

=================

Jim

It's pretty obvious to me when looking at the gear racks in the speedo head

that they put some real time and effort into picking the individual resins

for the different gears. I do believe though that the real motivation of the

one different gear is that it is the one that allows tweaking to different

ratios but it seems that the new gear is intentionally rubbery. My guess is

that is some sort of wax loaded nylon. I think the failure mechanism is that

the carrier molding is prone to warping in the direction of loosening the

entire assembly of the ODO. When loose the gear is only half or less meshed

with it's partner and then aging does the rest of the damage.

But if you want the real culprit it's that dumb assed solenoid reset thing.

I mean what were they thinking putting an electromagnetic destruction device

right into the design. Press button... wreck ODO! That should be in

1" high

letters on the dash. Doesn't matter whether you are moving or not if the

gears aren't meshed perfectly when they crash back together after the reset

is tripped. All at the expense of looking like a cool upgrade to the normal

face mounted manual pushbutton. How gauche.

Jay K.

-----------------

Jay,

That would depend on the material used. Also, because the originals are

pretty flexible, I doubt that shrinkage of 0.5-1.0% (easily attainable)

would be an issue. Even if you _wanted_ to (or really felt the need) to hold

a ridiculous tolerance, Wally's suggestion of coating the original prior to

doing the mold would work well. Probably the use of a mold release wax would

be sufficient to account for 1.0% shrinkage. Just trying to make this easy,

affordable, timely. It seems to me that if the effort is going to be put

forth, that doing all the gears (out of a similar material) would be the

best. That way, you don't have to worry about one gear causing another to

fail. Furthermore, if _any_ gear should be made to fail, I would think the

ODO reset would be the smart choice. At least that way, the important stuff

(like the Speedo) keeps working. I agree with you 100% on the ODO reset

issue...... kinda dumb that it's designed in such a way as to destroy

things! Just goes to prove the boys at VDO (and Porsche) _are_ human after

all. ;)

Dave

===============

It's simply brilliant. I think Dan Brindle is going to give it a shot

and

I will test the product in the Zinnmetallic car. Hopefully others will

give it a shot as well.

Thanks Wally, Jay and Dave S. for your input.

JE

================

A friend from the 944 list got some 944 odo gears made up, I bought 5 or 6

and gave them to my mechanic. I will be seeing him next week and see

if

the 944 gear is the same as the 928 gear. I don't have a 944 gear out to

compare to the broken 928 gear, and vice versa for him, now. I'll let

everyone know what's up.

===================

The questions are, who made up the gears for him (professional shop or

enthusiast), what process was used, what was the material used, how many have

been installed and how have they held up?

JE

===================

Everyone,

I have had a bad odometer for over a year now in my 1984 928s. The first time I

took it apart, I found the odometer gear that meshes with the worm gear on the

odometer motor disintegrated. I replaced this with a new gear which worked for

about 75 miles and then stopped. When I took it apart, it seems the new gear did

not mesh with the other gears quite right. I straightened some teeth and it

worked again for about 75 miles then stopped. I bought another gear from another

company a few months later with the same result, works for about 75 miles and

then stops. I can't see any other problems but every time I take the gear train

apart, it works for a while and stops. Anyone else experienced this or have any

ideas?

Once it stops, nothing gets it going again except taking the speedometer out and

working the gears. Thanks.

Chris Foreman

========

Chris,

This is a common problem. There are two reasons the gear fails. The first is

from age and deterioration. The second is from binding. Moisture can corrode or

rust the shafts holding the odometer in place. The rust creates resistance,

which ends up binding the gears and will quickly wear out a new gear.

The solution is to disassemble the odometer and take some very fine sandpaper or

steel wool to the shafts. There are two I believe. It takes a little patience,

but since you have been in there you should not have much trouble. The odometer

should turn freely when you are finished. You can check it manually before

installing the gear.

Good luck

Dan the Pod Guy

Portia's Parts