Hello all,

After 3 months of work, I finally got to drive my 928 today! It's

running

great, but I just discovered yet another STUPID mistake I made.

While

installing the tensioner, I must have let the gasket get out of alignment,

because I can see an inch or so of it to the left side of the tensioner.

Needless to say, it's leaking a little gear oil. My problem is that

I

drove the car in to work today (15 minute drive), and didn't discover the

problem until I got here. Is it safe to drive it back home?

I would

think so since the oil doesn't directly apply the tension, but I don't want

to take any chances.

Thanks!

Randy

============

The oil in the tensioner serves as a shock absorber. Lots of older 928s

probably no longer have oil in the tensioner and are running just fine. I

would have the belt retensioned, then repair the broken gasket the next

time the belt is replaced. YMMV.

~ Merry motoring ~

Ed Ruiz

============

At 10:54 AM 10/9/00 +0000, Ed Ruiz wrote:

>The oil in the tensioner serves as a shock absorber. Lots of older

928s probably no longer have oil in the tensioner and are running just fine.

I would have the belt retensioned, then repair the broken gasket the next

time the belt is replaced. YMMV.

>

>~ Merry motoring ~

==============

I disagree. The oil has three functions in the tensioner:

Lubrication. The belt causes the tensioner arm to flutter continuously.

With no lubrication, the $600 tensioner will wear out.

Dampening. The oil helps to dampen the fluttering of the tensioner and to

maintain tension during such movement. No oil means more fluttering and

more wear on all of the rollers, pumps and the belt.

Heat transfer. The oil transfers heat from the block to the bimetallic

Belleville washers that maintain belt tension. Less heat transfer means

that the tensioner can't control the belt tension as well when the engine

warms up.

While the short trip home is not a problem, I would suggest that it is

better to fix the problem now, rather than accept 40 - 60,000 miles of

sub-standard performance and damage to the tensioner and belt system.

Wally

=============

At 05:05 PM 6/18/01, Tony H wrote:

>ok, to the BTDT's or those in the know.

>

I am in the process of tearing apart my tensioner, actually it is all apart now. Not knowing what the PO had really done to this car I need to

know if the washers inside the tensioner need to be "set up" in a

certain

way. I took mine apart to find SLUDGE ..DIRT ..and lots of it.

Just a thick gooey substance caked around the washers and on the tensioner piston.

>

Do these washers have to be assembled on the tensioner piston in a certain manner ...seams to me they do. Mine were arranged so a series of

washers were grouped together, then at the end of each group the CONVEX surface of each washer touched, creating a wider gap than seen in the group of washers together. I have pictures that I will post to clear up what I mean. but for now I need to know about how the washers are placed.

Depends upon the model year of your car.

If you have 40 bimetallic Belville washers:

))))) ((((( ))))) ((((( ))))) ((((( ))))) (((((

If you have 35 bimetallic Belville washers:

((((( ))))) ((((( ))))) ((((( ))))) (((((

As shown on page 15-22 of the shop manual.

Wally Plumley

928 Specialists

===================

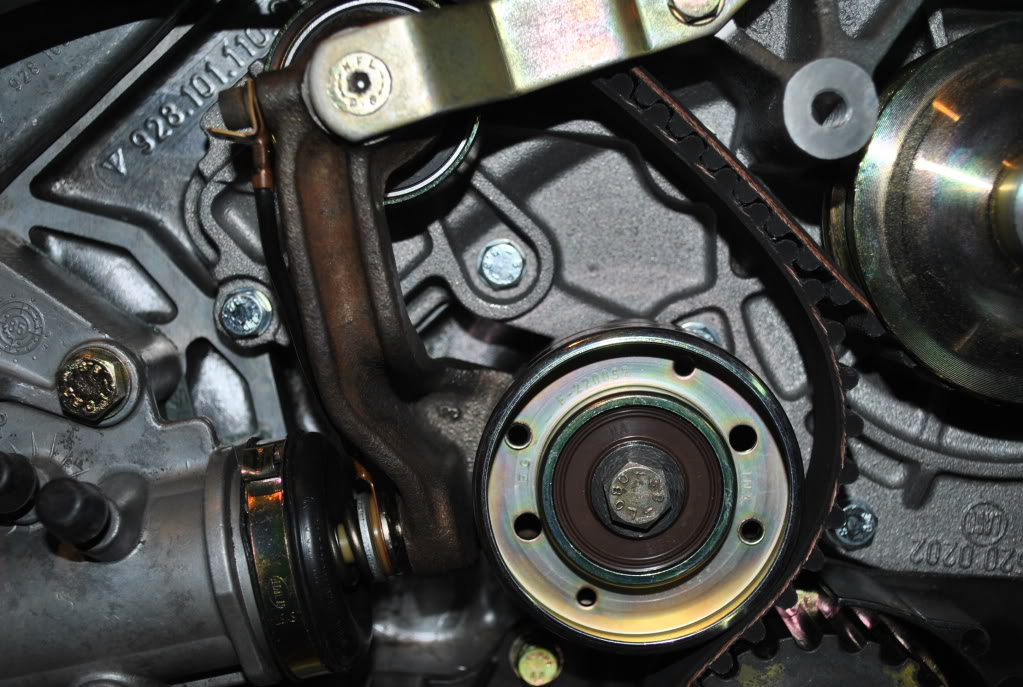

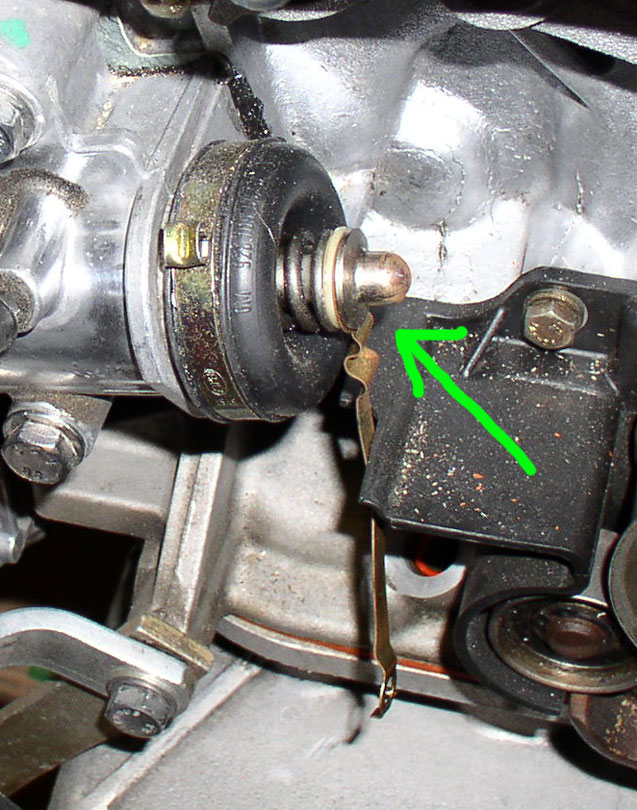

Whether the strip touches the arm has noting to do with the warning. There

is a short, stout (sort a like me) coil spring around a nylon insulator on

the tensioner push rod. When there is sufficient belt tension, the coil

spring is fully compressed, and the metal strip (and the tensioner arm) are

grounded thru the tensioner push rod.

When the belt tension is inadequate, the coil spring can expand, pushing

the metal strip away from the tensioner push rod. Since the tensioner arm

is insulated from the engine by the nylon arm bushings (you did check

those, didn't you?), this breaks the ground connection. The warning

computer then sets the belt tension warning.

On the late models, the top hole or nipple is the filler, the lower one

closer to the block is the bleed hole or nipple.

Wally Plumley

928 Specialists

==============

<snip from previous posts>

You are both correct. The oil does provide a dampening effect that helps to keep the spring pack from creating belt slap at some rpms that would create a constructive interference pattern. But it is the lubricating effect that keeps the tensioner assembly reading properly. A dry tensioner will bind and mess with tension. It is not true that there is any hydraulic effect other than dampening. The spring packs provide ALL of the pressure that tensions the belt. Mostly what the oil is does is provide a thermal transfer to the springs. Air is an insulator. Secondary is lubrication. Third is dampening.

Just to review for any newbies the tensioner is not automatic it must be manually set to the correct belt tension periodically. Especially after a new belt is installed as the initial stretching/settling is somewhat unpredictable.

Also, on early cars there is no way to refill the tensioner without removing the belt and arm and actually pouring 90 weight in. Later cars have fill, drain, bleed ports. I actually believe that grease would work just fine. It would have a tendency to stay in with a ripped boot and would provide all the thermal transfer, lubrication and dampening effect. But it could alter the dampening characteristics and it would certainly start out hard as a rock on cold days. But it would probably work fine. I haven't tried it, but if I had thought of it I might have :) A tensioner boot is all that is normally required for a rebuild an a few ounces of hypoid oil. don't let a mechanic tell you that you need a whole new...multi hundred dollar tensioner assembly. There is almost no way for it to actually wear out. It just needs to be taken apart, cleaned and put back together normally.

Jay Kempf

==========

At 12:41 PM 9/9/02, sertan wrote:

> Is the tensioner boot for dust or is it to keep the oil inside?

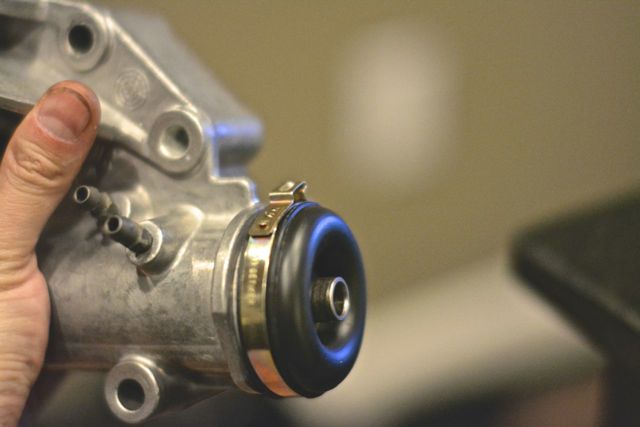

The tensioner boot is an important part of the timing belt system. The boot

keeps the oil inside the tensioner, and should be replace every time that

the timing belt is replaced.

Wally Plumley

928 Specialists

===========

> Will someone please tell me how to remove the valve carrier from the tensioner so that I can replace the o ring. I can push it a small distance through the adjusting bolt hole with a screwdriver but then hit a "wall". Don't want to break anything. TIA. T.T.

Of course, mine just pushed out easily, but I encountered the same

resistance you are reporting when I helped another Shark owner do his last

weekend. Push the piston back down into the bore and spray the bore with

brake cleaner and try to scrub it out. You may notice some crud on the bore

that is obstructing the piston's removal. Spray some in the adjustment bolt

hole too. Spray some penetrating lube down the bore and in the adjustment

bolt hole and try again. A few back and forth and it should come out with

very modest force. After it came out there was still quite a bit of crud to

clean out of the bore and the o-ring was found to be rock hard. It will

come out.

Bill

89 S4

===========

It doesn't have to be gear oil, it can be motor oil also, *BUT*, it should be

filled, as the presence and temperature of the oil causes the washers to

function correctly in expanding to take up slack in the belt, i.e., it's easier

to throw a belt of jump teeth when the tensioner is not filled. Oil transfers

heat from the block to the belleville washers which maintain proper tension on

the belt.

wk

===========

A couple of minor points on Dan's comments:

I agree that it is better to fill the tensioner after the belt is properly

tensioned. The tensioner should be filled with oil, and any movement varies the

volume within the tensioner. The boot must accommodate the change in volume, and

the closer to normal volume when you fill it, the better.

The original Manual instructions say to fill the tensioner with 90 wt gear oil.

There is a later bulletin that says to use engine oil. In my opinion, either

will work, but engine oil is usually more available for most people, and smells

better. There is very little difference in viscosity between 90 wt gear oil and

engine oil, and there are no heavy sliding loads in the tensioner that would

require the EP additives in the gear oil.

The oil serves three purposes:

- Transfer of heat from the block to the bimetallic Belleville washers, so that

belt tension may be held almost constant when the aluminum block and heads

expand from heat.

- Damping of belt flutter due to varying loads.

- Lubrication of the tensioner.

I do not agree that white lube would work well. I would be very concerned that

voids would develop in the lube, especially with the belt flutter that the

tensioner is supposed to damp.

I suspect that Mark may not have had the bleeder screw open enough when he blew

the boot off.

The tensioner should be rebuilt every time that the belt is replaced.

Dan is correct on the tensioner arm bushings - something that is often

overlooked. They should be replaced if there is any perceptible play in the arm.

Wally Plumley

928 Specialists

=====

Cam Belt tension warning, NOT

--------------------------------------------------------------------------------

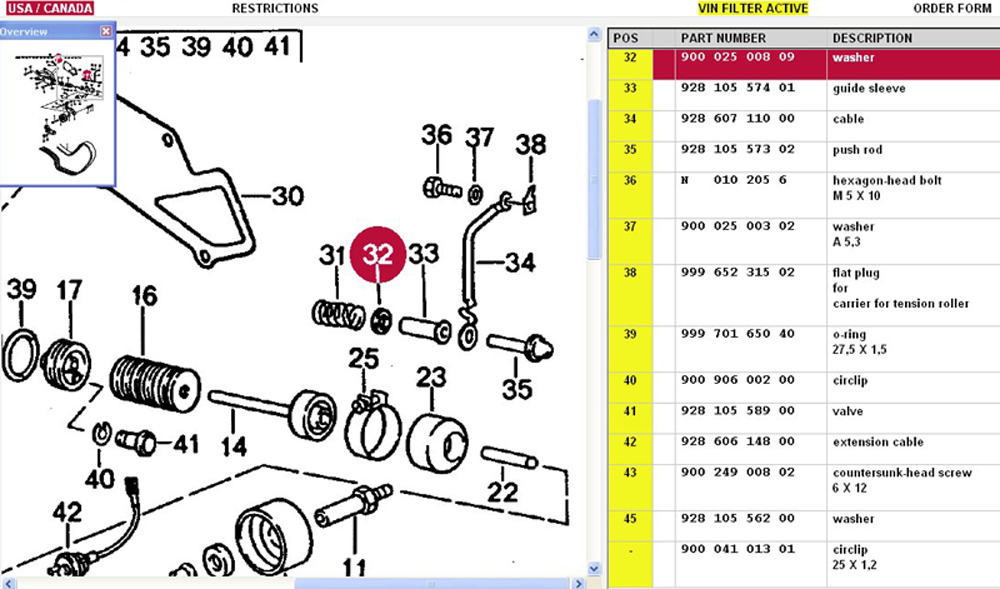

I am posting this because I have seen it twice in the last 2 weeks on '93 GTS's

with the stock systems.

There is a washer in the stock cam belt tensioner system that is very easy to

lose when assembling the stock tensioner system. It is 103-10 #32 in PET P/N 900

025 008 09.

With this washer missing, the cam belt could be extremely loose before you would

see a cam belt tension light.

I normally check cam belt tension before I replace the belt. The light will come

on at ~4.0 on the 9201. Proper tension is 5.0 to 5.3. These belts were 3.5 and

2.2 on the 9201. I don't know at what tension the cam belt fails (probably no

one does), but these low tensions scare the hell out of me.

I usually "glue" the washer to the Guide Sleeve (#33) with grease or permatex #3

so it stays on during installation. It is very easy for the washer to fall off

and roll under the car undetected.

It appears that you can probably get proper tension with the washer missing

during installation, so everything seems OK, but I don't know if there is enough

room on the bolt to allow subsequent re-tensions with the washer missing.

__________________

Capt. Earl '91 GT

----

----

This washer has a bad habit of falling out, directly in to the pan you are using

to catch the coolant, when you remove the roller arm.

Sometimes you don't even know it has fallen out, so you have to make sure you

have it on reassembly.

The dimension of the part is 20.7mm OD, 2mm thick, 10.6mm ID.

__________________

http://www.928srus.com/

SeanR

----

How true this is. I can't tell you how many times I have found this washer

missing. It falls to the ground as you pull the tensioner off to rebuild it,

often unnoticed.

In a guide on how to do a timing belt job by one of our most esteemed members,

you can see that washer is there at the beginning of the job and no longer there

after the tensioner was reinstalled.

__________________

Bill

----

A quick search of PET per your excellent recommendation shows that the same

washer is used in a few places.

For the benefit of others, the most accessible of the correct ones seem to be

the 6x retaining studs on top of the front shock mounts in the engine bay, or

the front and rear bolts that hold the AC compressor to its bracket.

The correct part is 20.7mm OD, 2mm thick, 10.6mm ID.

__________________

Hilton

Timing belt Tensioner warning contact connector. This attaches to the little wire at the rear of the cover which is used to loose contact to ground, signalling a loose belt.