TC Components and Power Flow

Torque Converter Components

Impeller - The impeller is driven through the converter cover by

the engine flex plate. It is the "input" member of the converter

assembly and makes up the second half of the of the converter outer casing.

Stator - This is the stationary or "reaction" member

for torque multiplication. It controls oil flow from the impeller in the

"reduction" phase of converter operation.

Turbine - The turbine is driven by oil splashed from the

impeller. The turbine is the output member of the converter which drives the

turbine shaft of the transmission.

Damper Assembly - The Damper is welded to the converter cover. It

cushions engine shock to the direct drive shaft of the transmission.

Stator Support - The stator within the converter is splined onto

the stator support: the stationary shaft extending from the front of the

transmission pump.

Impeller Hub - The hub is a steel collar welded to the impeller

which mechanically drives the gears of the transmission pump.

The converter is supported on the stator support [5],

which is part of the transmission oil pump assembly. The impeller hub [6]

is supported by the transmission pump body bushing.

Power to the Gear Train

Depending on which gear the transmission is in, input from the engine to the

transmission is through the turbine input shaft or the direct drive shaft or a

combination of both.

- In reverse, first and second gears, the turbine input shaft transmits

torque from the turbine to the reverse clutch or forward clutch. This a

hydraulic drive, since the impeller must drive the turbine with hydraulic

oil.

- In fourth gear (overdrive), the direct drive input shaft transmits torque

to the rear (direct) clutch. This is a solid (mechanical) drive, since the

turbine is by-passed. The damper assembly drives the shaft at engine speed.

- In third gear torque is split between the two shafts. The drive torque is

about 40% hydraulic and 60% mechanical.

How the Converter Works

7

Automatic Hydraulic Clutch

In Reverse, low and second gears, the converter operates in hydraulic or soft

drive conditions. In hydraulic drive, the converter functions as an automatic

clutch (when the car is stopped) and as a torque multiplier (when engine load

requires more torque).

- The engine drives the impeller mechanically.

- The turbine is driven hydraulically by the impeller.

- The turbine drives the tube input shaft for input to the gear train.

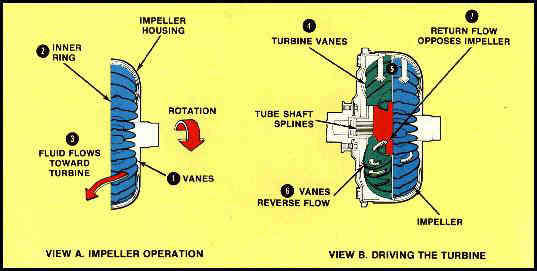

Impeller Pumps Fluid

The purpose of the impeller is to put the fluid in motion. Inside the impeller

housing many curved vanes, along with an inner ring, form passages for the fluid

to flow through. The rotating impeller acts as a centrifugal pump. Fluid is

supplied by the hydraulic control system and flows into the passages between the

vanes [1]. When the impeller turns, the vanes

accelerate the fluid and centrifugal force pushes the fluid outward so that it

is discharged from openings around the inner ring [2].

The curvature of the impeller vanes directs the fluid toward the turbine, and in

the same direction as impeller rotation [3].

Rotary Force on the Turbine

As shown in View B (above), the turbine vanes [4]

in the turbine are curved opposite to the impeller. The impact of the moving

fluid on the turbine vanes [5] exerts a force that

tends to turn the turbine in the same direction as the impeller rotation. When

this force creates a great enough torque on the transmission turbine output

shaft to overcome the resistance of motion, the turbine begins to rotate.

Now the impeller and turbine are acting as a simple fluid coupling, but we

have no torque multiplication yet. To get torque multiplication, we must return

the fluid from the turbine to the impeller and accelerate the fluid again to

increase its force on the turbine.

Vanes Reverse the Flow

To get maximum force on the turbine vanes when the moving fluid strikes them,

the vanes are curved to reverse the direction of flow [6].

Less force would be obtained if the turbine deflected the fluid instead of

reversing it. At any stall condition, with the transmission in gear and the

engine running but the turbine standing still, the fluid is reversed by the

turbine vanes and pointed back to the impeller. Without the stator, any momentum

left in the fluid after it leaves the turbine [7]

would resist the rotation of the impeller.

At this point, we have a simple fluid coupling that will cause the turbine to

drive the input shaft with no torque multiplication. To gain multiplication, we

must add the reaction member or stator.

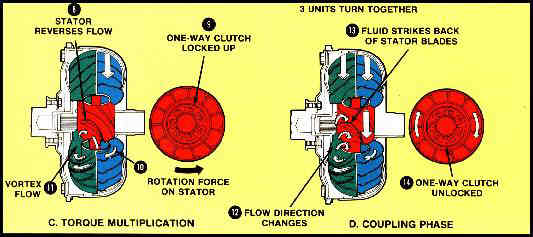

Torque Multiplication and Coupling

Torque Multiplication

When torque multiplication is required, the stator [8]

above reverses the direction of impeller rotation. A one-way clutch [9]

prevents the force of the fluid from turning the stator opposite the impeller

and turbine by holding itself motionless on the stator shaft.

As the fluid flows from the stator to the impeller, the impeller has another

opportunity to accelerate the same fluid. The fluid [10]

leaves the impeller with close twice the energy it had the first time and exerts

greater force on the turbine.

We call the flow of fluid [11] through the

impeller, to the turbine, through the stator, and back through the impeller the

vortex flow. At high impeller speed and low turbine speed. the vortex flow

velocity is the sum of the impeller produced velocity, plus the velocity of the

fluid returning from the turbine and stator. It is vortex flow that gives us

torque multiplication.

By torque multiplication, we mean that there is more torque on the turbine

shaft than the engine is putting out because the vortex fluid is accelerated

more than once. Torque multiplication is obtained at the sacrifice of turbine

rotation. Actually, it's no different from the mechanical advantage which your

get from gearing down. You gain torque by sacrificing motion.

Torque multiplication takes place anytime the turbine is turning at less than

9/10 impeller speed. At full stall, the stock AOD converter produces about

1.85-to-1 torque multiplication. As the turbine speed increases in relation to

the impeller, torque multiplication decreases.

Coupling Phase

When the coupling phase (view D above) is reached - when the turbine speed is

about 9/10 impeller speed - there is no longer any torque multiplication. The

converter is then only transmission engine torque to the gear train.

As the turbine begins to rotate and steadily picks up speed, the vortex flow

steadily looses speed because of the increasing centrifugal force acting against

the flow through the turbine. The rotating impeller produced a centrifugal force

in the fluid which caused it to flow from the center outward. The same

centrifugal force is acting in the rotating turbine, trying to prevent the fluid

from flowing inward. As the vortex flow slows down, torque multiplication is

reduced.

As the turbine catches up with the impeller, the angle at which the fluid

leaves the turbine is constantly changing [12]. In

the coupling phase, the fluid leaving the turbine strikes back at the stator

vanes [13]. The one-way clutch unlocks [14]

and the impeller, turbine and stator turn together. Allowing the stator to

rotate freely during coupling lets the fluid moved by the impeller to flow

directly into the turbine.

Converter Automatically Adjusts Torque

Since vortex flow speed is governed by the difference between impeller and

turbine speed, the torque converter output to drive shaft torque requirements.

When drive shaft torque requirements become greater than the engine output

torque, the turbine slows down and causes an increase in vortex flow velocity

and therefore an increase in torque multiplication.