Bosch Artikel Nr. 0280 140 509

OE-Nr. BMW 13411286065 OE-Nr. PORSCHE 928 606 161

00

Tom wrote:

Can anyone elaborate on the theory of operation of the following 2 items?

Or, point me toward some reference material?

Idle stabilizer (32V engines)

Flappy valve (32 V engines)

==================

The "idle stabilizer" is a variable valve that controls the air flow

into the engine at idle.

Most (maybe all, I don't know) are made by Bosch and are "torque

motors" - what looks like an

electric motor, but with the armature constrained by a clock spring so it can

only rotate

about 1/4 rev. It is attached to a rotary valve that controls the air

flow. More current

means more rotation, hence more air flow and the idle speeds up. Problem

is the clearance in

the valve is very small and small dirt particles can cause friction. The

computer says "speed

up" and applies more current, but the motor sticks. Engine slows down

more, more current is

applied and suddenly it breaks loose, opens too far, computer reduces current,

valve sticks

open, well you get the picture. Result: idle surge, sometimes enough to

stall, always

annoying. Others like Hitachi have tried to make this type of thing work,

never with any

success. Almost all new cars have stepper motors working a valve on a lead

screw. Reliable,

but more complicated.

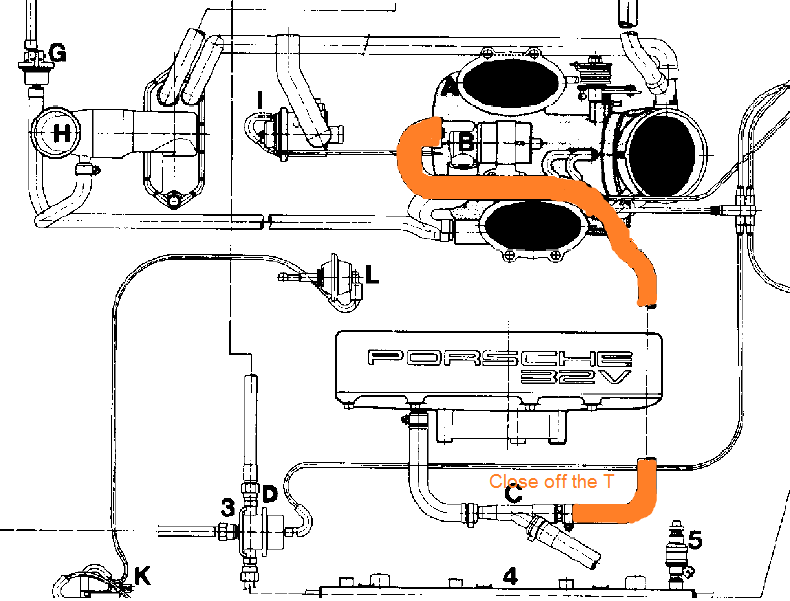

The "flappy" (where did it get that name, anyway?) is a butterfly

valve that changes the

geometry of the intake manifold. At low rpm - below 4,000 - the valve is

closed, separating

the two halves of the manifold into essentially two 4 cylinder engines.

The tuning is then

optimized for low rpm torque. Above the set speed the valve opens,

connecting the two plenums

together pretty much eliminating the Helmholz effect and tuning the engine for

high rpm

torque. The valve is operated by a vacuum diaphragm hidden (of course)

below the central

manifold which, in turn, is controlled by a solenoid valve pulling vacuum from

the reservoir

and energized from the engine controller. A lot of new production engines

have this feature.

Note that each plenum is not connected to the cylinders of that side of the

engine, but is

connected to the end two cylinders of one bank and the middle two of the other

bank, which is

what it takes to get a 4 cylinder even-firing engine.

Hope that helps.

Gary Casey

===============

As has been pointed out the

idle stabilizer does what the name implies -- it

has the same effect as though someone were pushing and releasing the

accelerator pedal it is controlled by a circuit in the L H injection brain

and tries to maintain the programmed idle speed regardless of whether the

a/c is running , etc. -

Jim Bailey

928 International

===============

Hi Gary,

You must either be a technical writer or a teacher/professor. That was the

best and most understandable description I have seen. I now understand what

is happening and why the surging happens. Others on this list also gave

answers for which I am thankful, but assumed or took for granted that I knew

more about this valve than I do. The explanation of the armature constraint

and the increased current to overcome the friction/blockage now explains

perfectly the surge phenomenon. It always seemed to me that 'something' was

constantly overcorrecting, causing the idle fluctuation, but couldn't

understand what.

As a side note, I took the suggestion from all the great listers that

replied yesterday. I removed the vacuum line running to the

stabilizer / actuator and doused it with WD40 and let it sit for a few

minutes. I then disconnected the ground strap.

After connecting the hose and the strap back, my problem went away within a

couple of minutes of running and has not returned. Thank you all.

The only remaining engine problem I have now is a total lack of low end

power. It is almost as though I have an extremely lean or rich situation and

I have a terrible lag until I reach about 2000 - 2300 rpm. I checked the

'Flappy' and it is working fine. It Blips on startup, closes and remains so

until high RPM (about 4000). This was a mystery when I first bought the car

and even after replacing rotors, caps, wires, injector seals etc.. it still

continues.

Again, many thanks to all the great knowledgeable folks who replied.

Tom Csibor

==============

Eric-

No idle adjustments on an S4.

In as far as idle controller....some have had luck by squirting a bit of WD-40 into the intake vacuum line. This was recently done by Chris with good results.

Basically....

Locate the throttle linkage on the drivers side. Directly below the linkage, you will see a black hose that runs fore to aft along the manifold lower edge. Locate the 'y' fitting in the hose. Disconnect where the 'y' connects to the hose that goes under the manifold (aft end of the manifold). Squirt WD-40 into the hose that leads under the manifold. Re-assemble the fittings and let sit for a few hours. (I've never done this...just going off previous posts.) HTH-

Jay

'87 S4 Auto

==============

John, et al, I used what I feel to be a better penetrating oil for my idle stabilizer problem. I've been using "Kroil" in the aviation industry for years, and it is far superior to WD-40. Also, I helped it along the path down the tube with low pressure compressed air. Did it a second time a few hours later, and let the car sit overnight. The next morning the car started and idled great. Still idling great, but we'll see how long it lasts. I still plan to try Wally's procedure of turning off, and restarting the car while driving @ 45mph. Good luck to us all,

Chris lockhart

'89 928GT

==============

At 08:30 PM 7/13/01, Greg Klanderman wrote:

>Jim,

>

>Thanks, that's what I was figuring, though I've seen numerous posts and OC tips regarding the vacuum line to the stabilizer.

>

>So where exactly am I supposed to spray this WD40? The tip seems to indicate the thin vacuum line that goes from the four-way under the >intake. Looking at the OC tips regarding the flappy, I'm guessing this line actually goes to the flappy solenoid valve on the driver side cam cover and then to the flappy actuator. It seems like that pathway won't even be open unless I'm above 4000 rpm. Can someone clarify this procedure, or is it total myth? I've seen this referred to as a DR suggestion - is he listening?

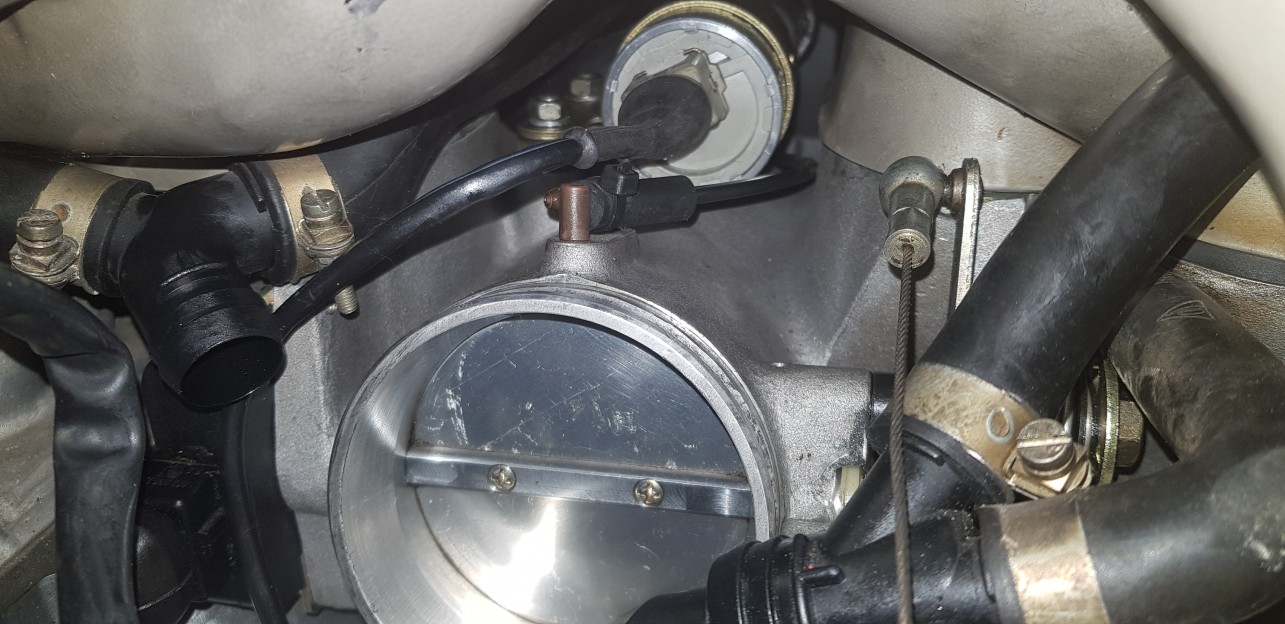

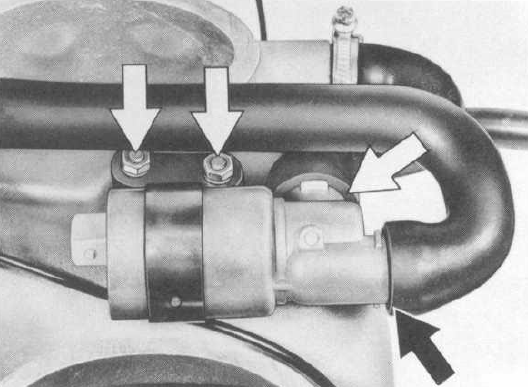

The unit in question, which goes by a number of aliases (idle stabilizer, rotary idle actuator, idle speed actuator), is the ECU-controlled servo that controls the idle speed on S4 - up cars. It does this by regulating the flow of air from a fitting before the throttle to a fitting on the intake manifold after the throttle. Thus, the idle actuator or idle stabilizer acts as a computer-controlled bypass valve around the throttle, controlling the idle speed. The actuator valve sometimes begins to stick due to crud build-up.

The clearest illustration is on page 24-216 in the shop manual. There is a fitting in the side of the large tube that connects the MAF sensor to the throttle body. Air that flows from this fitting thus has passed thru the MAF sensor (and is "measured air"), but has not passed thru the throttle (and is not "controlled air"). There is a Tee in the air hose attached to this fitting. One leg of the Tee runs to the inlet side of the idle actuator, furnishing the bypass air to control the idle speed. The other leg of the Tee runs to the vacuum ejector, the slant-Tee vacuum fitting located on the right side of the intake, near the throttle cable quadrant.

(This fitting is a vacuum booster, utilizing air flow from the Tee and large inlet tube into the intake manifold to furnish boosted vacuum to the vacuum brake booster.)

There are three lines on this slant-Tee fitting. One runs to the vacuum brake booster; one runs to the intake manifold plenum; and one runs under the manifold. If you disconnect the input tube (the one that runs under the manifold to the Tee) and block the opening in the fitting, then spray a solvent, such as WD40, into the tube running under the manifold, the air flow into the idle actuator will carry some of the solvent into the valve section of the actuator, where it may or may not remove some of the crud and reduce the sticking.

If you are desperate enough, you can pull the air filter housing and MAF sensor off, clamp the inlet hose shut at the slant-Tee, and spray solvent into the fitting in the large inlet tube with the engine idling. This will get a heavier dosage of solvent to the idle actuator valve mechanism.

Wally Plumley

928 Specialists

==================

Next to the throttle linkage is a 3-way splitter - one line runs to the brake booster, one into the side of the intake, and one down under the intake at the rear. Undo the hose going down under the intake at the rear and spray a bunch of the WD-40 in there (engine off - I guess you could run the engine but I didn't try it that way). This hose feeds in just ahead of the throttle body and with a little luck the WD-40 will be pulled in/around/through the idle stabilizer and give it a lube. But given the heat, this is reportedly a temporary fix (maybe 2 weeks) but does help you localize the problem. You'll get some funny exhaust smell when the engine burns the WD-40.

Now to be clear, the flappy (intake air tuner flap) is a different component altogether from the idle stabilizer. One stabilizes the idle by allowing air around a closed throttle body butterfly valve. The other tunes the intake for better breathing at high RPMs.

John Pirtle

87 a/t 125k

==============

Okay Gang-

Besides the WD-40 trick, check to see if your Idle Stabilizer is actually working on an 87+ models as follows-

Disconnect the LH wiring harness from the LH Brain,

Use a short piece of wire to jumper contacts 17 to 21 (by rotating the LH plug in such that the locking ear piece is pointed left with the locking handle pointing right, the bottom right most point is #1). Using a longer piece of wire, insert it into point #33. Route this to the engine bay so you'll be able to listen to the Idle Stabilizer. Touch the free end to a bolt associated with the engine brace. You should here the Idle Stabilizer swing full open. Remove the wire and you should here a prompt 'thunk' signifying the stop position.

This should help you determine if you have a stuck/sticky Idle Stabilizer (or help free it up using the WD-40 trick).

hth-

Jay

87 S4 Auto

-----------------

Idle Valve

Original part number: