First tip: print the procedure from John's excellent website:

http://members.rennlist.com/pirtle/tbelt.html

=============

Here's a Timing belt replacement tip passed onto me by Pete Loedding.

Before taking the tension off the old belt, set it to the TDC position as

detailed in the Service Manuals. (Make sure all the marks line up as they

should.) Then, turn the crank to the 45 degree mark. Make a paint

mark on

each of the cam-shaft gears directly across the reference marks. Rotate

the crank again to 45 degree to verify that the new marks line up with the

reference points. If so, place the engine lock in place and remove and

reinstall the belt at the 45 degree mark.

The reason for doing it this way is to avoid any movement of the cams,

since there is no additional spring load on any of the valves while at the

45 degree position. YMMV.

~ Merry motoring ~

Ed Ruiz

=============

Dear fellow sharksters:

After washing the GT, I decided to check the T-belt

tension with the J. Kemp re-make of the original

tensioner tool.

Unlike the pre-S models, the GT does have a bit more

to remove in order to gain access to check the T-belt.

The first thing I did was remove the fan shroud with

its two electric fans. Once that was out of the way,

it was easy to get to nearly everything at the front

of the engine. I then removed the right side

distributor and then the two bolts that hold the right

side T-belt access cover in place. I turned the

engine over by the crank pully bolt (clockwise) to

O/T.

The belt tension was just within specs, so I added a bit more. After each check and retensioning, I

rotated the crank two full rotations back to O/T.

Once the tension was just a bit over half-way in the

window, I set the lock bolt, then buttoned it all back

up. Total time for the job was about an hour.

Merry motoring, ~ Ed ~

=============

>What is the purpose of rotating the cams 45 degree before locking the

crank and installing the belt? I am doing this procedure this weekend if all prevails.

The 45 deg position (on the crank, not the cams) is the only position where

you can be assured that there will be no valve-to-piston contact when you

rotate the cams independently. This is the position for taking the cams off

and putting them back, or for changing the timing belt.

Wally Plumley

=============

Hi Johnny,

>My belt is broken and my favorite car just got four cylinders running!! How do I change the belt, rotors direction etc...??

Workshop Manual, Volume 1A, Section 28 , Pages 48, 48a, 48b... or you can

call me for verbal instructions, it is not hard at all.

>Rotor number one is ok of course but what will be the position of the other

one.

> It is possible to check this out by controlling the pistons but I want to

know if there is an >easier way for instance rotor two related the rotor

one or something like that

Remove the 2 distributor caps, while facing the engine look down at the 2

"circles" where the caps mount, the rear (primary) will have a notch

on the

perimeter at approx. 4 o'clock, the front (secondary) will have a notch at

approx. the 10 o'clock position. Rotate the engine (27mm socket via crank

bolt) clockwise till the primary rotor lines up with the 4 o'clock notch.

When you replace the belt, position the secondary rotor to the 10 o'clock

position.

David Roberts

928 SPECIALISTS

===============================

Hi all,

I am in the middle of replacing the timing belt on my 87 S4 and I just

realized that I made a mistake. When I marked my cam sprockets at 45

degrees, I didn't rotate the crankshaft past TDC before stopping at the 45

degree mark. In other words, I was at TDC and I rotated the crankshaft

clockwise to 45 degrees. What has occurred is that now that I have the belt

off, the left (drivers side) camshaft has rotated approximately one tooth

away from where I made the erroneous 45 degree mark, it doesn't appear to

turn easily by hand.

Can I just rotate the camshaft back to where it should be relative to the

other camshaft and crankshaft? Do I have to rotate it just the one tooth

width or do I have to do almost one complete revolution?

Thanks

Jamie Howton

============

Hi Jamie,

The direction you turn the cams or crank should only matter when you have the

belt on. With the belt on if you go CCW you will overload the tensioner.

I think you are fine with what you did. The valve springs will tend to pull

the cams one way or another when the belt is taken off. I wouldn't move the

crank at this point as you would probably hit a valve or three while doing it.

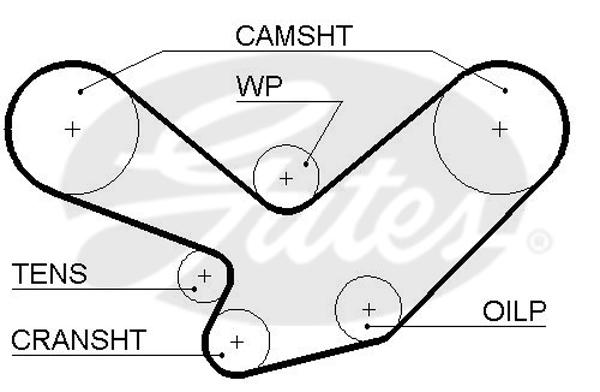

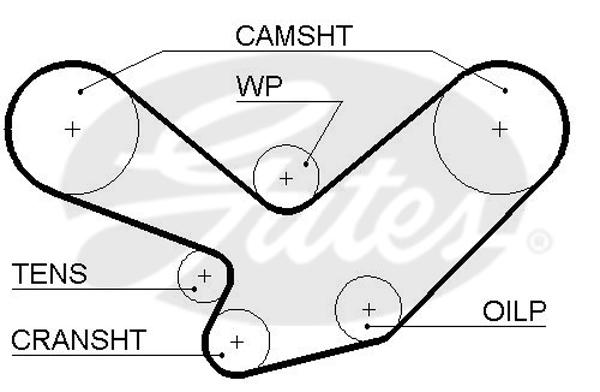

Put the crank at 45 deg. from the closest direction. put the belt on the tensioner,

past the crank and oil pump, up over the left side cam. Line it up on your mark

while doing it. past the water pump to the right cam, lining it up as you put

the belt on. (you will probably need a wrench on the cam to move it easily,

those springs are tough. snug up the tensioner and look at all your marks. If

they look good walk the crank around by hand and check on the second rev of

the crank where the marks are. if they are all where they belong (the factory

TDC ones) then tension the belt properly and you should be set.

I always am nervous in situations like this and do at least a triple check

of everything before lighting the fire though.

Grasser

=========================

Ryan,

You are in fine shape here. There is no big thing on a 16 valve engine

setting the belt. You do not need to worry about bending the valves

because

this is a non interference engine. If it wasn't setting the crank to TDC

and locking and then turning the cams would be bad and you would encounter

resistance in turning them as the valves opened and contacted the pistons.

On a four cycle engine - at least everyone I have seen the crank makes two

revolutions for every revolution of the cam. It is no different on a

Porsche - although I hear they are working on changing that.

So take off the distributor cap and find TDC with the rotor pointing to

cylinder 1. Put the distributor cap back on so you do not damage

anything..

Next set the cams to the timing mark. - You should only turn the cams in

the clockwise direction or you take a chance of loosening the cam drive nut.

The cams will spring back because they are now loaded. So the best bet is

to get the cams just before TDC so that they are not yet spring loaded.

Take the timing belt and feed it around the crank and oil pump. The teeth

on the crank will lock the belt in place. It is easier with a second

person

to keep a little tension on the back side of the belt in the initial stages

so it does not slip on the crank.

Work the belt up over the left cam. Just before you set the belt to the

left cam crank the cam up to the timing mark. Lock the cam gear in place

with the belt but putting forward tension on. This will set the first cam

in time with the crank.

Keep working the belt forward over to the right cam. When you get there

also crank the right cam to the timing mark and loop the belt over it. At

that point the belt is more or less in place. Put some tension on the belt

with the tensioner. It helps if you mark the place on the tensioner

adjustment of where it was when you started the job because that will be a

very close to the correct tension. I use the lock nut to mark this point.

Crank the engine over by hand - I remove the spark plugs just to make it

easier. As you come up on TDC check to see if both cam marks line up.

They

may not and if so you will have to back the belt off and set them up. It

is

not necessary to remove the belt and start over at that point as you can

just loosen the tension and work the belt backwards. You will probably

find

that due to slack in the belt on the first pass that you are off a tooth on

one gear or the other. It is easier if this is the right cam gear - but no

matter just back it off and reset it. The second time it will be easier as

the belt will now have been stretched out a little and the previous slack

will not throw you off.

Once the marks line up I turn the engine over 5 or ten times by hand to seat

the belt and then use the tool to set the tension. Turn the engine over 10

times more by hand and check the tension. The tension on a 16 valve engine

should be 4.5 on the gauge.

I have a page posted of things not to do that may help you.

http://www.kondratyev.com/porsche/belt_-78-84.htm

Dan B,

=============

VERY important. Many people make that mistake. The engine MUST be at TDC when measuring timing belt tension (0|T marker). Any other point will show the wrong value and your belt will probably be too loose. Also, never turn the engine back if you overshoot TDC, not even 1mm. If you do, the tension value you get will be wron