The smog pump is a low-pressure, high-volume, engine-driven, blade-type air

pump. Its purpose on vehicles equipped with a two-way cat (CO and HC) is to

pump air into the exhaust manifolds under certain conditions in order to

continue the burning process and reduce HC and CO emissions. On vehicles

equipped with a three-way cat (HC, CO and NOx) it pumps air into the cat in

order to assist the cat's reduction of these pollutants.

Wally Plumley

928 Specialists

================

The air pump is there to help exhaust gas emissions improve, especially at idle. Some 928 owners had trouble with the pump and deleted it. It takes only little energy from the engine so you could consider to keep it and fix the bearings when they fail.

Here's the device connection we are talking about:

Connection B - C will be made in the valve when connection A has a vacuum and

the catalytic converter will be supplied with fresh air. So when the throttle

closed it is blowing fresh air into the exhaust.

The vacuum in the intake will break down when the throttle is opened, so that

the diverter valve will close line C and switch over to connection D. Fresh air

will then pass to the air filter and be drawn in from there by the engine.

Versions introduced for 1983 models

If you have exhaust gas check on annual inspection you may need to stop the pump pushing air (O2) into the exhaust. This will make the Lambda value show excessive O2 and could trigger a fault condition (Lambda should be at 1 and obviously if you push extra air the lambda value will be off).

It easy to unplug the vacuum line that opens the valve. At

high vacuum (car in idle or little gas) the valve sends air into the exhaust to

burn existing HC and CO, at low vacuum (when the throttle valve is opened about

4 degrees) it sends air into airfilter.

If you leave the vacuum connection open you may lose vacuum so plugging it with

a stick of cone makes sense. Doing this is easier that removing the hose I

think.

Theo

1992 Porsche 928 GTS Midnight blue

The Netherlands

http://jenniskens.livedsl.nl

http://928gts.jenniskens.eu

=====

At 09:08 AM 4/24/01, Gerhard Van Zyl wrote:

>I recently had to change the fan belt on my '84 928S because it broke. The PO had replaced the air pump with a jockey pulley to

accommodate the cooling fan belt. The bearings on the jockey pulley seized, the shaft slid out, and the belt broke.

>I got a used air pump and replaced the jockey pulley with it.

>

>My questions are:

>1. Is this the right terminology for this pump?

Yes.

>2. What are the functions of this pump?

The air pump is a high-volume, low-pressure vane pump that pumps air into

the exhaust system to help burn pollutants.

>3. Where do the pipes on this pump connect to?

The inlet to the pump comes from the air pump filter, located low on the

right side on the inner fender panel on early cars, and top center above

the radiator on later cars.

The outlet of the pump is routed to the exhaust system, except on overrun

(coast), when it is dumped into the bottom of the air filter housing

instead. The routing is done by a valve located near the right valve cover.

>4. Does this pump have any influence on performance?

Very, very little. The pump requires very little power to turn, and the air

pumped in the exhaust doesn't affect the engine at all.

>Also, when one purchase a maintenance kit (Tune Up Kit) for the 928, it includes an "Additional Pump Filter" or "Air pump

Filter" amongst other things. Could you please tell me what this Air pump filter is for, if it is related to the above mentioned air pump, and where it goes?

The air pump filter keeps dirt out of the pump to improve its life. On your

car, there should be a metal canister (with a wing nut!) on the right

side of the engine compartment, at about the front of the tire, down low

(inside the engine compartment). On later cars, the filter is top center of

the radiator.

Wally Plumley

928 Specialists

===============

Greg,

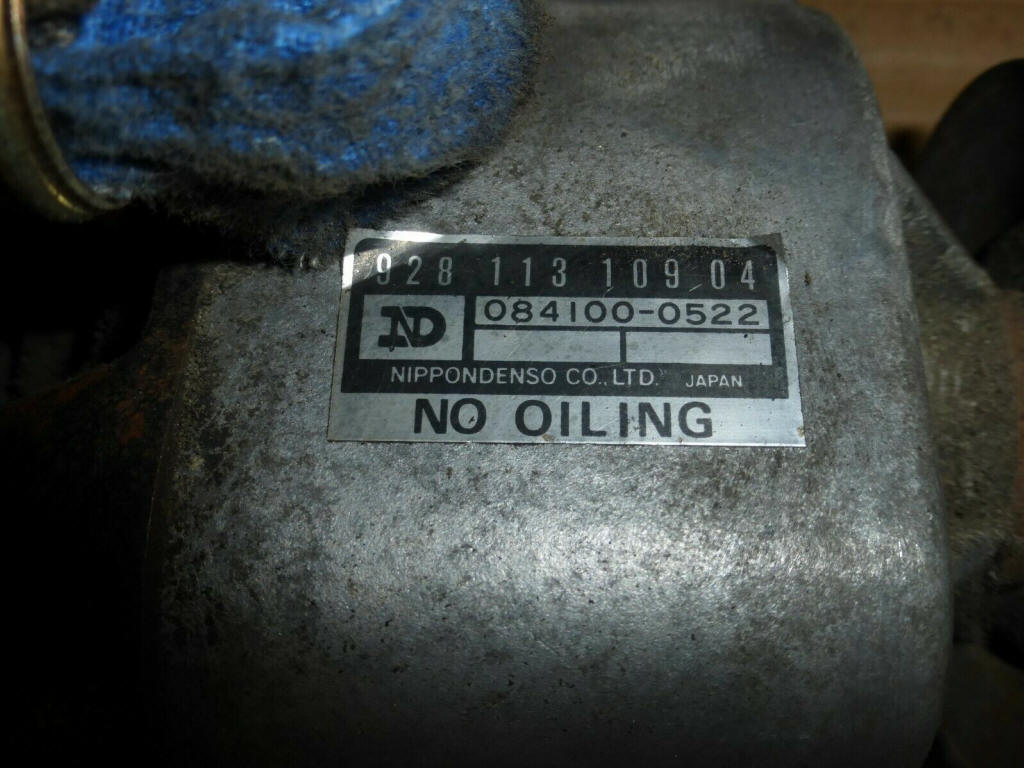

I rebuilt mine with a bearing from a local bearing shop. The number I used

is BCA203-FF 6203-2RS.

The important number is the 6203-2RS. Mine cost $5.56. There may be a Ford

bearing, but this one does not scream at me like the old one.

Ken

=========

Disassembly procedure: http://members.rennlist.com/mgrasser/

http://members.rennlist.com/mgrasser/airpumprebuild.htm

How does one get the pulley mounting piece off the shaft? Checked Mark

Grasser's page and he goes right by it. Got the pulley off fine, but

can't get any further on the front.

Glen

'80 Euro S

Glen,

Step 2. I don't remember it but if I made a tool for it it wasn't easy.

Simply a flat piece of 1/4inch steel with three holes. Still in my "special

tools" drawer.

Step 2: I made a puller to remove the pressed on bushing which the pulley bolts

to. It is a piece of 1/4 x 2 inch steel about 12 inches long. Three holes were

drilled to match the threaded holes in the bushing. By gradually tightening the

bolts and installing a 1/4 inch nut under it after bottoming out I was easily

able to remove it.

Mark Grasser

78 928 #358

==========Mark,

Color me confused...

I removed the belt pulley (three bolts) and there's the hub. Like six holes on

it with three threaded. In the middle is a thing I'd expect to be a hut or bolt.

Unfortunately, it's round with a small round hole in the middle. Several tries

with vice grips could not unscrew the "bolt"

from the hub, or hub from shaft or anything.

On your page for this, and in the notes below, it sounds like the special tool

removes the bearing from the case. Or is the hub pressed on?

Mine was squeaking. With the back off and paddles out, it still does.

It sounds like it's the "scaper" bar along the barrel. Just would like to clean

and lube the insides. I'm just using it as a tensioner with the rest of the

piping removed. Paddles are in the out basket.

Glen

'80 Euro S

> I removed the belt pulley (three bolts) and there's the hub.

Like six holes on it with three threaded. In the middle is a thing I'd expect to

be a hut or bolt. Unfortunately, it's round with a small round hole in the

middle.

I think the piece you speak of here is actually the shaft and yes I think it is

pressed on. The tool is used to press the shaft out. The three bolts on the

puller go into the threads in the flange.

> Mine was squeaking. With the back off and paddles out, it still

does. It sounds like it's the "scaper" bar along the barrel. Just would like to clean and lube the insides. I'm just using it as a

tensioner with the rest of the piping removed. Paddles are in the out basket.

When you get it apart simply remove the paddles and toss them.

===============

Ken Postma posted the following on 5/14/2002:

"I rebuilt mine with a bearing from a local bearing shop. The number I used is

BCA203-FF 6203-2RS. The important number is the 6203-2RS. Mine cost $5.56. There

may be a Ford bearing, but this one does not scream at me like the old one."

As for a belt to use, bypassing the pump, Todd posted this on 3/14/2006:

"I found a belt that works perfectly - a GATES 6821 Lawnmower drive belt - which

was green and not toothed. It also looked a little too fat, but it works great.

No problems after two years and several thousand miles of driving, no noticeable

wear on the belt, no squealing. It has stayed perfectly tight. Since there is no

adjustment you have to loosen then fan bracket, slip the belt on, then it will

go tight as you bolt the fan bracket back on.

Gates 6821. If you cant find it at the auto store, check Sears!"

I remember I rebuilt mine years ago at low cost. The tricky part is that when

you disassemble the pump it has some weird parts that you better photograph

before you take them apart or you may never figure out how to put it back

together. You will need bearing pulling tools to complete the job.

Dan Shapiro

'82 5 speed

========

Differences in fitting (connecting) the air pump:

ROW 16V and USA '78-'79 pump air into the back of the heads which exits at

the exhaust ports to reduce leftover hydrocarbons. AFAIK, these engines have

stainless steel liners to protect the port.

USA '80 and some ROW markets did not have an air pump.

USA '81-'95 (also '86 euro 32V) pump air into the rear 1/3 of the cat(s), to

reduce NOx.

ROW 32V '87-'95 pump air into the head at each exhaust port, using external

plumbing, just under the exhaust manifolds. USA '87-'95 use one of these ports

on each side for a temp sensor, to determine if there has been an ignition

failure, and turns off the fuel injectors on that side, to protect the cats.

Porken

===

Originally Posted by PorKen View Post

Notice that only USA '87-up have the sensors, not ROW. ROW don't need to protect

the cats, because they don't got none (most markets).

It's difficult to be precise due to the differing configurations of S4+ ROW cars

over time (Europe especially) But as a general rule I think it is safe to say

that all S4+ ROW cars that were fitted with cats from the factory got the

exhaust gas temp monitors. The ROW S4+ that weren't fitted with cats from the

factory didn't get it.

The S4 was designed to be readily configurable to have cats or not have cats.

Removing the Airpump (Worlds most complicated idler pulley for the engine driven

cooling fan) is easy on a cat equipped S4+ - only two readily accessible

connections to the cats to block up (if you don't remove the cats at the same

time)

Removing the air pump and all it's associated plumbing on an S4+ that came

without cats is more involved. I haven't yet figured out whether you can remove

the air injection manifold from under the exhaust manifolds without first

removing the engine.

__________________

Jon in OZ

===