I have had a problem with the electric rear hatch release for the longest

time, until I spoke to Dave Roberts over the phone yesterday.

Problem: motor engages, but does not release the hatch

turned out there was a poor alignment (and inclination angle) between the two

parts of the latching system. basically, the two parts were not parallel

enough (if such a position exists). Following Dave Roberts advice,

adjusting

the angle of the top part by inserting 2 pennies corrected the angle and

solved the problem.

thanks Dave, for your 2 cents advice .. literally

Tarek

86.5 Auto Indischrot

Hi Theo,

Nummer-----------Teil-----Stk-------Preis Auto Ahrens ( 2006 )

928 512 161 02----Riegel----1-------1,81

928 512 165 02----Nietstift--1-------0,61

928 512 163 02----Feder----1--------0,61

======================

Picture available upon request.

Hatch operation fix.

DISCLAIMER: Grab a beer, these instructions are for your reading enjoyment

only. Should you choose to follow these directions, you do so at your own

risk.

I performed this fix on Jason's hatch in about 30 seconds.

When I took my hatch latch apart, I looked at all of the pieces.

Trying to decide which part would be the least strong, the most likely to

wear or fail.

This was after playing with trying to adjust the hatch release to no avail.

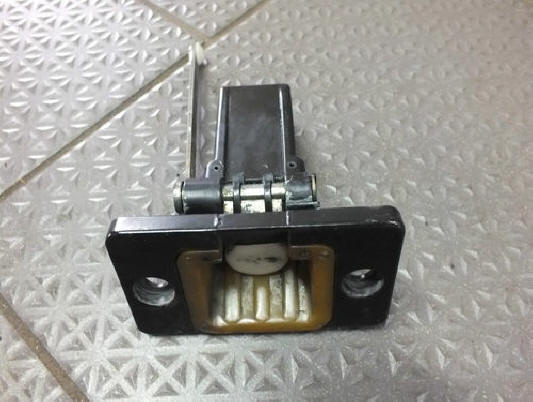

First, look at the upper part the "tongue", look for any stress

fractures.

If you do have stress fractures, welcome to the club, so do I. I'm fixing

my tongue before I put the latch back in. "Somehow that just doesn't

sound

right ;o) "

If you upper latch is NOT cracked or broken:

The upper latch has the catch in it. When the catch is moved sufficiently

far backwards, the latch releases and the spring in the lower piece lifts

the hatch above the point where the catch holds the hatch down. This is only

about 1/4".

By locating the motor mounting location further down the release cam pushes

the catch further in, to allow the release.

There is a ribbed rubber insert in the lower half of the latch that holds

the tongue in position allowing the release.

It is this rubber part that is the softest material and I believe the weak

link in the electronic operation of the hatch release.

The rubber either has shrunk with age or has worn down.

1. I simply cut a 1" by 1 1/4" shim out of a MOBIL 1 15W-50 plastic

oil

container. It's the thickness of the shim that makes this work, and I don't

even know how this this is, but it seemed thick enough. "Any brand oil

container will probably work as well and Mobil 1" ;o)

This piece is inserted between the rubber insert in the lower piece and the

rear of the lower housing. Long length horizontal and the short side

vertical.

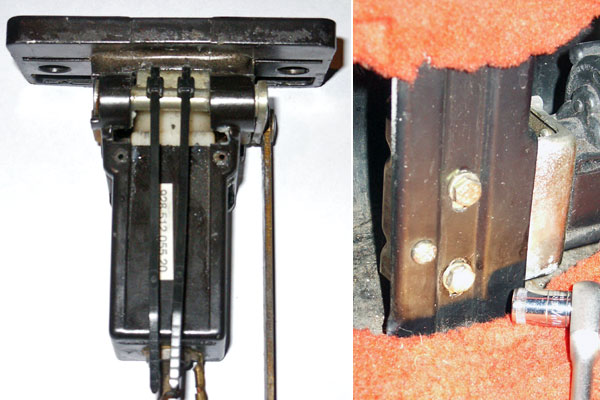

2. Open the hatch, remove the tool kit. Loosen the two motor mounting bolts.

Move the motor up as far as possible.

NOTE: This step is to relieve stress on the tongue and hopefully prevent

stress fractures. CAUTION

3. On the lower part of the latch, push the rubber cup at the rear, forward

into the latch area. Slide the shim in between the rubber piece and the rear of the housing.

This slightly moves or holds the tongue forward so that the catch is moved

far enough into the tongue to release. Depending on the age and wear of your

particular hatch, additional shims could be placed in this area.

4. You can either tighten the motor mounting bolts at the top and test the

hatch. Followed by incrementally moving the motor mounting location down

until the hatch starts operating, or follow the shop manuals;

a. Close the hatch.

b. Crawl into the hatch area, with the hatch closed and move the motor down

until the release cam just makes contact with the catch.

c. Tighten the mounting bolts.

5. If the hatch fails to release with the motor adjusted to the bottom.

Start over again at step 1.

Ken Postma '86 928S

=========

Brian,

If the latch does lock ok, but the release is not working at all then there is a

wear problem with either the plastic lock or with the metal release mechanism.

Again: it will fix a release problem... Not a locking problem!

Its like this:

The little motor runs to move a lever that turns a little metal strip in a way

that it pushes the white plastic lock from its locking place and thus releasing

the hatch. Its either the plastic lock or the metal piece that pushes the white

lock down which causes the problem, probably due to wear of either or both

parts. (oh yeah.. First try adjusting by positioning the mechanism more up or

down).

I made 3 little tie-wraps around the metal strip that pushes the plastic latch

down. You will have to take out the mechanism in the trunk to get to it, but it

is effectively 5 mins work or maybe 10 if it's the first time you do this. I

tried the same with sort of a jacket using a "poster" strip (plastic u-shaped

strip to hold a poster to the wall). That did last only a few month's though.

Tie wraps work a lot better. If the tie wraps ever wear you just put on new

ones.

If I'm confusing you or not very clear in what to do, please tell me, since I'm

trying to replace fairly common Dutch words by English descriptions here and

this might look ridiculous ;-))

Regards,

Theo

'88 928s4 cherry red

The Netherlands

=========

I have just changed my white latch piece. My symptom was the rear hatch not

opening - I think this is what happens when the white piece wears. I am not sure

that your problem (hatch not locking) is a symptom of the white piece wearing.

Maybe if it was completely broken, this would cause this.

Anyway, I found that I needed to remove the lock cylinder from the assembly.

There is a very small lock screw that you remove, then rotate the lock cylinder

about 20 degrees, then push. Once removed you can now withdraw the white piece.

Re-assemble in reverse.

Now, trying to spread the "rivet" head in the new pin is a problem. I am sure if

you had some sort of press you could do it. I tried the hole-punch and hammer

method; felt as though I would hurt something so stopped. I have left the pin

"floating" in there. With the grease applied, it has not drifted at all - I have

been checking.

I hope this helps . . .

Joshua Breckeen

Whitwell, Hertfordshire

email@jbreckeen.org <mailto:email@jbreckeen.org>

=========

>Since I bought my 928 a couple months ago, the power hatch release hasn't

worked--the mechanism seems to work just fine, but it doesn't succeed in

>releasing the latch. None of the moving parts look terribly worn, but all I can

figure is that the little cam that depresses the tongue of the latch is just

>barely worn enough that it won't depress the tongue far enough to unlatch. The

hatch also seems to squeak and rattle an awful lot when I drove over >bumps. As

far as seals, stops, etc. are concerned the only thing that seems to be worn is

the insert in the female part of the latch that looks like it was >carved out of

an ancient bar of hand soap, and is of similar structural integrity, i.e. it has

gone from somewhat crumbly to entirely disintegrated since I >bought the car. Is

the degradation of this insert related to either of my problems described above?

>

>Thanks,

>Joe Elliott

>'88 S4

Joe,

The first piece to replace it the plastic piece in the upper latch. They can be

ordered from Porsche and maybe the big three. Dave Roberts is a good source on

these small parts. Get the pin as you will have to drill it out to remove the

plastic piece.

What occurs over time is the plastic part wears causing the hatch to not latch

as tightly as new. Less tension keeps the hatch from pushing up enough when the

latch is released.

There are other issues such as adjustment, but unless the plastic upper latch is

almost new you will spend hours getting the hatch adjusted to release. And then

the hatch will probably not close tight enough to keep out the water.

If the latch wears enough the hatch can pop open when hitting a bump.

Dan the Pod Guy

Portia's Parts

============

The nylon actuator on the hatch should be centered. Is the hatch release hitting

the nylon release completely? I used a magic marker to mark the nylon piece. I

then actuated the release to visually check if the striker was hitting the

release. Porsche used a plastic catch on the upper latch thatís designed to

wear. Itís a replaceable, but be sure to get the pin with it. The upper hatch

piece is cast and cracks, flexes and becomes inop. Check the sides of the upper

latch, often the metal of the latch gets a hairline crack on the side and

prevents the motor from releasing the catch. Shim about 1/16" between the rear

side of the male part of the latch and the hatch. This moved the lower end

toward the front of the car, so it works. Use carbon paper to see where itís

contacting. When the catch is moved aft, the latch releases and the spring in

the lower piece lifts the hatch about ľ" above where the catch holds the hatch

down. By moving the motor further down the release cam pushes the catch further

in, allowing the release. A ribbed rubber insert in the lower half of the latch

holds the tongue in position allowing the release. The rubber is soft, shrinks

and wears with age. I inserted a 1"x1ľ" shim between the rubber insert in the

lower piece and the rear of the lower housing. Loosen the motor mount bolts, and

slide the motor up all the way. This relieves stress on the tongue and prevents

cracks. On the lower part of the latch, push the rubber cup at the rear, forward

into the latch area. Slide the shim between the rubber piece and the rear of the

housing. This moves the tongue forward so the catch is moved into the tongue.

Tighten the motor bolts at the top and test. Follow the manual by incrementally

moving the motor down until the hatch starts working. With the hatch closed,

move the motor down until the release cam just touches the catch. If the hatch

fails to release with the motor adjusted to the bottom, start over. The sheet

metal that the upper lock assembly bolts to gets bent so the black post is

pointed toward the rear. Shim to adjust the angle of the upper hatch mechanism

to point it farther back. This helps engage the lower mechanism and pop the

hatch. When the rear hatch lock breaks internally, to open the hatch crawl into

the rear, take the tool kit off, peel up the carpet at the center top section of

the panel behind the tool kit. Drill a ľĒhole in the very center of the panel as

high as possible still on the main body. Then insert a screwdriver to push back

the white plastic latch on the black post. It helps if someone pushes down on

the hatch to release the tension. The carpet covers the hole. The internal cast

metal arm of the lock isnít sold separately. Tried many adjustments without

success, until I read this tip: tape a piece of paper over the receiver; put

some grease on the tip of latch, and gently lower it until it makes a mark on

the paper. Note how far off center, and in which direction, the mark is; then

adjust the latch with shims until it comes down dead center.

Hatch release: The catch edge of the latch wears and prevents the hatch from

closing completely. With the remote release a small metal flap driven by a motor

pushes the catch back. The flap rotates 360į on each activation. This causes the

catch to clear the metal catch on the lower latch and then the spring in the

lower latch pushes the hatch up to clear the lower latch before the motor

releases the upper plastic catch. If there isnít enough clearance due to wear on

the upper plastic catch it wonít release. Also if the latch or hatch is binding

then the spring doesnít have enough strength to push up the hatch. Eventually

between the flap wearing into the plastic catch and the top edge wearing away

the flap cannot push the catch far enough back to release the hatch. There are

several fixes for this, but the best, easiest and most reliable way is to

replace the plastic catch in the top latch. Check that the fasteners are tight

on both the top and bottom part of the latch. There are two adjustments that may

be necessary. Remove the tool panel. Loosen the two 10 mm bolts that hold the

hatch release, and have an assistant trigger the release. Slide the release down

until it begins to drag at the bottom of the cycle, and slide it up until itís

just free. If this doesn't cure the problem, loosen the fasteners holding the

top latch to the hatch, and insert spacers under the outer edge so that the

latch is tilted forward. Make sure that the alignment allows the latch to enter

the receptacle cleanly. A used rear hatch rubber (plastic?) liner solved my

hatch problem where the hatch lid was squirming around and squeaking like crazy.

The liner deteriorates and cracks with age and eventually goes to pieces. With

all the other hatch problems that develop with age, a new unit the makes the

most sense. My symptom was the rear hatch not opening. I removed the lock

cylinder from the assembly. Thereís a small lock screw to remove, and then

rotate the lock cylinder about 20į, then push. Once removed you can withdraw the

white piece. Trying to spread the rivet head in the new pin is a problem. If you

had some sort of press you could do it. I tried the hole-punch and hammer

method; felt as though I would hurt something so stopped. I have left the pin

floating in there. With the grease applied, it has not drifted at all.

Hatch motor won't park is usually the release motor is running so freely that it

coasts over the cutout that should stop it. Possible cures:

1. Clean the cutout. Sometimes, there will be a build-up of copper on the disk that bridges the cutout, allowing just enough power flow to keep the motor running.

2. Pack the gearbox with grease, adding enough drag to slow the motor down so that it won't coast over the cutout.

3. I haven't tried it, but I would think that adding a power resistor in the run-on line before the motor might slow it down enough to solve the problem. Perhaps two ohms, 25 watt from Radio Shack?

4. Replace the

unit!

Jim Mayzurk

93 GTS 5-spd