Mechanical Gasoline Fuel-Injection System with Lambda

Closed-Loop Control

Data from Bosch

|

Bosch

K-Jetronic

|

|

Part 3

|

Electrical Circuitry

If the engine stops but the ignition remains switched on, the

electric fuel pump is switched off. The K-Jetronic system is

equipped with a number of electrical components, such as electric

fuel pump, warm-up regulator, auxiliary-air device, start valve

and thermo-time switch. The electrical supply to all of these

components is controlled by the control relay which itself is

switched by the ignition-start switch. Apart from its switching

functions, the control relay also has a safety function. A

commonly used circuit is described in the following.

Function

When cold-starting the engine, voltage is applied to the start

valve and the thermo-time switch through terminal 50 of the

ignition-start switch. If the cranking process takes longer than

between 8 and 15 seconds, the thermo-time switch switches off the

start valve in order that the engine does not "flood".

In this case the thermo-time switch performs a time switch

function. If the temperature of the engine is above about +35°C

when the starting process is commenced, the thermo-time switch

will have already open-circuited the connection to the start

valve, which as a result does not inject extra fuel. In this case

the thermo-time switch performs as a temperature switch. Voltage

from the start-ignition switch is still present at the control

relay, which switches on as soon as the engine runs. The

rotational speed reached when the starting motor cranks the engine

is high enough to generate the "engine running" signal

which is taken from the ignition pulses coming from terminal 1 of

the ignition coil. These pulses are processed by an electronic

circuit in the control relay, which switches on after the first

pulse and applies voltage to the electric fuel pump, the

auxiliary-air device and the warm-up regulator. The control relay

remains switched on as long as the ignition is switched on and the

engine is running. If the pulses from terminal 1 of the ignition

coil stop because the engine has stopped turning, for instance in

the case of an accident, the control relay switches off about 1

second after the last pulse is received. This safety circuit

prevents the fuel pump from pumping fuel when the ignition is

switched on but the engine is not turning.

Exhaust gas techniques

Exhaust-gas composition

Fuel combustion in the engine working cylinder is more or less

incomplete. The less complete the combustion, the higher is the

emission of toxic substances in the exhaust gas. Perfect, or

total, combustion of the fuel is impossible even when surplus air

is available in plenty. In order to reduce the load on the

environment, it is imperative that engine exhaust-gas emissions

are reduced drastically. All measures taken to reduce the toxic

emissions in compliance with a variety of legal requirements, aim

at achieving as clean an exhaust gas as possible, while at the

same time featuring optimum fuel-economy figures, excellent drive

ability, high mileage figures, and low installation costs. In

addition to a large percentage of harmless substances, the exhaust

gas of a spark-ignition engine contains components which are

harmful to the environment when they occur in high concentrations.

About 1 % of the exhaust gas is harmful, and consists of carbon

monoxide (CO), oxides of nitrogen (NOx), and hydrocarbons (HC).

The major problem in this respect is the fact that although these

three toxic substances are dependent upon the air-fuel ratio, when

the concentration of CO and HC increases the concentration of NOx

decreases, and vice versa.

Carbon monoxide

Carbon monoxide (CO) reduces the ability of the blood to absorb

oxygen and, as a result, lowers the blood oxygen content. This

fact, together with it also being colourless, odourless, and

tasteless, makes CO extremely dangerous. Even as low a proportion

as 0.3 percent by volume of CO in the air can prove fatal within

30 minutes. For this reason, it is forbidden to run an IC engine

inside closed rooms or halls without the extraction system being

in operation.

Oxides of nitrogen

Oxides of nitrogen (NOx) are also colourless, odourless, and

tasteless, but in the presence of atmospheric oxygen they rapidly

convert to reddish brown nitrogen dioxide (NO2)

which smells pungently and causes pronounced irritation of the

respiratory system. Due to the fact that NO2

destroys the lung tissue it is also detrimental to health when

encountered in higher concentrations. NO and NO2

are usually referred to together as NOx.

Hydrocarbons

A wide variety of hydrocarbons are present in the exhaust gas

from IC engines. In the presence of oxides of nitrogen and

sunshine they produce products of oxidisation. A number of

hydrocarbons are detrimental to health.

Catalytic after treatment

The toxic emissions of the spark-ignition engine can be

considerably reduced by the use of catalytic after treatment. The

exhaust-gas emission level of an engine can be influenced at three

different points. The first possibility of influencing the

emissions is during the mixture-formation stage before the engine.

The second possibility is the use of special design measures on

the engine itself (for instance, optimised combustion-chamber

shape). The third possibility is after treatment of the exhaust

gases on the exhaust side of the engine, whereby the task is to

complete the combustion of the fuel. This is carried out by means

of a catalytic converter which has two notable characteristics:

- The catalytic converter promotes the after burning of CO and

HC to harmless carbon dioxide (CO2) and water

(HO).

- At the same time, the catalytic converter reduces the

nitrogen of oxide present in the exhaust gas to neutral

nitrogen (N).

It is therefore perfectly clear that the catalytic after

treatment of the exhaust gas is considerably more effective than

for instance the purely thermal after burning of the exhaust gases

in a thermal reactor. Using a catalytic converter, more than 90%

of the toxic substances can be converted to harmless substances.

The three-way catalytic converter has come into widespread use

(here, the term "3-way" means that all three toxic

substances CO, HC and NOx are degraded at the same time). The

converter shell contains a ceramic "honeycomb" which is

coated with a precious metal, preferably with platinum and

rhodium. When the exhaust gas flows through this honeycomb, the

platinum and rhodium accelerate the chemical degradation of the

toxic substances. Only lead-free gasoline may be used with such

converters because the lead otherwise destroys the catalytic

properties of the noble-metal catalyst. This means that lead-free

gasoline is a prerequisite for the employment of catalytic

converters. The catalytic conversion principle presupposes that

the engine burns an optimum air-fuel mixture. Such an optimum, or

stoichiometric, air-fuel mixture is characterised by the

excess-air factor of Lambda= 1.00, and it is imperative that the

excess-air factor is maintained precisely at this figure otherwise

the catalytic converter cannot operate efficiently. Even a

deviation of only 1 % has considerable adverse effects upon the

after treatment. But the best open-loop control is incapable of

holding the air-fuel mixture within such close tolerances, and the

only solution is to apply an extremely accurate closed-loop

control, featuring almost zero lag, to the air fuel mixture

management system. The reason is that although an open-loop

mixture control calculates and meters the required fuel quantity,

it does not monitor the results. Here, one speaks of an open

control loop. The closed loop control of the mixture on the other

hand measures the composition of the exhaust gas and uses the

results to correct the calculated injected fuel quantity. This is

referred to as a closed control loop. This form of control is

particularly effective on fuel-injection engines because they do

not have the additional delay times resulting from the long intake

paths typical of carburettor engines.

Lambda closed-loop control

Lambda sensor

The Lambda sensor inputs a voltage signal to the ECU which

represents the instantaneous composition of the air-fuel mixture.

The Lambda sensor is installed in the engine exhaust manifold at a

point which maintains the necessary temperature for the correct

functioning of the sensor over the complete operating range of the

engine.

Operation

The sensor protrudes into the exhaust gas stream and is

designed so that the outer electrode is surrounded by exhaust gas,

and the inner electrode is connected to the atmospheric air.

Basically, the sensor is constructed from an element of special

ceramic, the surface of which is coated with microporous platinum

electrodes. The operation of the sensor is based upon the fact

that ceramic material is porous and permits diffusion of the

oxygen present in the air (solid electrolyte). At higher

temperatures, it becomes conductive, and if the oxygen

concentration on one side of the electrode is different to that on

the other, then a voltage is generated between the electrodes. In

the area of stoichiometric air-fuel mixture (Lambda = 1.00), a

jump takes place in the sensor voltage output curve. This voltage

represents the measured signal.

Construction

The ceramic sensor body is held in a threaded mounting and

provided with a protective tube and electrical connections. The

surface of the sensor ceramic body has a microporous platinum

layer which on the one side decisively influences the sensor

characteristic while on the other serving as an electrical

contact. A highly adhesive and highly porous ceramic coating has

been applied over the platinum layer at the end of the ceramic

body that is exposed to the exhaust gas. This protective layer

prevents the solid particles in the exhaust gas from eroding the

platinum layer. A protective metal sleeve is fitted over the

sensor on the electrical connection end and crimped to the sensor

housing. This sleeve is provided with a bore to ensure pressure

compensation in the sensor interior, and also serves as the

support for the disc spring. The connection lead is crimped to the

contact element and is led through an insulating sleeve to the

outside of the sensor. In order to keep combustion deposits in the

exhaust gas away from the ceramic body, the end of the exhaust

sensor which protrudes into the exhaust-gas flow is protected by a

special tube having slots so designed that the exhaust gas and the

solid particles entrained in it do not come into direct contact

with the ceramic body. In addition to the mechanical protection

thus provided, the changes in sensor temperature during transition

from one operating mode to the other are effectively reduced. The

voltage output of the sensor, and its internal resistance, are

dependent upon temperature. Reliable functioning of the sensor is

only possible with exhaust-gas temperatures above 350°C (unheated

version), and above 200°C (heated version).

Heated Lambda oxygen sensor

To a large extent, the design principle of the heated Lambda

sensor is identical to that of the unheated sensor. The active

sensor ceramic is heated internally by a ceramic heating element

with the result that the temperature of the ceramic body always

remains above the function limit of 250°C. The heated sensor is

equipped with a protective tube having a smaller opening. Amongst

other things, this prevents the sensor ceramic from cooling down

when the exhaust gas is cold. Amongst the advantages of the heated

Lambda sensor are the reliable and efficient control at low

exhaust-gas temperatures (e.g. at idle), the minimum effect of

exhaust-gas temperature variations, the rapid coming into effect

of the Lambda control following engine start, short

sensor-reaction which avoids extreme deviations from the ideal

exhaust-gas composition, versatility regarding installation

because the sensor is now independent of heating from its

surroundings.

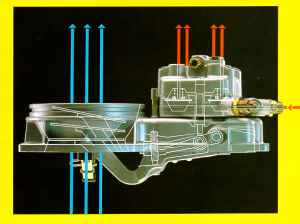

Lambda closed-loop control circuit

By means of the Lambda closed-loo control the air-fuel ratio

can be maintained precisely at Lambda= 1.00. The Lambda

closed-loop control is an add-on function, which, in principle,

can supplement every controllable f uel-management system. It is

particularly suitable for use with Jetronic gasoline-injection

systems or Motronic. Using the closed-loop control circuit formed

with the aid of the Lambda sensor, deviations from a specified

air-fuel ratio can be detected and corrected. This Control

principle is based upon the measurement of the exhaust-gas oxygen

by the Lambda sensor. The exhaust-gas oxygen is a measure for the

composition of the air-fuel mixture supplied to the engine. The

Lambda sensor acts as a probe in the exhaust pipe and delivers the

information as to whether the mixture is richer or leaner than

Lambda= 1.00. In case of a deviation from this Lambda= 1.00

figure, the voltage of the sensor output signal changes abruptly.

This pronounced change is evaluated by the ECU which is provided

with a closed loop control circuit for this purpose. The injection

of fuel to the engine is controlled by the fuel-management system

in accordance with the information on the composition of the

air-fuel mixture received from the Lambda sensor. This control is

such that an air-fuel ratio of Lambda= 1 is achieved. The sensor

voltage is a measure for the correction of the fuel quantity in

the air-fuel mixture. The signal which is processed in the

closed-loop control circuit is used to control the actuators of

the Jetronic installation. In the fuel-management system of the

K-Jetronic (or carburettor system), the closed-loop control of the

mixture takes place by means of an additional control unit and an

electromechanical actuator (frequency valve). In this manner, the

fuel can be metered so precisely that depending upon load and

engine speed, the air-fuel ratio is an optimum in all operating

modes. Tolerances and the ageing of the engine have no effect

whatsoever. At values above Lambda = 1.00, more fuel is metered to

the engine, and at values below Lambda = 1.00, less. This

continuous, almost lag-free adjustment of the air-fuel mixture to

Lambda= 1.00, is one of the prerequisites for the efficient after

treatment of the exhaust gases by the downstream catalytic

converter.

Control functions at various operating modes

Start

The Lambda sensor must have reached a temperature of above 350°C

before it outputs a reliable signal. Until this temperature has

been reached, the closed-loop mode is suppressed and the air-fuel

mixture is maintained at a mean level by means of an open-loop

control. Starting enrichment is by means of appropriate components

similar to the Jetronic installations not equipped with Lambda

control.

Acceleration and full load (WOT)

The enrichment during acceleration can take place by way of the

closed loop control unit. At full load, it may be necessary for

temperature and power reasons to operate the engine with an

air-fuel ratio which deviates from the Lambda = 1 figure. Similar

to the acceleration range, a sensor signals the full-load

operating mode to the closed-loop control unit which then switches

the fuel-injection to the open-loop mode and injects the

corresponding amount of fuel.

Deviations in air-fuel mixture

The Lambda closed-loop control operates in a range between

Lambda = 0.8 ... 1.2, in which normal disturbances (such as the

effects of altitude) are compensated for by controlling 1 to 1.00

with an accuracy of ±1 %. The control unit incorporates a

circuit, which monitors the Lambda sensor and prevents prolonged

marginal operation of the closed-loop control. In such cases,

open-loop control is selected and the engine is operated at a mean

Lambda-value.

|