Mechanical Gasoline Fuel-Injection System with Lambda

Closed-Loop Control

Data from Bosch

|

Bosch

K-Jetronic

|

|

Part 2

|

Fuel Management

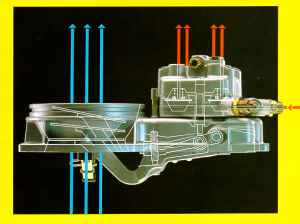

Mixture control unit

The task of fuel management is to meter, or allocate, the

correct quantity of fuel which corresponds to the amount of air

drawn in by the engine. Fuel management carried out by the mixture

control unit. This comprises the air-flow sensor and the fuel

distributor.

Air-flow sensor

The air-flow sensor operates according to the suspended-body

principle and measures the amount of air drawn in by the engine.

All the air drawn in by the engine flows through an air-flow

sensor which is connected upstream of the throttle plate. The

air-flow sensor is fitted with an air funnel in which is located a

movable sensor plate (the suspended body). The air drawn in

through the air funnel shifts the sensor plate by a certain amount

out of its zero position. The movement of the sensor plate is

transmitted to a control plunger by a lever system. This plunger

determines the quantity of fuel required. Considerable pressure

shocks can occur in the intake system if backfiring takes place in

the intake manifold. For this reason, the airflow sensor is so

designed that the sensor plate can swing back in the opposite

direction, past its zero position, and thus open a relief

cross-section in the funnel. A rubber buffer limits the swing-back

in the downward direction (in the case of the updraft air-flow

sensor, the swing-back in the upwards direction is also limited by

a rubber buffer). A leaf spring ensures that the sensor plate

assumes the correct zero position when the engine is stationary.

The sensor-plate movements are transmitted to the control plunger

in the fuel distributor by means of a lever system. The weight of

the sensor plate and the lever system are balanced by a

counterweight.

Fuel distributor

The fuel distributor meters (allocates) the correct amount of

fuel to the individual cylinders in accordance with the position

of the air-flow sensor plate. As already mentioned, the position

of the sensor plate is a measure of the amount of air drawn in by

the engine. The position of the plate is transmitted to the

control plunger by a lever. The control plunger controls the

amount of fuel which is to be injected. Depending upon its

position in the barrel with metering slits, the control plunger

opens or closes the slits to a greater or lesser degree. The fuel

flows through the open section of these slits to the differential

pressure valves and then to the fuel-injection valves. If

sensor-plate travel is only small, then the control plunger is

only lifted slightly and as a result only a small section of the

slot is opened for the passage of fuel. With larger plunger

travel, the plunger opens a larger section of the slits and more

fuel can flow. There is, therefore, a linear relationship between

sensor-plate travel and the slit section in the barrel, which is

opened for fuel flow. The force applied to the control plunger by

the sensor plate travel is opposed by another force, which comes

from the so-called control pressure. One of the functions of this

control pressure is to ensure that the control plunger follows the

movements of the sensor plate immediately and does not, for

instance, stay in the (upper) end position when the sensor plate

moves back down again. Further important functions of the control

pressure are discussed in the chapters dealing with warm-up and

full-load enrichment

Control pressure

The control pressure is tapped off from the primary pressure

through a restriction bore, which serves to decouple the

control-pressure circuit and the primary pressure circuit from one

another. A connection line joins the fuel distributor and the

warm-up regulator (control pressure regulator). When starting the

cold engine the control pressure is about 0.5 bar. As the engine

warms up, the warm-up regulator increases the control pressure to

about 3.7 bar. The control pressure acts through a damping

restriction on the control plunger and thereby develops the force,

which opposes the force of the air in the air-flow sensor. In

doing so, the restriction dampens a possible oscillation of the

sensor plate, which could result due to pulsating air-intake flow.

The control pressure influences the fuel distribution. If the

control pressure is low, the air drawn in by the engine can

deflect the sensor plate further. This results in the control

plunger opening the metering slits further and the engine being

allocated more fuel. On the other hand, if the control pressure is

high the air drawn in by the engine cannot deflect the sensor

plate so far and, as a result, the engine receives less fuel. In

order to fully seal off the control pressure circuit with absolute

certainty when the engine has been switched off, and at the same

time to maintain the pressure in the fuel circuit, the return line

of the warm-up regulator is fitted with a non-return valve. This

(push-up) valve is actually in the primary-pressure regulator and

is held open during operation by the pressure-regulator plunger.

When the engine is switched off and the plunger of the

primary-pressure regulator returns to its zero position, the

non-return valve is closed by a spring.

Differential-pressure valves

The differential-pressure valves in the fuel distributor serve

to hold the drop in pressure at the metering slits constant. The

air-flow sensor has a linear characteristic. This means that if

double the quantity of air is drawn in, the sensor-plate travel is

also doubled. If this (linear) travel is to result in a change of

delivered fuel in the same relationship, in this case double the

travel = double the quantity, then a constant drop in pressure

must be guaranteed at the metering slits independent of the amount

of fuel flowing through them. The differential-pressure valves

maintain the drop in pressure at the metering slits constant

independent of fuel through flow. The difference in pressure is

0.1 bar, this facilitates a high degree of control accuracy. The

differential-pressure valves are of the flat-seat type. They are

fitted in the fuel distributor and one such valve is allocated to

each metering slit. The upper and lower chambers of the valve are

separated by a diaphragm. The lower chambers of all the valves are

connected with one another by a ring main and are subjected to the

primary pressure (delivery pressure from fuel-supply pump). The

valve seat is located in the upper chamber. Each upper chamber is

connected to a metering slit and its corresponding fuel-injection

line. The upper chambers are completely sealed off from each

other. The diaphragms are spring-loaded and it is this helical

spring that produces the pressure differential. If more fuel flows

into the upper chamber through the metering slit, the diaphragm is

bent downwards and enlarges the valve cross-section at the outlet

line leading to the injection valve until the differential

pressure of 0.1 bar set by the spring again prevails. If less fuel

flows, the diaphragm bends back towards its original position and

decreases the valve cross-section at the outlet line until the

differential pressure of 0.1 bar is again present. This causes an

equilibrium of forces to prevail at the diaphragm which can be

maintained for every quantity of fuel by controlling the valve

cross-section.

Mixture formation

The formation of the air-fuel mixture takes place in the intake

manifold (tubes) and cylinders of the engine. The continually

injected fuel coming from the injection valves is

"stored" in front of the intake valves. When the intake

valve is opened, the air drawn in by the engine carries the

waiting "cloud" of fuel with it into the cylinder. An

ignitable air-fuel mixture is formed during the induction stroke

due to the swirl effect.

Mixture Adaptation

In addition to the basic functions described up to now, the

mixture has to be adapted during particular operating conditions.

These adaptations (corrections) are necessary in order to optimise

the power delivered, to improve the exhaust-gas composition and to

improve the starting behaviour and driveability

Cold start

Depending upon the engine temperature, the start valve injects

extra fuel into the intake manifold for a limited period during

the starting process. During cold starting, part of the fuel in

the mixture drawn in is lost due to condensation on the cold

cylinder walls. In order to compensate for this loss and to

facilitate starting the cold engine, extra fuel must be injected

at the instant of start-up. This extra fuel is injected by the

start valve into the intake manifold. The injection period of the

start valve is limited by a thermo-time switch depending upon the

engine temperature. This process is known as cold-start enrichment

and results in a "richer" air-fuel mixture, i.e. the

excess-air factor is temporarily less than 1.

Start valve

The start valve is of the solenoid-operated type. The winding

of an electromagnet is fitted inside the valve. In the inoperated

state, the movable armature of the electromagnet is forced against

a seal by means of a spring and thus closes the valve. When the

electromagnet is energised, the armature which as a result has

lifted from the valve seat opens the passage for the flow of fuel

through the valve. From here, the fuel enters a special nozzle at

a tangent and is caused to rotate. The fuel is particularly well

atomised by this specially shaped nozzle - the so-called

"swirl nozzle" - and enriches the air in the intake

manifold, downstream of the throttle valve, with fuel.

Thermo-time switch

The thermo-time switch limits the injection period of the start

valve dependent upon engine temperature. It is comprised of an

electrically heated bimetal strip which depending upon its

temperature either opens or closes an electric contact. The

complete device is fitted into a hollow threaded pin which in turn

is located at a position where typical engine temperature

prevails. The thermo-time switch determines the injection period

of the start valve. In doing so, the warming-up of the switch due

both to the engine heat and to the surrounding temperature, as

well as its in-built electrical heating filament are the

determining factors. The in-built heating facility is necessary in

order to limit the maximum start-valve injection period. The

mixture would otherwise become too rich and the engine would not

start due to "flooding". During cold start the injection

period depends mainly upon the electrical heating facility.

(Switch off at -20°C after approx. 8 seconds). On the other hand,

when the engine is already warmed-up the heat from the engine has

heated the thermo-time switch to such a degree that it remains

permanently open. As a result, an engine which is already at

operating temperature is not provided with extra fuel for

starting.

Warm-up

Warm-up enrichment is controlled by the warm-up regulator. When

the engine is cold the warm-up regulator reduces the control

pressure to a degree dependent upon engine temperature and thus

causes the metering slits to open further. At the beginning of the

warm-up period which directly follows the cold start, some of the

injected fuel still condenses on the cylinder walls and in the

intake ports. This can cause combustion miss to occur. For this

reason, the air-fuel mixture must be enriched during the warm-up

phase (Lambda<1.0). This enrichment must be continuously

reduced along with the rise in engine temperature in order to

prevent the mixture being over-rich when higher engine

temperatures have been reached. The warm-up regulator

(control-pressure regulator) is the component which carries out

this mixture control for the warm -up period by changing the

control pressure.

Warm-up regulator

The change of the control pressure is effected by the warm-up

regulator which is so fitted to the engine that it ultimately

adopts the engine temperature. In addition, the warm-up regulator

is electrically heated which enables it to be precisely matched to

the engine characteristic. It comprises a spring-controlled flat

seat diaphragm-type valve and an electrically heated bimetal

spring. In the cold state the bimetal spring exerts an opposing

force to that of the valve spring and, as a result, reduces the

effective pressure applied to the underside of the valve

diaphragm. This means that the valve outlet cross-section is

slightly increased at this point and more fuel is diverted out of

the control-pressure circuit in order to achieve a low control

pressure. As soon as the engine is cranked the bimetal spring is

heated electrically and after starting it is also heated by the

engine. The spring bends, and in doing so reduces the force

opposing the valve spring which, as a result, pushes up the

diaphragm of the flat-seat valve. The valve outlet cross section

is reduced and the pressure in the control-pressure circuit rises.

Warm-up enrichment is completed when the bimetal spring has lifted

fully from the valve spring. The control pressure is now solely

controlled by the valve spring and maintained at its normal level.

The control pressure is about 0.5 bar at cold start and about 3.7

bar with the engine at operating temperature.

Auxiliary-air device

In order to overcome the increased friction in the cold state

and to guarantee smooth idling, the engine receives more air-fuel

mixture during the warm-up phase due to the action of the

auxiliary-air device. When the engine is cold, the frictional

resistances are higher than when it is at operating temperature.

These must also be overcome by the engine during idle. For this

reason, the engine is allowed to draw in more air by means of the

auxiliary-air device which by-passes the throttle valve. Due to

the fact that this auxiliary air is measured by the air-flow

sensor and taken into account for fuel metering, the engine is

provided with more air-fuel mixture. This results in idle

stabilisation when the engine is cold. In the auxiliary-air device

a perforated plate is pivoted by means of a bimetal spring and

changes the open cross section of the bypass line. Dependent upon

temperature the plate assumes a given position, so that in the

case of a cold engine a correspondingly larger cross section of

the bypass line is opened. As the temperature increases the open

area is decreased until, finally, it is closed completely. The

bimetal is heated electrically. This means that the opening time

can be limited according to engine type. The auxiliary-air device

is so located that it is heated up by the engine to the engine

temperature. This ensures that the auxiliary-air device does not

respond when the engine is warm.

Load conditions

The adaptation, or correction, of the air-fuel mixture to the

operating conditions of idle, part load and full load is carried

out by means of appropriately shaping the air funnel in the

air-flow sensor. If the funnel had a purely conical shape, the

result would be a mixture with a constant air-fuel ratio

throughout the whole of the sensor plate range of travel (metering

range). As has already been mentioned though, it is necessary to

meter to the engine an air-fuel mixture which is optimal for

particular operating conditions such as idle, part load and full

load. In practice, this means a richer mixture at idle and full

load, and a leaner mixture in the part-load range. This adaptation

is achieved by designing the air funnel so that it becomes wider

in stages If the cone shape of the funnel is flatter than the

basic cone shape (which was specified for a particular mixture,

e.g. for Lambda= 1) this results in a leaner mixture. If the

funnel walls are steeper than in the basic model the sensor plate

is lifted further for the same air throughput, more fuel is

therefore metered and the mixture is richer. Hence, the funnel is

so shaped that a richer mixture is produced at idle and full load,

and a leaner mixture at part load (full-load and idle enrichment).

Mixture enrichment by means of control-pressure reduction In

those cases where engines are operated with a very lean mixture in

the part load range, an extra mixture enrichment must be provided

at full load in addition to the mixture adaptation resulting from

the shape of the air funnel. This extra enrichment is carried out

by a specially designed warm-up regulator. This regulates the

control pressure depending upon the manifold pressure. In this

model of the warm-up regulator, two valve springs are used instead

of one. The outer of the two springs is supported on the housing

as is the case with the normal-model warm-up regulator. The inner

spring though, is supported on a diaphragm which divides the

regulator into an upper and a lower chamber. The manifold pressure

is effective in the upper chamber which is connected to the intake

manifold, behind the throttle valve, by means of a hose. Depending

upon the model, the lower chamber is subjected to atmospheric

pressure either directly or by means of a second hose leading to

the air filter. Due to the low manifold pressure in the idle and

part-load ranges, which is also present in the upper chamber, the

diaphragm lifts to its upper stop. The inner spring is now at

maximum pretension. The pretension of both springs, as a result,

determines the particular control pressure for these two ranges.

When the throttle valve is opened further at full load, the

pressure in the intake manifold increases, the diaphragm leaves

the upper stops and is pressed against the lower stops. The inner

spring is relieved of tension and the control pressure reduced by

the specified amount as a result. In this manner, mixture

enrichment is achieved.

Acceleration response

The good acceleration response is a result of the sensor plate

"overswing". Acceleration During the transition from one

operating condition to the other, changes in the mixture ratio

occur which are utilised to improve the driveability. If at

constant engine speed the throttle valve is suddenly opened, the

amount of air which enters the combustion chamber, plus the amount

of air which is needed to bring the manifold pressure up to the

new level, flow through the airflow sensor. This causes the sensor

plate to briefly "overswing" past the fully opened

throttle point. This "overswing" results in more fuel

being metered to the engine (acceleration enrichment) and ensures

good acceleration response.

Controlling the air-fuel mixture

In order to adapt the injected fuel quantity to the ideal

air-fuel ratio of Lambda= 1, the pressure in the lower chambers of

the fuel distributor is varied. If for instance the pressure is

reduced, the differential pressure at the metering slots climbs

accordingly with the result that the injected fuel quantity is

also increased. In order to be able to vary the pressure in the

lower chambers, these are decoupled (in contrast to the

conventional K-Jetronic fuel distributor) from the primary

pressure. Decoupling is by means of a fixed throttle. A further

throttle connects the lower chambers with the fuel return. This

throttle is variable. If it is open, the pressure in the lower

chambers can reduce. If it is closed, the primary pressure is

present in the lower chambers. If this throttle is opened and

closed rapidly, it is possible to vary the pressure in the lower

chambers to correspond to the ratio between open time and close

time. An electromagnetic valve, the timing valve, is used as the

variable throttle. It is controlled by electrical pulses from the

Lambda control unit.

|