Bosch

K-Jetronic

|

|

Part 1

|

The Engine's Fuel Requirements

A spark-ignition engine needs a particular air-fuel ratio in

order to operate. The ideal air-fuel ratio is 14.7:1. Certain

operating conditions make it necessary to correct the mixture

accordingly.

The air-fuel ratio

Essentially, the power, the fuel consumption and the

exhaust-gas composition of a spark-ignition engine depend upon the

air-fuel ratio. Perfect ignition and perfect combustion only take

place within particular air-fuel ratios. In the case of gasoline

(petrol), the ideal air-fuel ratio is about 15:1. In other words,

15 kg of air are required for complete combustion of 1 kg of

gasoline (stoichiometric ratio). Deviations from this ratio affect

engine operation. The amount of fuel to be injected depends upon

load, engine speed and the particular exhaust-gas regulations in

force at the time. Depending upon the mode of operation, i.e.

idle, part load or full load, a different air-fuel ratio is

optimal in each case. Of decisive importance is the strict

adherence to the particular most favourable air-fuel ratio at any

one time.

The excess-air factor

The excess-air factor is identified by the symbol for Lambda.

Lambda = amount of air supplied ÷ theoretical air requirement

Lambda=1

This means that the amount of air supplied to the engine

corresponds to the theoretical amount of air required

(stoichiometric air-fuel ratio).

Lambda<1

This means air deficiency, or a rich mixture, and increased

power.

Lambda>1

This means air excess, or lean mixture, lower fuel consumption,

less power.

Lambda> 1.3

This means that the mixture will no longer ignite, the lean

misfire limit (LML) has been exceeded.

Fuel-management systems

Fuel-management systems, whether of the carburettor or

injection types, have the task of preparing an optimum air-fuel

mixture. Fuel management by means of manifold injection permits

the optimum adaptation of the air-fuel mixture to every operating

phase of the engine. It also ensures a lower level of pollutants

in the exhaust gas.

In spark-ignition systems, fuel management is by means of

either a carburettor or a fuel-injection system. Although, up to

now, the carburettor has been the most commonly used method, there

has been a distinct trend in the last couple of years towards

manifold fuel injection. This trend came about due to the

advantages offered by fuel injection as regards the demands for

fuel economy, high performance and, last but not least, a lower

level of pollutants in the exhaust gas. These advantages are based

on the fact that manifold fuel injection permits extremely precise

metering of the fuel depending upon the operating conditions of

the engine and its load, and taking environmental effects into

account. With manifold fuel injection, the correct air-fuel ratio

is maintained so precisely that the pollutant level in the exhaust

gas is considerably lower. Since with this system, the carburettor

is no longer required, the intake paths can be optimally designed

and laid out. This results in better cylinder charge which in turn

leads to a more favourable torque characteristic.

What types of mixture formation are available using fuel

injection?

There are both mechanically and electronically controlled

systems available. The K-Jetronic is a mechanical fuel injection

system which injects continuously and which needs no form of drive

whatsoever.

Electronically controlled systems

The fuel is supplied by an electrically driven fuel pump which

develops the pressure necessary for injection. The fuel is

injected by solenoid-operated fuel-injection valves into the

cylinder intake ports. The injection valves are controlled by an

electronic control unit (ECU) and the amount of fuel injected

depends upon the length of time that they stay open. By means of

sensors, the ECU is provided with information about the operating

conditions of the engine and about the ambient conditions around

the vehicle. The basis for assessing the amount of fuel to be

injected is the amount of air drawn in by the engine. The

L-Jetronic is an electronically controlled fuel-injection system.

In the case of the L-Jetronic, the amount of air drawn in by the

engine is directly measured by an air-flow sensor. Electronically

controlled fuel-injection systems are dealt with in detail in the

Publication "Electronically Controlled Fuel Injection"

in the Bosch Technical Instruction series.

Mechanical systems

With mechanical fuel-injection systems, one differentiates

between those which require a drive from the engine and those

which do not. The engine-driven systems comprise a fuel-injection

pump with an integrated governor. Their principle of operation is

the same as that of the fuel-injection systems for Diesel engines.

The other variation of the mechanical system is one which needs no

drive and which injects continuously. This system, the K-Jetronic,

is described in the following.

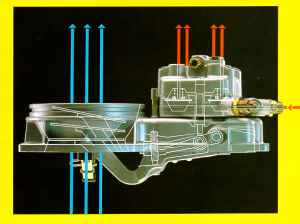

The K-Jetronic

The K-Jetronic is a mechanical fuel injection system from

Bosch. It is divided into three main functional areas:

- Air-flow measurement

- Fuel supply

- Fuel induction

Air-flow measurement

The amount of air sucked in by the engine is controlled by a

throttle valve and measured by an air-flow sensor.

Fuel supply

An electrically driven fuel pump delivers the fuel to the fuel

distributor via a fuel accumulator and a filter. The fuel

distributor allocates this fuel to the injection valves in the

cylinder intake tubes.

Fuel induction

The amount of air, corresponding to the position of the

throttle plate, sucked in by the engine serves as the criteria for

the metering of the fuel to the individual cylinders. The amount

of air sucked in by the engine is measured by the air-flow sensor

which, in turn, controls the fuel distributor. The air-f low

sensor and the fuel distributor are assemblies which form Part of

the mixture control unit. Injection takes place continuously, that

is, without regard to the position of the intake valve. During the

intake-valve closed phase, the fuel is "stored" in the

intake tubes.

Fuel supply

Outline of system

The fuel is drawn out of the fuel thank by an electrically

driven fuel pump. It is then forced, under pressure, through a

pressure accumulator and a fine filter to the fuel distributor,

which is located in the mixture control unit. The pressure is held

constant by a pressure regulator in the mixture control unit from

where it flows to the fuel-injection valves. The injection valves

inject fuel continuously into the intake ports of the engine

cylinders. The designation K-Jetronic stems from his fact

("K' stands for the German word for "continuous").

When the intake valves open, the air-fuel mixture is drawn into

the cylinders. The individual subassemblies of the fuel-supply

system are described in the following

Electric fuel pump

The electric fuel pump is a roller-cell pump the electric motor

of which is permanently surrounded by fuel. The fuel pump is

driven by a permanent magnet electric motor. The rotor disc which

is eccentrically mounted in the pump housing is fitted with metal

rollers in notches around its circumference which are pressed

against the thrust ring of the pump housing by centrifugal force

and act as seals. The fuel is carried in the cavities, which form

between the rollers. The fuel flows directly around the electric

motor. There is no danger of explosion, however, because there is

never an ignitable mixture in the pump housing. The pump delivers

more fuel than the maximum requirement of the engine so that the

pressure in the fuel system can be maintained under all operating

conditions. During starting, the pump runs as long as the ignition

key is operated. The pump continues to run when the engine has

started. A safety circuit is incorporated to stop the pump running

and fuel being delivered if the ignition is switched on but the

engine has stopped turning (for instance in the case of an

accident).

Fuel accumulator

The fuel accumulator maintains the pressure in the fuel system

for a certain time after the engine has been switched off. When

the engine is running it serves to deaden the noise of the

electric fuel pump. After the engine has been switched off, the

fuel accumulator maintains the pressure in the fuel system in

order to facilitate re-starting, particularly when the engine is

hot. The design of the accumulator housing is such that it deadens

the noise from the fuel pump when the engine is running. The

interior of the fuel accumulator is divided into two chambers by

means of a diaphragm. One chamber serves as the accumulator volume

for the fuel, the other chamber contains a spring. During

operation the accumulator chamber is filled with fuel. This causes

the diaphragm to bend back against the force of the spring until

it is halted by the stops in the spring chamber. The diaphragm

remains in this position, which corresponds to the maximum

accumulator volume, as long as the engine is running.

Fuel filter

Due to the extremely close tolerances of various components in

the system, it is necessary to fit a special fine filter for the

fuel in order to guarantee faultless performance of the

K-Jetronic. The fuel filter retains particles of dirt which are

present in the fuel and which would otherwise adversely affect the

functioning of the injection system. The fuel filter contains a

paper filter element, which is backed up by a strainer. This

combination results in a high degree of cleaning being achieved. A

supporting plate is used to hold the filtering elements in place

in the filter housing. It is of utmost importance that the

direction of flow indicated on the housing is complied with. The

filter is fitted in the fuel line downstream of the fuel

accumulator.

Primary-pressure regulator

The primary-pressure regulator maintains the pressure in the

fuel system constant. The pressure regulator incorporated in the

fuel-distributor housing maintains the delivery pressure (=

primary pressure) at about 5 bar. Due to the fact that the fuel

pump delivers more fuel than the engine needs, a plunger shifts in

the pressure regulator and opens a port through which excess fuel

can return to the fuel tank. The pressure in the fuel system and

the force exerted by the spring on the plunger in the pressure

regulator balance each other out. If for instance, the fuel pump

delivers slightly less fuel, the plunger is shifted by the spring

into the corresponding new position and in doing so reduces the

open section of the port through which excess fuel flows back to

the tank. This means that less fuel leaves the system at this

point, and as a result the primary pressure in the system

increases to the specified value. When the engine is switched off,

the fuel pump also stops running. The primary pressure drops to

below the injection-valve opening pressure. The pressure regulator

closes the return-flow port and prevents further pressure

reduction in the fuel system.

Fuel-injection valve

The fuel-injection valves open at a certain pressure and inject

fuel into the intake tubes. The fuel is atomised by the

oscillation of the valve needle. The injection valves inject the

fuel allocated by the fuel distributor into the intake ports

directly in front of the intake valves of the cylinders. The

injection valves are secured in a special holder in order to

insulate them from engine heat. The insulation prevents vapour

bubbles forming in the fuel injection lines which would lead to

poor starting behaviour when the engine is hot. The injection

valves have no metering function. They open of their own accord

when the opening pressure of 3.3 bar is exceeded. They are fitted

with a valve needle which vibrates ("chatters") audibly

at high frequency when fuel is injected. This means that excellent

fuel atomisation is achieved, even with the smallest of injected

quantities. When the engine is switched off, the injection valve

closes tightly and forms a seal when the fuel-system pressure has

dropped below the injection-valve opening pressure. As a result,

no more fuel can drip into the intake ports after the engine has

been switched off.

|