|

|

|

How I got my AC back to cold from just

cool.

Sorry about the picture size but bigger is better in

this case.

Please let me know if this

helps anyone or if something needs adding or changing.

Graham

So here's the symptoms:

1: AC seems to work ok as

long as the outside temp is less than 25ºC.

2: The warmer it gets outside,

the warmer my AC gets.

What you will need:

8mm

socket

10mm socket

Philips screwdriver

short handled Philips

screwdriver

Elastoplast

1 mate with small hands

What I did:

After speaking to a few people I came

to the conclusion that I must have quite a few problems here all contributing to

the main one. Firstly I was sent a copy of the HVAC layout which turned out to

be not much use, as I seemed to have different colour pipes, but this might not

always be the case. Either way it will give you a rough idea of what is going

on.

Click here for HVAC layout in new window.

Behind the air

filter box is a AC pipe which in my case was very cold, this being the case then

I'm thinking that the problem has got to be somewhere under the dash (most of it

was, but not all as I found out later)

So after trying in just about every

motor spares shop for 20 miles and still hadn't been able to buy a vacuum tester

(why does nobody sell them over here?) I decided to try this without.

With

the engine running I removed the pipe off the check valve between the brake

booster and the 4 way connector. I had a good strong vacuum going in to the

check valve.

The vacuum coming out of the check valve was a lot weaker. So problem number 1 is found and at the same time the

biggest piece of luck happened. My check valve vibrates quite fast if it is just

sucking air and there is no vacuum. I don't know if this is normal but I decided

not to clean it with carb cleaner, in case it stops vibrating, and just buy a

new one. So now I've got myself a mini vac tester.

I then disconnected all

the lines off the 4 way connector except the one coming from the brake booster

(with my mini vac tester in line) and plugged the other 3 holes on the 4 way.

The check valve stops vibrating so I know the 4 way is not leaking.

Then I

connected the brake booster line (with check valve) directly to the line going

to the vac tank with a piece of rubber tube. After waiting a few minutes to

empty the vac tank my mini vac tester is still vibrating, but not as much. When

I disconnected the vac tank line I heard the air rush in so figured it must just

have a slight leak and I'll come back to that later. Problem number 2 is now

found.

Then I connected the brake booster (still with check valve) directly

to the black line going to the AC. After 5 mins of coffee drinking my little vac

tester was still vibrating violently. So I must have a vac leak somewhere and

I'm hoping its only the hot water valve as this is quite easy to get

to.

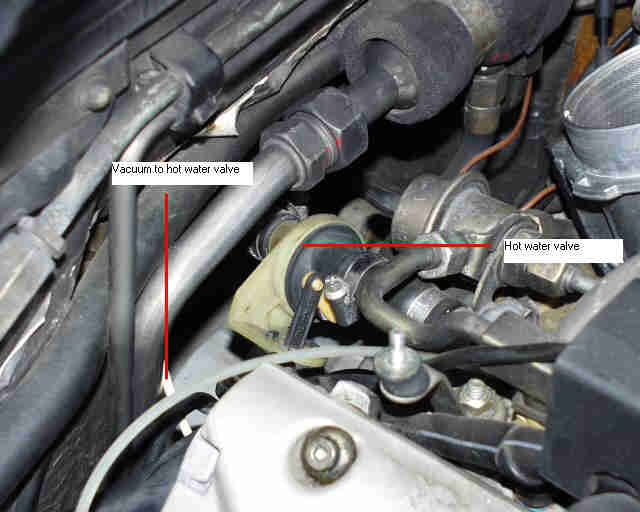

There are only 2 10mm bolts holding the air filter on so I removed it and

disconnected the white line from the hot water valve. There was virtually no

vacuum on this line so the hot water valve would have taken forever to close. I

decided to replace the valve anyway as its only about 10 mins work.

Now what I

was dreading has just happened!! The leak must be behind the dash

somewhere.

With the engine off I decided to remove the centre console side

panels and with a bit of luck it might just be a loose connection behind the

radio. If you have never removed these before its quite simple. There are 2

screws hidden in the carpet on each side panel and with these removed they just

slide out.

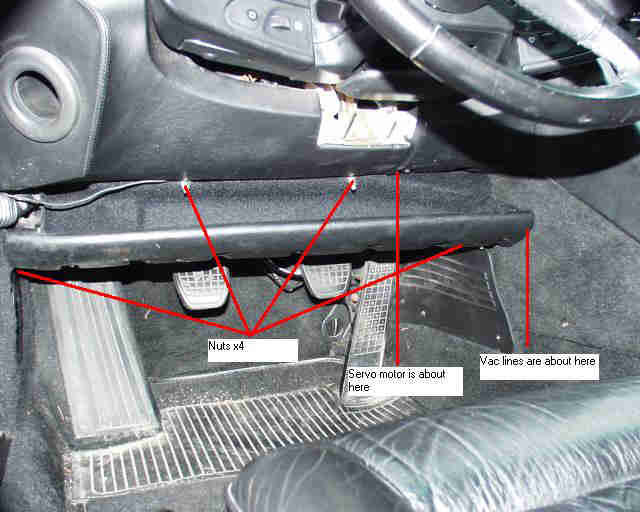

With the side panels out you will be able to see where all the vac lines

meet up. Sorry but I don't seem to have taken a picture here (anyone got one?),

but they are right at the back (see pic above).

While I was at it I thought I

might as well check the servo motor and the inside and outside temp sensor

setup.

The servo motor is behind the parcel shelf on the drivers side, sort

of above your right knee but further towards the front of the car. Some people

at this point decide to take out the seats but to me it just seemed like more

work for nothing.

This position worked for me.

There are 4 bolts holding

the parcel shelf in (2x 10mm 2x 8mm)

When the parcel shelf is

removed you should be able to see the servo motor

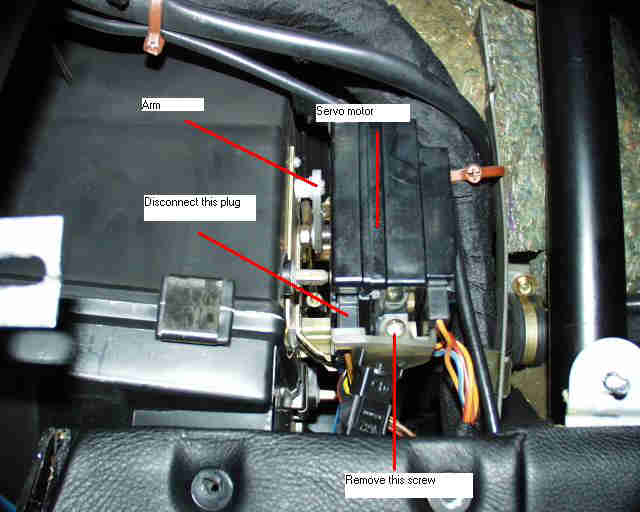

The servo motor has a little arm

which controls the temperature mixer flap. If the arm is all the way up, you get

max heat; all the way down, no heat. Normal position with the inside temperature

stable is roughly horizontal. I turned the ignition on and moved the temp slider

to see if it was moving ok. The motor being ok I moved on to the temp

sensors.

Here you will need an ohmmeter.

Disconnect the plug nearest to

the arm (after removing screw). Pin 4 connects to the outside temp sensor (in

the air duct to the alternator), which connects to the inside temp sensor

(behind the slotted fitting in the dash next to the glove box), which connects

to the temperature control slider. According to the manual, the resistance

between pins 4 and 12 should be about 3.7Kohms with the slider at 18, and about

4.7 Kohms with the slider at 30. If there is a break in this circuit or the

resistance is nowhere near these values, then you have probably got a faulty

temp sensor. The inside temp sensor has a small fan behind it to draw air in.

The fan can be tested by putting a lit cigarette near the sensor to see if its

drawing air.

With all these things checking out ok on mine I moved on to the

vac system.

With the side panels and parcel shelf removed you can see the

vacuum manifold behind the radio. There was nothing loose here so on with some

vac diagnostics.

I disconnected the black line which is the main vac feed and

plugged it. Having restarted the engine I went outside to see if my "mini vac

tester" was vibrating. No vibration on the check valve so I know that the vac is

ok up to this point.

I then connected the black line to the white line and

moved the sliders on the AC unit to different positions and checked my "vac

tester" for vibration. With the check valve not vibrating everything was looking

good, so I checked the hot water valve and sure enough it was opening and

closing as it should do.

I then repeated this with the green vac line

(defroster flap) and I could hear the flap move plus my "vac tester" was not

vibrating.

So with the green one checking out ok I moved on to the blue one

(fresh air flap). This was the one I was expecting a leak on but not looking

forward to having to replace.

Woohoo the 2nd piece of luck I've had so far.

Yet again I can hear the flap close plus my tester says all is ok.

If you

have a problem with the fresh air flap then see Tony's

tip.

Then I moved on to the orange line (comb flap behind centre vent)

but this time my "vac tester" keeps vibrating.

So I've found one leak but

I've still got one more to go.

Finally the yellow line (footwell flap) and it

appears I've got another vac leak.

So the verdict so far is that I have got a

vac leak on both the comb flap and the footwell flap actuators and/or the pipes

supplying the vacuum to them. So its on to removing the centre console.

I

thought this was gonna be worse than it actually was but it wasn't that

bad.

With the side panels already out remove the 2 screws at the window

switch end of the console (1 each side) and the 3 under the dash (2 drivers

side, 1 passenger side). Remove radio. Remove inside of ashtray. Gently pull out

the centre vent with your finger and remove the 2 bolts above the vent (see

pic).

Remove glovebox (4 bolts inside, 3 underneath), disconnect air feed to

glove box if you need to. Remove bolt securing centre console from inside

glovebox (see pic).

Bearing in mind that this is a manual 928 the gear stick boot

will just lift up if you pry it a little. If you haven't done it already this is

a good time to get a mate with small hands!

Disconnect AC unit plug, the

clock, cigar lighter, ashtray light and any other connectors that might cause a

problem. The window switches etc can be unplugged at the rear of the console

behind where the radio was.

GET ELASTOPLAST READY!

The console should now

come out with a bit of gentle persuasion. BE CAREFUL NOT TO BREAK ANYTHING

BEHIND INSIDE TEMP SENSOR.

I reconnected the black vac

line directly to the yellow line as before and restarted the engine. With my

mate outside checking my tester for vibration I removed the yellow line from the

actuator and plugged it. The check valve stopped vibrating so the leak had to be

in the actuator itself. This is a bit of a pain to replace so its easier just to

change the rubber diaphragm inside. With the new diaphragm in place it was time

for another vac test. The actuator arm moved instantly and my "tester" stopped

vibrating.

Click here to see the small slit in the diaphragm that caused

the leak.

This only left the comb flap (centre vent) actuator so I plugged

the line and confirmed that it was the actuator that was leaking and not the

orange line.

There's a great short cut on replacing the rubber diaphragm on

Tony's

site, as its worse than the other one to replace the whole thing, but I

decided just to plug the orange line as the comb flap doesn't actually do a lot

(plus the OPC didn't have a replacement at the time) I'll probably do it one

day.

With this line capped I then connected the vac lines back to their

correct positions on the vac manifold. This time all flaps are moving correctly

(except comb flap obviously), the hot water valve is closing and best of all my

mini vac tester is not vibrating anymore. I still cant believe how lucky I was

too have a check valve that did this!

So with the doors closed, the engine

running and Elastoplast on finger (trust me you'll know why if you have to do

this!) it was time for the real test. I pressed the AC button and instantly I

heard the flaps move and the air flow pick up. Most importantly I had the ice

cold AC that I used to have before. All that was left was to put everything back

in place and I was done.

With everything back together I then decided to

blast the front of the radiator with compressed air which cleared out all the

usual dead animals and things that these cars collect along the way ( I once had

a tangerine behind the air filter box)

The

conclusion

With the vac leaks in the AC system the fresh air

flap was failing to shut off the flow of outside air. The hot water valve was

also failing to stop the flow of hot water from the engine entering the heater

core. When the air from outside mixed with the air from the heater core and the

cold AC air, I was getting warm AC. This would probably explain why I was

getting steamed up windows when I first started the car.

Although I've

completely sussed out the workings of the HVAC, I couldn't have done this

without the initial advice of others (thanks Wally and Theo) and by spending a

lot of time reading some great sites like Greg's, Tony's and Theo's. But most of all a big thanks to Karl who has got small

hands and better eyes than I have (even though he does drive a BMW).

Hope

this helps some people out with their AC problems and maybe one day I'll put all

this stuff on its own site.

If anyone has any questions or whatever then feel

free to contact me.

Graham